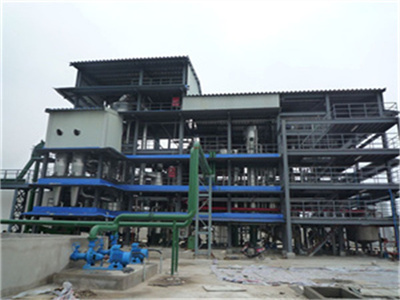

soybean edible oil refinery oil refinery in uganda

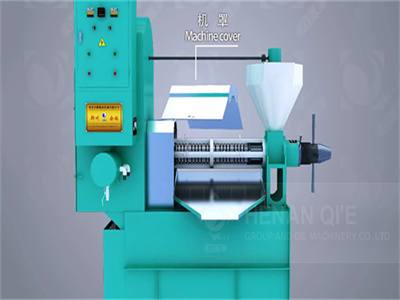

- Applicable Industries:Food Shop

- After-sales Service:Field maintenance and repair service

- Dimension (L*W*H):2260*1680*1680mm

- Production capacity:300 ton per day

- Voltage:380V/50HZ/3 phase

- Weight:1140kg

- Power:11KW

- Advantage:High Productivity

- Raw material range:castor,linseed,baobab seed,corn germ,sesame

- Transport Package: Wood

- Appearance:Vertical

edible oil refining method and technology information in vegetable oil refining process_tech edible oil refinery plant manufacturer supplies oil

a: palm oil refining is adopted to deep process crude palm oil by removing impurities like gum, acid, pigment and bad smell. palm oil refining can be divided into chemical refining and physical refining. a: if you want to set up a refined

soyabean oil refinery plant, soyabean oil refinery, soyabean oil refining, soyabean oil refining process

soyabean oil refinery by tinytech comes in various capacities ranging from entry level small scale plant of 5-tpd to medium and big scale plants upto 30-tpd. we are leading manufacturers and exporters of soyabean oil refinery plant systems for

soybean oil refining machinery_edible oil refinery plant

30tpd soybean oil refinery plantthe process of soybean oil refining is to refine the crude soybean oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to re soybean oil refining machinery date:2013-11-0

supply soybean oil,peanut oil,sunflower oil,palm oil,etc.edible oil refinery plant solutions_solution

different edible oil refinery plant has different functions, they can refine different kinds crude oil into refined edible oil. doing company provide different solutions to set up all kinds of edible oil refinery plant, such as palm oil refinery

edible oil refinery machine technology myande group

edible oil refinery technology the objective of refining is to remove objectionable co-constituents in edible oil with the least possible damage to glycerides and minimal loss of desirable constituents. methods of refining depend on nature and

edible oil refining method and technology information in vegetable oil refining process_tech edible oil refinery plant manufacturer supplies oil

a: the wax content of crude sunflower oil is about 0.06-0.1%, whose exist will have bad effect on sunflower oil taste and transparency. especially when cooking, high wax content sunflower oil produces smoke and strong smell. a: this continuous

how is edible oil refinedat is edible oil refining processedible oil refinery plant manufacturer supplies oil refining machine, oil

refined edible oil is obtained through further processed by series of machines in edible oil refinery plant.usually edible oil refining process includes degumming, deacidifaction, decolorization and deodorization four steps.

how to classify the grades of edible oilich grade of edible oil can i get after refining processch

take the palm oil as the example, if you use the same edible oil refinery plant to refine different ffa content crude palm oil, you will get different grade of refined palm oil. because the crude palm oil extracted from fresh palm fruit has

small edible oil coconut meat oil refinery plant

oil refinery stock ownership (tentative) rank name of owner percentage ownership 1 general electric of the united states 50.0 2 refinery holding company 19.5 3 jk minerals africa 10.0 4 total sa of france 10.0 5 petroleum

soyabean oil refinery plant, soyabean oil refinery, soyabean oil refining, soyabean oil refining process

soyabean oil refinery by tinytech comes in various capacities ranging from entry level small scale plant of 5-tpd to medium and big scale plants upto 30-tpd. we are leading manufacturers and exporters of soyabean oil refinery plant systems for

edible oil refinery machine technology myande group

edible oil refinery technology the objective of refining is to remove objectionable co-constituents in edible oil with the least possible damage to glycerides and minimal loss of desirable constituents. methods of refining depend on nature and

