sri lanka continuous discharge vegetable oil refinery equipment

- Applicable Industries:Manufacturing Plant, Farms

- After-sales Service:Field maintenance and repair service

- Dimension (L*W*H):1080*600*1180mm

- Production capacity:300-600 kg/h

- Voltage:380V

- Weight:1550kg

- Power:0.6kw

- Advantage:Best mnufacturer

- Raw material range:cotton seed,peanut,soybean,copra

- Transport Package: Container

- Function:Oil Production

buy and sell used edible oil plants perry process equipment uk

used vegetable oil extraction line 500-700 kg/h. stock as61952. used soya oil extraction line with capacity 500-700 kg/h. this small vegetable oil extraction line is composed of the following equipment: (2) extruders, 37 kw each. (2) oil screw presses, 22 kw each. (4) screw conveyors, 1.5 kw each (1)... location: europe. add to cart view details

map of edible oil refinery machine in the united kingdom

edible oil refinery machine map of health and safety issues. search and share locations of oil and gas refinery accidents, pollution, pipeline spills fires.

refining of edible oils uk

the problem edible oil refining is normally a high volume, continuous operation. the reagent additions are traditionally carried out using low shear static mixer or inline agitators, which can lead to several potential problems:

dhz series disc separator henan solid mechanical equipment

dhz series self-cleaning disc separator is used for the solid-liquid-liquid 3 phase separation.its widely used for continuous degumming,desoaping and water washing in the vegetable oil refinery process.

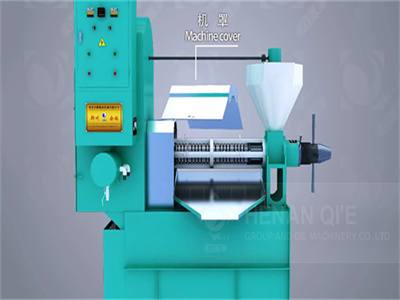

the technology of vegetable oil extraction edible oil press

extract oil by pressing is a traditional method of vegetable oil extraction. with the development of oil extraction technology, three types of oil extraction methods are created from manpower press, hydraulic press to screw oil press. the widely used oil machine today is the screw oil press, and the hydraulic oil press is still in use.

china glycerol refining equipment / small biodiesel plant

vegetable oil biodiesel production, biodiesel production machine, biodiesel plant waste oil manufacturer / supplier in china, offering glycerol refining equipment / small biodiesel plant from waste vegetable oil biodiesel production plant for sale, new design mobile disinfectant claimed to sterilize intelligent temperature measurement cabin with great price, disinfection door machines channel

faq about vegetable oil processing technology oil extraction

we company is a leading manufacturer specialized in cooking oil making machine with capacity 10-2000tpd.we can offer cooking oil press machine,oil extraction machine,oil refinery fractionation plant.

ab0cd sub-sectoral environmental and social guidelines

ab0cd sub-sectoral environmental and social guidelines: vegetable oil processing vegetable oil processing sub-sectoral environmental social guidelines page 1 august 2009 process description vegetable oils are extracted from seeds, beans, fruits and nuts. the basic steps in the process are shown in the figure below. seeds/ beans cleaning/drying/

refining of edible oils uk

the problem edible oil refining is normally a high volume, continuous operation. the reagent additions are traditionally carried out using low shear static mixer or inline agitators, which can lead to several potential problems:

drz series disc separator henan solid mechanical equipment

drz series manual discharge disc separator is mainly used for continuous degumming and water washing in the vegetable oil refinery process and also suitable for solid-liquid separation in other industry.

vertical leaf filter for factory price and hot sale vegetable oil

self-discharging filter/vertical leaf filter is suitable for the oil, chemical, pharmaceutical and etc in the production of decolored oil filter, clarification, filter, crystal filtration separation process. it particularly solved the problem of pressed oil is hard to filter and discharging in the cotton seed,rapeseed,mustard seed oil industry.

pennwalt

the pennwalt super-d-canter centrifuge is a specially developed continuous solid-bowl horizontal scroll discharge centrifuge for effective separation of slurries into clarified liquid and dewatered cake solid phases, with the application of centrifugal sedimentation principle.

alkali refining oil chemists&039; society

4.1. neutralisation of crude oil. this method has become established mainly in the for refining soybean oil, the so called long mix process. the process is a combination of degumming and neutralization. for the conditioning of the nonhydratable phosphatides, a small quantity of phosphoric or citric acid is added to the crude non-degummed oil.

oil purification sciencedirect

if refining is located in connection with an oil mill, refining of the miscella is possible. to follow this process, the extraction miscella is concentrated to 40–58% oil content ( cavanagh 1976 ). caustic soda (7–26 bé) is added to the miscella to hydrate the phosphatides, and the mixture is run over a homogenizer for 15 s.

about europa crown limited crown europe europa crown ltd

europa crown ltd. has rapidly acquired international recognition in the design, supply and start-up of oilseed processing and edible oil refining equipment. it is a wholly owned subsidary of crown iron works company of minneapolis, usa, established market leaders in solvent extraction and certain areas of preparation.

vertical leaf filter for factory price and hot sale vegetable oil

self-discharging filter/vertical leaf filter is suitable for the oil, chemical, pharmaceutical and etc in the production of decolored oil filter, clarification, filter, crystal filtration separation process. it particularly solved the problem of pressed oil is hard to filter and discharging in the cotton seed,rapeseed,mustard seed oil industry.

centrifugal separator centrifuges and separators

the fields of application range from separating processes in the chemical and pharmaceutical industries through oil and fat recovery to the production of dairy products, beer, wine, fruit and vegetable juices, as well as the processing of mineral oil and mineral oil products. separators have disk or annular chamber bowls.

sundex process engineers private limited oem manufacturer

established in 1982, we “sundex process eng. pvt. ltd” are reputed projects and service providers, engaged in offering a turnkey solution for solvent extraction plants, vegetable oil refinery plants, oil mill and oilseed processing plant. our expertise and experience in process equipment fabrication and project handling are well recognized

spill prevention, control, and countermeasure (spcc

or manufacturing equipment such as process vessels, or other equipment used in the alteration, processing or refining of crude oil and other non-petroleum oils, including animal fats and vegetable oils. 5. how do i determine if my facility could reasonably discharge oil into or upon navigable waters or adjoining shorelinesp>

oil purification sciencedirect

if refining is located in connection with an oil mill, refining of the miscella is possible. to follow this process, the extraction miscella is concentrated to 40–58% oil content ( cavanagh 1976 ). caustic soda (7–26 bé) is added to the miscella to hydrate the phosphatides, and the mixture is run over a homogenizer for 15 s.