use oil refining two main processing steps nora in mumbai

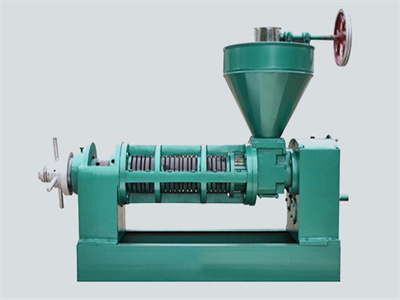

- Applicable Industries:Food Shop

- After-sales Service:Engineers available to service machinery overseas

- Dimension (L*W*H):3400*800*2000mm

- Production capacity:5 ton/day

- Voltage:380V/50HZ/Triple phase

- Weight:590kg

- Power:11-15kw

- Advantage:Best price

- Raw material range:palm kernel,peanut,pepper seed,rice bran,palm fruit

- Transport Package: Export Fumigation-Free Wooden Box

- Function:Oil Production

used oil re-refining: two main processing steps nora, an

used oil re-refining: two main processing steps. many years ago, re-refiners had difficulty recycling used oil to produce good-as-new lubricating oil products. but starting in the 1970’s, a series of technical innovations enabled the recycling industry to overcome the challenge, and re-refiners began to produce top quality lubricating products.

used oil re-refining nora, an association of responsible

the base oil is usually made by refining virgin crude oil. major refineries take in crude oil and process it to make gasoline, diesel fuel, jet fuel, asphalt and in some cases, lube base oil. not all refineries have the equipment to extract and purify the lube base oil from crude, but there are many that do.

the three stages of oil refining planète énergies

during the process, which is also known as topping (refining) another name for atmospheric distillation., the oil is heated at the bottom of a 60-meter distillation column at a temperature of 350 to 400°c, causing it to vaporize. the vapors rise inside the column while the heaviest molecules, or residuals, remain at the bottom, without vaporizing.

9.10.1.1 sugarcane processing

sweetwaters from other refinery steps and is steam heated. the resultant syrup is passed through a screen to remove any particulate in the syrup and sent to the clarification step. the syrup from the crystal washing, called affination syrup, is transferred to a remelt processing station or reused in the raw sugar washing step.

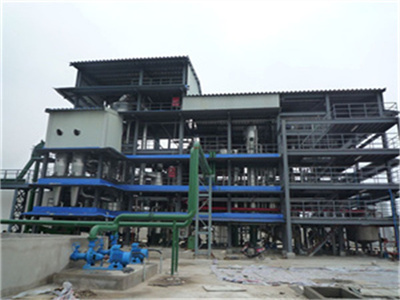

5tpd palm kernel oil processing project palm oil extraction

in order to make more money from palm oil processing business, he decided to set up a palm oil refinery palnt to propduce rbd palm oil and sell them to the market. after a long time discuss with our sales manager, he affirmed the requirement, to buy a set of semi-continuous palm oil refining machine with 5tpd capacity.

palm fruit threshing processing machinery equipment

the palm fruit receive the palm oil mill as fruit bunch which is embedded with many small individual fruits. in the threshing station of palm oil mill, the individual fruits will be detached from the bunch by use of ffbs thresher/stripper. rotating drum and fixed drum are the two main threshing machine applied in palm oil milling process.

the 5 biggest chinese oil companies investopedia

china petroleum and chemical corp., known informally as sinopec, is an oil, gas, and chemical giant and is also one of the world's biggest corporations.the company ranked in the second spot on the

downstream refining oil gas pall corporation

throughout the refining operation, both scheduled and unscheduled maintenance activities are major contributors to operational downtime. regardless of the process, whether it be alkylation, caustic treatment, feedstock filtration, or anything else, contamination poses significant risks that can result in extensive and costly downtime.

the three stages of oil refining planète énergies

during the process, which is also known as topping (refining) another name for atmospheric distillation., the oil is heated at the bottom of a 60-meter distillation column at a temperature of 350 to 400°c, causing it to vaporize. the vapors rise inside the column while the heaviest molecules, or residuals, remain at the bottom, without vaporizing.

what kind of palm oil purification process is used in palm

palm oil purification process used in palm oil refinery plant refers to palm oil refining process. usually, there are two kinds: palm oil physical refining process and palm oil chemical refining process. due to their different features, these two kinds of refining method are used in different types of palm oil refinery plant.

the 5 biggest chinese oil companies investopedia

china petroleum and chemical corp., known informally as sinopec, is an oil, gas, and chemical giant and is also one of the world's biggest corporations.the company ranked in the second spot on the

managing, reusing, and recycling used oil reduce, reuse

the same consumers and businesses that use regular oil also can use re-refined oil, since re-refining simply re-processes used oil into new, high-quality lubricating oil. any vehicle maintenance facilities, automobile owners, and other machinery maintenance operations that use oil also can use re-refined oil.

how to extract cbd oil the extraction process how cbd oil

the first step is a process called winterization, followed by short path distillation. winterization this process is only needed when the oil was extracted at high press/high temperature (supercritical) because this intense extraction pulls everything from the plant, including material you don’t want in the final products.

