widely used palm kernel oil refining process in tanzania

- Applicable Industries:Food Shop

- After-sales Service:Free spare parts

- Dimension (L*W*H):2900*1850*3950mm

- Production capacity:100-500 kg/h

- Voltage:380V

- Weight:1420kg

- Power:11-15kw

- Advantage:High Oil Yield

- Raw material range:mustard,gape seed,corn germ,sesame,baobab seed

- Transport Package: Container

- Function:Oil Production

palm oil refining processing plant palm oil refinery plant

palm oil is used widely for cooking due to its heat resistant property as compared to any other vegetable oil. the unique and best quality of palm is that it produces two types of oil: palm oil and palm kernel oil. palm oil is extract from the flesh of the palm fruit and palm kernel oil is extract from the seeds or kernel of the palm fruit.

widely used hot sale edible oil refinery plant for edible oil

new condition edible oil refining plant / crude oil refinery plant. the edible oil refining plant is widely used for various oil seeds, such as soybean, sesame, sunflower seed, peanut, cocoa bean, rape seed, etc. 2.features of new condition edible oil refining plant / crude oil refinery plant / palm kernel oil processing machine

palm kernel oil refining process

palm kernel oil refining process usually includes degumming, deacidification, decolorization, deodorization and fractionation. palm oil refining classification is based on different uses and requirements, the use of physical methods and chemical processes, removal of crude palm oil harmful impurities and unnecessary substances, get some.

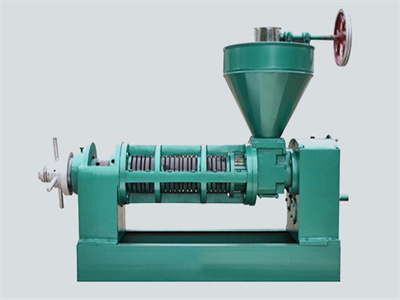

yzs-120 oil press machinery palm oil mill machine 30-60tpd cost

yzs-120 oil pressing machinery palm oil mill machine leading manufacturers and suppliers. the yzs-120 oil pressing machinery is an advanced oil press machine, the structure is simple, the operation is easy and convenient, wide suitability and continuous operation, high productivity and high oil output rate.what’s more, this type of o

palm kernel oil refining process flow chart and crude

refining is an essential process for a complete palm kernel oil processing process because there are still some impurities such as phospholipids, ffa, pigment, odor, etc. in the crude palm kernel oil.in order to gect high quality palm kernel oil and let palm oil is good for long time storage .

manufacture palm kernel oil refining process,low cost

palm kernel oil refining process is a extremely complicated process.palm kernel oil refining process consists of palm kernel oil degumming process.palm kernel oil deacidification process,palm kernel oil decolorization process and palm kernel oil deodorization process.and our palm kernel oil refining machine is widely used in peanut oil refining ,soybean oil refining,corn germ oil refining.

palm kernel oil production line, palm kernel oil extraction machine

for example, either single machine or production line are both for sale. our palm kernel oil production line’s capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil production and refining process design, manufacture, installation, commissioning and after-sales service if it is needed.

palm oil and palm kernel oil refining and fractionation

request pdf palm oil and palm kernel oil refining and fractionation technology crude oils contain non-triacylglycerol components that must be partially or totally removed in order to become.

how to refine palm kernel oil leading manufacturer

alkali neutralization; adds the mixture of liquid caustic soda (1.5% of crude palm kernel oil weight and with 160 baume) and the liquid sodium salt (0.5% of the crude palm kernel weight) into the crude palm kernel oil, then stir it rapidly at the speed of 60 r/min for about 10 to 15 minutes, and followed by the stirring slowly at the speed of 27 r/min for 40 minutes.

refining of palm kernel oil project topics

the crude palm kernel oil was first washed with distilled water by heating the mixture in an electric heater for about 2 hours to reduce the impurities present in the oil in their crude form, degummed with phosphoric acid and neutralized with naoh (caustic soda).the saponification value, iodine value and acid value was analyzed and their values.

palm oil mill process palm oil mill machine

palm oil mill processing gathering palm oil pressing, palm oil refining, and palm oil fractionation processing lines, ensures high efficiency and high oil yield of edible palm oil. palm oil pressing machine provides high oil yield crude palm oil refining machine.

high efficiency oil refining plant dansschool q

high efficiency palm kernel oil press machine refinery plant. palm kernel oil refining palm oil mill machine leadingpalm kernel oil contains soap grade and food grade.the process of palm kernel oil refinery is to refine.widely used hot sale building a cooking oil refinery plant.

palm oil mill plant edible oil press production line

11.palm kernel oil extraction: palm kernel oil extraction process includes crushing, flaking, steaming and frying, pressing. the production process and equipment is similar to that of the general oil.

processing

from refining crude palm oil, we produce refined, bleached and deodorised (rbd) palm oil which can be further processed into rbd palm olein and rbd palm stearin. rbd palm stearin is mainly used in the manufacturing of specialty fats and oleochemicals. palm kernel oil and coconut oil, also known as lauric oils, have a high proportion of lauric.

palm kernel oil press leaf filter china palm oil

hereby, i introduce one type high efficiency filtration equipment for palm kernel oil. press leaf filter is widely used in oil industry for crude oil filtration and refinery process. in terms of palm kernel oil, press leaf filter can realize 0.02% purity after filtration. this data can compete with press filter and other type filters.

palm kernel oil press machine automatic cold pressed oil machine

industrial grade fats (palm fat and tallow) and oils (palm kernel and coconut oil) were used and provided by jabonera potosina. the saponification number and the acid value were adjusted by mixing fats with oils. the caustic soda solution used was 27% w/w in water. sodium chloride and sodium sulphate were at industrial grade.

palm oil refining process flow chart and crude palm oil

the most widely used palm oil deacidification methods in vegetable oil refining industry are alkali refining and steam distillation. adsorption decolorization process: palm oil contains a lot of pigments, which affect the taste and sale of palm oil. in order to get higher quality palm oil, palm oil decolorization process is a must.

palm oil extraction process, methods, steps agri farming

palm oil types: red palm oil: red palm oil has been cold-pressed from the fruit of the oil palm and bottled for use as cooking oil, in addition to other uses such as being blended into mayonnaise and vegetable oil. white palm oil: white palm oil is the product of processing and refining. when refined, the palm oil loses its red color.

rbd palm kernel oil tradeasia international

rbd palm kernel oil is made from crude palm oil by physical refining, and crude palm oil is extracted from oil palm seeds. it is a solid in cold climates and semi-solid at room temperature. it is white. its melting point is between 25-27 degrees celsius. it has a sharp solid fat melting curve, making it a premium raw material for specialty fats.

what is palm oil and kernel oil is it bad for your health2>

palm oil is the most widely-used vegetable oil in the world. palm oil and palm kernel oil represent 33 per cent of all of the world’s production of vegetable oils, with soybean oil—at 27 percent—its nearest competitor 11). (50%) and (35%) supply 85 per cent of the palm oil used globally.