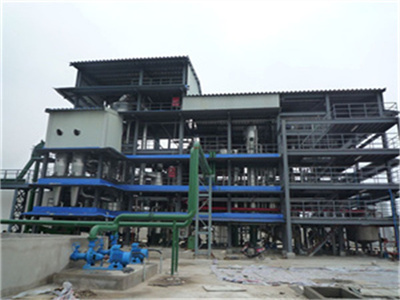

nepal chemical and physical refining crude palm oil refinery plant

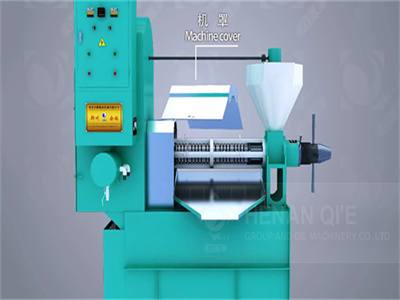

- Applicable Industries:Food & Beverage Factory, Food Shop

- After-sales Service:commissioning and training

- Dimension (L*W*H):2019*1291*1855mm

- Production capacity:1-30t/d

- Voltage:380V/50HZ/Triple phase

- Weight:370kg

- Power:18.5-22kw

- Advantage:High Efficiency

- Raw material range:palm,castor,rape seed,black seed,rape seed

- Transport Package: Export Fumigation-Free Wooden Box

- Origin:Zhengzhou, China

physical and chemical process in palm oil refining plant

palm oil physical refining process. oil physical refining process, also called as oil steam refining. during the degumming section in the palm oil milling plant, the gum will be removed from palm oil by utilizing phosphoric acid or citric acid. next to bleaching section, the coloring matter and other metal ions will be absorbed or removed.

palm oil refining processing plant palm oil refinery plant

refining of crude vegetable oil is done by two methods: physical refining and chemical refining. during refining of crude palm oil, ffa are removed in order to achieve the ffa content of up to 0.1 % max. physical refining generally has a lower environmental effect than chemical refining.

turnkey project of palm oil refinery plant physical refining machine

crude palm oil (cpo) is mainly further processed into edible oil for food purpose. to meet the international industry’s standards for edible oil, the crude palm oil produced by oil mill should be refined in palm oil refinery plant.palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

introduction of palm oil refining process physical

palm oil refining is adopted to deep process crude palm oil by removing impurities like gum, acid, pigment and bad smell. palm oil refining can be divided into chemical refining and physical refining.we can provide different methods of refining according to the acid value of your palm crude oil.

palm oil refining

there are two refining methods for the palm oil refining in the palm oil refinery plant. they are physical refining and chemical refining. physical refining means removing gum in palm oil during process of degumming in special method and removing ffa in process of deodorizing by steam.

manufacture palm oil refining methods,low cost price

no matter palm oil physical refining or palm oil chemical refining all refers to remove phospholipids, ffa, pigment, off-flavor and other impurities in the palm oil. palm oil refinery plant aims to improve palm oil flavor, prolongs storage time, and produce high quality palm oil.

palm oil refinery process physical chemical oil machine

physical palm oil refinery plant is featured of high efficiency, simple production process and low effluent load. chemical refining of palm oil; in the chemical refining process, the ffa is removed by neutralisation with caustic soda (sodium hydroxide). this chemical reaction produces neutralised cpo and a soap stock.

chemical refining and physical refining of vegetable oil

physical refining. apart from chemical refining, physical refining is another method that used for edible oil refining. through this method, the free fatty acids are removed during the process of distillation, which is one stage of deodorizing. the crude oil should be thoroughly degummed to come up with effective results.

what is the difference between physical refining

same purpose as physical refining of edible oil, the deodorization section mainly used to remove off-flavors and odours in crude edible oil by the help of steam distillation. 20tpd palm oil chemical refining project case. what is the features of edible oil chemical refining>

oil refining oil chemists&039; society

consequently, to reach the maximum oil quality all the steps of the refining process should be carried out with the minimum losses of desirable compounds. the major steps involved and the main components removed are shown in table 1. as can be observed, alkali (or chemical) and physical refining are the standard processes used.

refining of palm oil: part 2

in part 2, i explained the various stages involved in physical and chemical refining of crude palm oil and differences between the two refining methods. presented by professor abd karim alias.

palm oil refinery_palm oil processing machine,edible oil

basing on the traditional palm oil refining technology, our company has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality. moreover, a series of advanced technology and equipment are used, such as super wet degumming, bleaching earth automatic metering, negative press decoloring.

chemical degumming oil chemists&039; society

the advantages of top are an increase in oil yield from 0.6 to 1 % for top + physical refining compared to chemical refining, and elimination of pollution problems associated with soap stock splitting. the efficiency depends appreciably on the agitation and the type of crude oil.

continuous palm oil refinery plant working process 3d

the continuous palm oil refinery plant adopts physical refining method. in this video, degumming and decolorization of palm oil are showed step by step. song

chemical refining of crude palm oil linkedin slideshare

chemical refining of crude palm oil 1. explain the chemical refiningprocess. describe exactly whatis/are removed in each step ofthe refining processreference :process design in degumming and bleaching ofpalm oil by prof.madya dr. noor azian morad,prof.madya mustafa kamal abd aziz amp rohani binti mohd zin of clear, utmclear : centre of lipids.

small edible oil coconut meat oil refinery plant

an oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need.

vegetable oil refinery plant palm oil refining plant oem

the palm oil physical or palm oil refining plant processing plant has the advantage of eliminating the caustic refining and soap stock acidulation process. the pre-fatty acid content of crude palm oil can easily be removed in a steam refining deodorizer in the physical refining plant, however, any phosphates present in the feedstock will char at the high temperature used for steam refining.

set up a palm oil refinery plant with low cost, for sale

low cost of palm oil refining equipment. dry physical palm oil refining method don't have neutralization process and washing process, so related machines are not required. no waste water and don't need wastewater treatment plant. doing company has been specialized in palm oil refinery plant for decades.

palm oil refinery wastes treatment

abstract--effluent from the refining of crude palm oil was subjected to physical-chemical and biological treatment. an inclined corrugated parallel plates oil separator spaced at 25 mm was used with hydraulic

crude palm oil refinery plant palm oil processing plant

refining of crude vegetable oil is done by two methods: physical refining and chemical refining. during refining of crude palm oil, ffa are removed in order to achieve the ffa content of up to 0.1 % max. physical refining generally has a lower environmental effect than chemical refining.