pakistan crude oil refinery equipment buy crude oil refinery

- Applicable Industries:Food & Beverage Factory, Food Shop

- After-sales Service:24h Service Online

- Dimension (L*W*H):1750*1700*1550mm

- Production capacity:25t-30t/D

- Voltage:110V/220V/380V

- Weight:780kg

- Power:18.5-22kw

- Advantage:High Productivity

- Raw material range:tea seed,sunflower,soybean

- Transport Package: Wooden Case

- Automatic:Automatic Grade

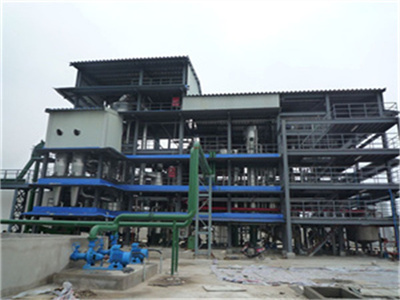

crude oil refining plant process

crude oil refining . we have extensive experience in the design and manufacture of refining equipment and the construction and operation of crude edible oil refinery machine. ppe can build a modular refinery in our shops and it can be easily shipped to your location anywhere in the world.

oil refiners: refiners stare at inventory losses on crude

new delhi: a crude oil crash would cause inventory losses to refiners while cutting cost of their borrowings and fuel consumption, industry executives and analysts said. shares of reliance industries andn oil, expected to have higher inventory losses, fell while those of hpcl and bpcl, with expected lower inventory losses, soared on monday..

oil refinery process units, refinery equipment list

oil refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as edible oil refinery machine) to transform crude oil into useful products such as liquefied petroleum gas (lpg), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

2024 best selling hot sale mini crude cooking oil sunflower/peanut oil

introduction of mini crude cooking oil sunflower/peanut oil refinery machine mini edible oil refining plant: a general term for a series of processes for removing solid impurities, free fatty acids, phospholipids, gums, waxes, pigments, odors, etc. contained in vegetable oils.

dangote refinery takes delivery of crude oil distilling

a piece of very vital equipment that will process crude oil for dangote petroleum refinery and petrochemicals company has just arrived lekki, the group’s refinery site in lagos, punch says. the details: the equipment is a crude distillation column capable of delivering 650,000 barrels per stream day (bpsd).

crude oil refinery plant/equipment, oil refining machine

the description of the bzj series batching used oil refining plants mainly includes bzj-6 and bzj-10 models. the daily capacity of the batch waste oil refining equipment is 6t/d and 10 t/d respectively. the crude oil refinery machine can be operated in normal press and vacuum condition.

nigeria: dangote refinery receives world's largest crude

head, maritime and ports infrastructure of dangote, capt. rajen sachar, told journalists during the arrival of the facility in lagos that the equipment is the biggest single-train facility used for...

light vs heavy crude oil petroleum refinery equipment

light crude oil receives a higher price than heavy crude oil on commodity markets because it produces a higher percentage of gasoline and diesel fuel when converted into products by an oil refinery. heavy crude oil has more negative impact on the environment than its light counterpart since its refinement requires the use of more advanced.

refinery equipment of texas, llc

refinery equipment of texas typical 1000 / 3000 / 6000 bpd process flow diagram technical operation typically, cold crude oil from off-site storage is received at the topping plant battery limits and pumped by the crude charge pump on flow control. the crude oil exchanges heat with the atmospheric tower product streams.

refinery equipment services oil gas baker hughes

our chemical treatment programs and services reduce refinery feedstock cost and improve feedstock selection flexibility. our differential chemical technologies and application experience with opportunity crude oil allows you to process higher rates of these feedstocks.

the crude oil distillation unit petroleum refinery

the crude oil distillation unit (cdu) is the first processing unit in virtually all petroleum refineries.the cdu distills the incoming crude oil into various fractions of different boiling ranges, each of which are then processed further in the other refinery processing units.

small edible oil coconut meat oil refinery plant

an oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need.

4 oil refiners to buy when crude is low thestreet

4 oil refiners to buy when crude is low.people also tend to buy more gas when oil is low, so there's more demand for the refineries.engages in refining, marketing, retailing, the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.

an investor's guide to refinery stocks the motley fool

the crack spread is an oil industry term that refers to the difference in price between where a refinery buys raw crude oil and sells the petroleum products it makes from this oil. the spread is.

oil refinery processes

crude oil distillation is more complicated than product distillation, in part because crude oils contain water, salts, and suspended solids. step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units.

manufacturer, supplier of small scale sunflower oil refining

the small scale sunflower oil refining machine has all the advantages of large and medium-sized edible oil refining machine. what's more, small scale sunflower oil refining machine widely used to refine various kinds of crude edible oil, such as soybean oil, peanut oil, cottonseed oil, rapeseed oil, mustards oil, palm oil, palm kernel oil etc.

refinery margin tracker: global margins strengthen

refining margins strengthened as refined product price declines were outpaced by falling crude prices. refined product demand in china was stymied by declines in transport activity, creating product builds in regional markets and redirecting crude flows.

pre-treatment of heavy crude oils for refining intechopen

the economic unattractiveness of heavy crude oils in the global oil market scene is fast changing due to the looming scarcity of light oils. there are huge reserves of heavy oils to which refiners are being reluctantly attracted. the fully developed conventionally available refineries are, however, incapable of processing these heavy crudes without some major modifications of both process the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.

best oil refining/marketing stocks us news best stocks

the oil refining/marketing sector includes companies that refine and sell crude oil. companies that refine oil manufacture it into a number of petroleum products, including gasoline, jet fuel the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.

the process of crude oil refining eme 801: energy

presenter: for crude oil to be used effectively by modern industry, it has to be separated into its component parts and have impurities like sulfur removed. the most common method of refining crude is the process of fractional distillation. this involves heating crude oil to about 350 degrees celsius, to turn it into a mixture of gases.