edible oil refinery plant cooking oil refining machine

batch type edible oil refinery machine for sale batch oil refinery plant for edible_factory price vegetable oil machine. batch type edible oil refinery machine 2020-05-25 19:02 oil refining process chat online get price batch type edible oil refinery machine is the most widely used refining production line because of its low cost and small footprint.

an introduction to petroleum refining and the production of price

crude oil to the surface; moving crude oil from oil fields to storage facilities and then to refineries; moving refined products from refinery to terminals and end-use locations, etc.). refining adds value by converting crude oil (which in itself has little end-use value) into a range of refined products, including transportation fuels.

nigeria: as covid-19 delays dangote refinery oil import

the covid-19 pandemic has affected the completion of the dangote refinery and also crippled a critical segment of the ebute-metta to apapa segment of the lagos to ibadan rail project.

the three stages of oil refining planète énergies

during the process, which is also known as topping (refining) another name for atmospheric distillation., the oil is heated at the bottom of a 60-meter distillation column at a temperature of 350 to 400°c, causing it to vaporize. the vapors rise inside the column while the heaviest molecules, or residuals, remain at the bottom, without vaporizing.

what kind of palm oil purification process is used in palm

palm oil purification process used in palm oil refinery plant refers to palm oil refining process. usually, there are two kinds: palm oil physical refining process and palm oil chemical refining process. due to their different features, these two kinds of refining method are used in different types of palm oil refinery plant.

how to extract cbd oil the extraction process how cbd oil

the first step is a process called winterization, followed by short path distillation. winterization this process is only needed when the oil was extracted at high press/high temperature (supercritical) because this intense extraction pulls everything from the plant, including material you don’t want in the final products.

managing, reusing, and recycling used oil reduce, reuse

the same consumers and businesses that use regular oil also can use re-refined oil, since re-refining simply re-processes used oil into new, high-quality lubricating oil. any vehicle maintenance facilities, automobile owners, and other machinery maintenance operations that use oil also can use re-refined oil.

uganda: oil and gas boom in 2017

negotiations over uganda's oil refinery-- expected to be developed in two phases of 30,000 barrels-per-day each, with the first one expected to be completed in 2020--were halted when rt global

degumming process and technology of edible oil

gums——two main types hydratable phosphatides easy to remove non-hydratable phosphatides (nhp) hard to remove from oil some nhp removed with hydratables in water degumming requires the use of a acid to convert to hydratable for complete removal . water degumming process steps. heat oil to 60 70 ℃ water addition and mixing

an introduction to petroleum refining and the production of price

crude oil to the surface; moving crude oil from oil fields to storage facilities and then to refineries; moving refined products from refinery to terminals and end-use locations, etc.). refining adds value by converting crude oil (which in itself has little end-use value) into a range of refined products, including transportation fuels.

nigeria: as covid-19 delays dangote refinery oil import

the covid-19 pandemic has affected the completion of the dangote refinery and also crippled a critical segment of the ebute-metta to apapa segment of the lagos to ibadan rail project.

managing, reusing, and recycling used oil reduce, reuse

the same consumers and businesses that use regular oil also can use re-refined oil, since re-refining simply re-processes used oil into new, high-quality lubricating oil. any vehicle maintenance facilities, automobile owners, and other machinery maintenance operations that use oil also can use re-refined oil.

how to extract cbd oil the extraction process how cbd oil

the first step is a process called winterization, followed by short path distillation. winterization this process is only needed when the oil was extracted at high press/high temperature (supercritical) because this intense extraction pulls everything from the plant, including material you don’t want in the final products.

uganda: oil and gas boom in 2017

negotiations over uganda's oil refinery-- expected to be developed in two phases of 30,000 barrels-per-day each, with the first one expected to be completed in 2020--were halted when rt global

an introduction to petroleum refining and the production of price

crude oil to the surface; moving crude oil from oil fields to storage facilities and then to refineries; moving refined products from refinery to terminals and end-use locations, etc.). refining adds value by converting crude oil (which in itself has little end-use value) into a range of refined products, including transportation fuels.

practical handbook of soybean processing and utilization

the role of deodorization in processing and refining of edible fats and oils has long been accepted as the last step in preparing the oil for use as an ingredient in margarine, shortening, salad oil, cooking oil, hard butters for the confectionery industry, and many other products in the food industry.

environmental impacts of the oil industry

production and oil refining. it also addresses the issue of environmental risks in the industry and possible accidents that may arise from its activities. 1. introduction oil plays a vast and vital role in our society as it is organized today. oil represents much more than just one of the main energy sources used by mankind. besides being an

nigeria: as covid-19 delays dangote refinery oil import

the covid-19 pandemic has affected the completion of the dangote refinery and also crippled a critical segment of the ebute-metta to apapa segment of the lagos to ibadan rail project.

refinery news roundup: most refineries back

the government began the process of selling the refinery in late 2017. privately-owned sahara group said it is hoping to buy a 70% stake in the state-owned refinery.--tema oil refinery is now processing crude with a single furnace and the daily throughput is around 25,000-26,000 b/d, or around 55% of original capacity. upgrades. new and revised