palm oil refinery palm oil processing machine edible oil machine

- Applicable Industries:Farms, Restaurant

- After-sales Service:Field maintenance and repair service

- Dimension (L*W*H):1150*1200*1550mm

- Production capacity:10-150t/d

- Voltage:440V

- Weight:1023kg

- Power:37~45kw

- Advantage:Multifunctional

- Raw material range:almond,sesame,hemp seed

- Transport Package: Container

- Function:Making Edible Oil

palm oil processing machine,edible oil machine plant,palm

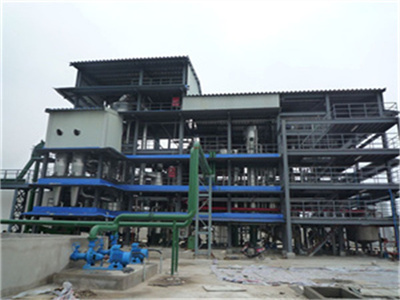

we company mainly produced palm oil processing machine,palm oil refing machine,edible oil pressing machine,which is a professional and best palm oil mill plant manufacturer in china.we can provide palm oil pressing machine, small and large scale palm oil processing plant, automatic palm oil mill plant, palm oil refinery machine and fractionation plant.

palm oil processing machine manufacturer supplier

because of cooking, sterilizing, threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. has been dedicated to the research and development of large, medium-sized and small -sized palm oil processing machine and a variety of edible oil extraction machine for years.

palm oil refinery_palm oil processing machine,edible oil

basing on the traditional palm oil refining technology, our company has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality. moreover, a series of advanced technology and equipment are used, such as super wet degumming, bleaching earth automatic metering, negative press decoloring.

professional palm oil processing machine, palm oil

besides palm oil and palm kernel oil, our palm oil / palm kernel oil refining machine also can be used to refine other crude edible oil, such as soybean oil, peanut oil, cottonseed oil, rapeseed oil, sunflower oil, rice bran oil, mustard oil, and so on.

palm oil refining processing machinery find edible oil

process flow chart: crude palm oil (cpo) is mainly further processed into edible oil for food purpose. to meet the international industry’s standards for edible oil, the crude palm oil produced by oil mill should be refined in palm oil refinery plan t. palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

about us_palm oil processing machine,edible oil machine

grade 1 oil refining machinery won gold medal on the national exhibition of inventions, and mini high-class cooking oil refining unit won gold medal on china fair of inventions and new technologies. as we all know, henan huatai cereals and oils machinery co.,ltd has developed into the biggest manufacture base of grain and oil machinery in china.

small large palm oil processing machine price

palm kernel oil solvent extraction plant is suitable for large palm kernel oil mill with high production capacity. however, for small scale operations, the solvent extraction process is sufficient as an alternative to high production capacity plants. however, this process is not recommended for small scale operations.

how to refine palm oil to vegetable oilch

1. batch type palm oil refining machine. batch type palm oil refining machine is often with the input capacity of 1-10 tpd and uses chemical palm oil refining method. there are one reaction tanks for each step in palm oil refining process, through adding something to remove the impurities out.

edible oil refinery plant manufacturer supplies oil

edible oil refinery plant and edible oil refining process. edible oil refining technology used in edible oil refinery plant is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

palm oil mill machine_palm oil processing machine,edible

1.palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. palm oil mil bunch reception. 2.palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of the fruit, it is.

palm kernel oil extraction machine_palm oil processing machine

palm kernel oil extraction machine palm kernel oil pressing machine ,the machines for extracting palm fruit oil and palm kernel oil are completely different. therefore, if you want to obtain all the oil in palm fruit, there will be two production lines, palm fruit oil production line and palm kernel oil production line.

continuous palm oil physical refining process flow chart

continuous palm oil physical refining process flow chart. this continuous palm oil physical refining process flow chart is based on our engineers&039; designing palm oil physical refining technology, which is for 100tpd continuous palm oil refinery plant project.it is different from other oil refining process, such as soybean oil refining process, sunflower oil refining process, etc.

palm oil refining processing plant palm oil refinery plant

the crude palm oil comes out as yellow red or dark yellow in color and the taste of the crude palm oil is sweat. before going on refining / purifying process of palm oil goyum would like to give brief introduction about processing of fresh fruit bunches (ffb) of palm which includes the harvesting of the palm fruit from the trees, the threshing.

oil refining palm oil mill machine leading manufacturers

small scale oil refinery plant. type: crude oil refinery plant processing capacity: 1 ~ 5t / d processing material: palm oil,palm kernel oil, peanut oil, rapeseed oil, cottonseed oil, sunflower oil, corn germ oil, animal oil etc. small scale oil refining plant introduction: our small scale oil refinery plant are great choice for small capacity oil refinery machine.the

vegetable oil extraction machine manufacturer supplies

vegetable oil extraction machine manufacturer supplies high quality mature technology cooking oil processing machine and edible oil refinery plant with factory price,which can produce soybean oil, sunflower oil, groundnut oil, palm oil, etc.

how to calculate the loss of refined edible oilch

these four parts are the main causes that lead to loss of refined edible oil. but in the commissioning process of edible oil refinery machine, the loss of refined edible oil can low down to the least. the engineers of henan doing company have rich experience in installion and commissioning of edible oil refinery machine.

palm kernel oil processing machine/sunflower oil extaction

palm kernel oil processing machine/sunflower oil extaction machine/ oil refinery machine for crude edible oil , find complete details about palm kernel oil processing machine/sunflower oil extaction machine/ oil refinery machine for crude edible oil,edible oil refinery plant,crude oil refinery plant,small scale oil refinery from oil pressers supplier or manufacturer-zhengzhou gashili machinery.

best palm oil processing machine images in 2020 with good price

500kg/h palm oil processing machine is used to extract crude palm oil from palm fruit and get high oil yield palm oil. palm oil processing machine, also called as palm oil extraction machine, are utilized in palm oil mill or palm oil pressing plant for effective palm oi production. the design and technology of palm oil mill plant are very important for its smooth operation and further.

edible oil refinery plant and edible oil refining process

our company's product range includes a wide range of edible oil refining equipment and vegetable oil refining equipment, which can be divided into 1-20tpd intermittent edible oil refining equipment, 10-50tpd semi-continuous edible oil refining equipment and 30-1000tpd fully continuous edible oil refining equipment by type.

palm kernel oil refining process/crude oil refining machine

manufacturing palm kernel oil refining process/crude oil refining machine,the purpose of palm kernel oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces.