simple method for detersmallng the oil extraction process of seeds

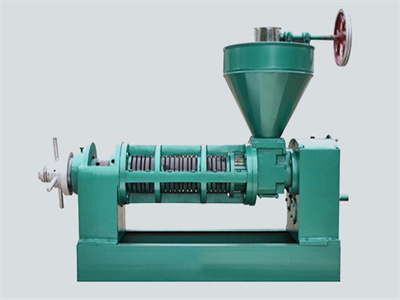

- Applicable Industries:Food & Beverage Factory, Food Shop

- After-sales Service:Free spare parts, Field installation

- Dimension (L*W*H):2250*1700*1700mm

- Production capacity:2-3 Ton/Day

- Voltage:220V

- Weight:195kg

- Power:Y315m-6-45kw

- Advantage:High Oil Yield

- Raw material range:rice bran,palm kernel,pine nut

- Transport Package: Wooden Case

- Equipment material:Stainless steel or carbon steel

sunflower oil extraction process, methods with low cost

sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. de-hulling is completed when the seed has a moisture content of 5% after cleaning.

survival manual how to extract oil from seeds

the methods of extracting the oil are simple. not all methods work for all sources. various seeds listed above can be used as a human food supply or for the oil... but not both. if you extract the oil from the seed the leftover is good for fuel or animal fodder but not good for you to eat. extracting the oil is done via a press method.

(pdf) extraction of date palm seed oil (phoenix

oil extraction from date palm seeds (iraqi date palm) is done by standard solvent extraction method using a soxhlet apparatus. this work is aiming to investigate the extraction of palm seed oil as.

a review of methods used for seed oil extraction

the solvent extraction method offers a number of advantages. bhuiya . et al. (2015) who researched on the optimization of oil extraction process fromn native beauty leaf seed (calophyllum innophyllum) reported that the solvent extraction process is a very effective method, with high yield and consistent

role of hexane in oil seed extraction pure chemicals co

hexane in solvent extraction method hexane in its pure form is a colorless liquid , and its boiling point is between 50℃ 70℃ all of which work in favor for oil extraction. to begin the process of solvent extraction, oil seeds (soybean, rapeseed etc.) are removed of impurities and dried to reduce moisture content.

solvent extraction oil chemists&039; society

in figure 2, it is worth noting that a plant to process rapeseed with pre-pressing followed by extraction will often reduce the oil content from about 40% to 20% in the presses and from 20% to 0.8% in extraction, and that (after adjustments for moisture changes during the process) the press oil produced may be roughly 25.8% of the raw seed.

oil extraction chemistry britannica

oil extraction, isolation of oil from animal by-products, fleshy fruits such as the olive and palm, and oilseeds such as cottonseed, sesame seed, soybeans, and peanuts.oil is extracted by three general methods: rendering, used with animal products and oleaginous fruits; mechanical pressing, for oil-bearing seeds and nuts; and extracting with volatile solvents, employed in large-scale.

(pdf) actual methods for obtaining vegetable oil from oilseeds

the purpose of those extraction methods was to optimize the process by collecting the maximum quantity of the existing oil in oilseeds with the minimum costs. discover the world's research 17.

5. seed extraction and cleaning

a sometimes effective method of extraction is to place the dried pods in a rotating drum or cement mixer with several large loose weights (e.g. stones, sand bags) which, when tumbled, break the pods and facilitate the release of seed. this technique is simple but slow and its effectiveness varies with species.

olive oil extraction methods, process, steps agri farming

olive oil is the oil obtained solely from the fruit of the olive tree to the barring of oils obtained using solvents or re‐esterification processes and of any mixture with oils of other kinds.. the olive is a fruit name. at its purest and best, olive oil is the ‘juice’ of this fruit—just crushes and presses the olives and it will drip free. . unfortunately, the process is infrequently.

your guide to ethanol extraction in cannabis cannabis

the second assumption is that two potential outcomes of yield exist from the extraction and refinement process (i.e., 10 percent and 15 percent of dried flower weight). the final assumption is the potential wholesale prices for high-quality refined oils, which we will estimate at two potential levels of $20 and $25 per gram.

how to extract cbd oil the extraction process how cbd

winterization is the process to remove undesirable elements that were extracted from the plant, for example fats, waxes, and lipids. this process is only needed when the oil was extracted at high press/high temperature (supercritical) because this intense extraction pulls everything from the plant, including material you don’t want in the final products.

extraction of vegetable oils from ground seeds by

extraction. solvent extraction is the most efficient method of removing the oil from the seed. it may take place either in batch or continuous process. the solvent extraction most commonly used today is percolation with a countercurrent flow using hexane as solvent [5]. the rate of extraction depends on the thickness and area of solid phase,

how essential oils are extracted ida's soap box

supercritical co2 extraction process. this method helps to maintain the integrity of the base constituents of the oil and produces a highly concentrated finished product without using petroleum solvents. petroleum solvent: a few years ago almost all absolutes, essential oils, and even carrier oils were extracted in this manner. however, since.

methods for extracting essential oils sciencedirect

the most commonly used extraction method is the steam distillation or water distillation method . this extraction process can last between 1 and 10 h. the amount of oil produced depends on length of distillation time, temperature, press, and type of plant material (naves, 1974). during distillation, plant materials are exposed to boiling.

extraction techniques of essential oil

the process, as a result, extracted oils have a more natural odor that is unmatched by distilled oils, which may have undergone chemical alteration by the high temperature. this feature is of considerable importance to the perfume industry; however, the established distillation method is of lower cost than the extraction process.

how to make marijuana oil stovetop and slow cooker methods

marijuana oil — aka canna-oil, or weed oil to use a more slacker term, is a staple of many cannabis recipes. since thc, the psychoactive component in marijuana, is fat soluble, edible oils make ideal ways to bond it to food. likewise marijuana oils are the backbone of many medicated foods.

oil extraction methods for various oil seed

oil extraction methods. one of the latest oil extraction methods is through chemical extraction, making the use of solvent extracts that creates higher yields and is faster and cheap. the best solvent is the petroleum derived hexane. well this method is used for the most new industrial oil like corn oils and soybean.

the process of extracting cbd from hemp hemp oil talk

the process of extracting cbd from hemp. cannabidiol is the highly popular cannabinoid compound found in cannabis sativa; it typically becomes extracted from industrial hemp that contains less than 0.3% tetrahydrocannabinol meaning it won’t make you high.cbd molecules communicate with the network of cannabinoid receptors spread throughout the body called the endocannabinoid system (ecs).

the effects of different extraction methods on antioxidant

the nigella sativa l. popularly referred to as black seeds are widely used as a form of traditional nutrition and medicine. n. sativa seeds were used for the extraction of their oil by way of supercritical fluid extraction (sfe) and cold press (cp) to determine the physicochemical properties, antioxidant activity, and thermal behavior. the gc-ms results showed the primary constituents in the.