edible oil processing soybean oil refinery edible oil refinery equipment

we are leading manufacturer and exporter of cooking oil refinery edible oil refinery vegetable oil refinery refined cooking oil production vegetable oil processing edible oil processing palm oil refining edible oil refinery plant

edible oil refinery, vegetable oil refinery, cooking oil refinery, palm oil refinery, edible oil refining, vegetable oil refining, edible oil

edible edible oil refinery from tinytech is a masterpiece for oils fats. we develop uniquely designed economical refinery systems which are suitable and adaptable to majority of the masses as compared to those giant

soybean oil refinery machine for factory price and hot sale vegetable oil machine

soybean oil refinery machine 2024-07-02 09:37 oil refining process chat online get price 1-10tpd batch type soybean oil refinery machine henan doing company is the best soybean oil refinery machine manufacturer and supplier in china, with a

edible oil refinery, capacity: 5-20 ton/day, for peanut oil, rs 1000000 /set id: 7611218648

mitsun engineering offering edible oil refinery, capacity: 5-20 ton/day, for peanut oil at rs 1000000/set in vadodara, gujarat. read about company. get contact details and

edible oil refining method and technology information in vegetable oil refining process_tech edible oil refinery plant manufacturer supplies oil

a: palm oil refining is adopted to deep process crude palm oil by removing impurities like gum, acid, pigment and bad smell. palm oil refining can be divided into chemical refining and physical refining. a: if you want to set up a refined

soybean oil extraction plant soybean oil plant manufacturer oil processing plant suppliers refinery plant manufacturers

today, mectech is a leading soybean oil extraction plant manufacturer or soybean oil plant manufacturer and abroad with its latest techniques and energy efficient plants. being one of the leading soybean refined oil plant suppliers, we

10-15w edible oil refinery plant, capacity: 20-60 ton/day, id: 10313762073

sparktech offering 10-15w edible oil refinery plant, capacity: 20-60 ton/day in mumbai, maharashtra. get best price and read about company. get contact details and address id: 10313762073 this is an average seller rating received from buyers

small edible oil coconut meat oil refinery plant

oil refinery stock ownership (tentative) rank name of owner percentage ownership 1 general electric of the united states 50.0 2 refinery holding company 19.5 3 jk minerals africa 10.0 4 total sa of france 10.0 5 petroleum

edible oil refinery plant cooking oil refinery vegetable oil refinery

we are leading manufacturer and exporter of cooking oil refinery edible oil refinery vegetable oil refinery refined cooking oil production vegetable oil processing edible oil processing palm oil refining edible oil refinery plant

mectech is great soybean oil refining machinery manufactures, exporter and biggest edible oil refinery plant supplier in the world.… soybean

mar 22, 2019 mectech is great soybean oil refining machinery manufactures, exporter and biggest edible oil refinery plant supplier in the world. it also provides projects for

edible oil refinery/ soybean oil refinery/sunflower oil /palm oil refining machine

edible oil refinery/ soybean oil refinery/sunflower oil /palm oil refining machine 王学亮 loading... unsubscribe from 王学亮ncel unsubscribe working... subscribe subscribed unsubscribe 1

edible oil refinery, vegetable oil refinery, cooking oil refinery, palm oil refinery, edible oil refining, vegetable oil refinin degumming process

degumming process is part of vegetable oil refinery mainly to remove gums from crude edible oils like soyabean oil. degumming process equipments and plant are made by us. first stage of vegetable oil refining process degumming is the first

prominent edible oil press machinery, oil production planf refining plant manufacturer chemical refining and physical refining of vegetable oil

edible/vegetable oil refining is a step by step process. refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. the entire oil refining plant process comprises degumming/neutralization,

why to choose water degumming method in soybean oil refining processch

compare with other crude oil, soybean oil is with 2% phospholipid content, belongs to high phospholipid content oil. thus, the best way to remove gums in the soybean oil is water degumming method. in different soybean oil refinery plant , there

soybean oil extraction plant soybean oil plant manufacturer oil processing plant suppliers refinery plant manufacturers

today, mectech is a leading soybean oil extraction plant manufacturer or soybean oil plant manufacturer and abroad with its latest techniques and energy efficient plants. being one of the leading soybean refined oil plant suppliers, we

soybean oil refining detailed soybean oil refining process

soybean oil refining the crude soybean oil still contains many oil-insoluble and oil-soluble impurities that needs to be removed. soybean oil refining including degumming (removing of phosphatides), alkali refining (washing with alkaline