namibia rotocel extractor in cooking oil solvent extraction plant

- Applicable Industries:Food and Beverage Shops

- After-sales Service:Video Technical Support/Online support

- Dimension (L*W*H):1680*1050*960mm

- Production capacity:370-500kg/h

- Voltage:440V

- Weight:2600kg

- Power:2.2kw

- Advantage:Simple Operation

- Raw material range:sunflower,black seed,pepper seed,peanut

- Transport Package: Export Wooden Crates

- Press type:Hydraulic Pressure

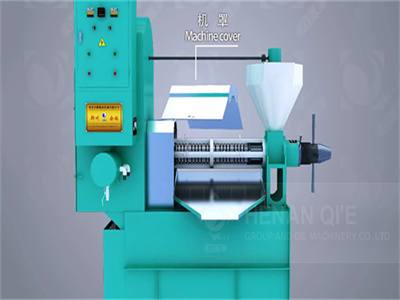

rotocel extractor for cooking oil solvent extraction plant

if you wanna to get more details about rotocel extractor for cooking oil solvent extraction plant you can send e-mail. you can consult our professional engineer and specialized sales team with leave a message in below form.we will contact with you asap.you also can visit our factory in henan,china.

the application of rotocel extractor in cooking oil

the cost of the rotocel extractor is lowest among these three kinds of solvent extractors, but it is not suitable for the big capacity cooking oil solvent extraction workshop, more than 500tons/day. besides, because rotocel extractor has smaller size than loop type solvent extractor, it needs smaller workshop, which makes the cost of building.

rotocel extractor in cooking oil solvent extraction plant

rotocel extractor in cooking oil solvent extraction plant date:2016-03-14 12:01:32 / cooking oil solvent extraction plant / give me the price / leave a message. in cooking oil solvent extraction plant, the first machine used is extractor. there are two main kinds of extractor of doing company, rotocel extractor and loop-type extractor. this.

rotocel extractor for solvent extraction oil plant

rotocel extractor . is a continuous oil extraction equipment and widely suitable for all kinds of vegetable oil extraction. its main characteristic is high bed of oilseeds, mixed oil concentration is high, simple structure, convenient operation and maintenance.

rotocel extractor_cooking oil solvent extraction plant

rotocel extractor date:2016-11-09 13:53:02 / cooking oil solvent extraction plant / give me the price / leave a message cooking oil extractor mainly includes rotocel extractor,loop type extractor and towline extractor.according to different raw material , we adopt different machine type,

10-300 tpd solvent extraction plant (rotocel extractor)

the advantages of rotocel extractor. the rotocel extractor we designed, is of strong leaching performance, to oil bearing material's (of 25-35% oil content) puffing material or pre-pressed cake, can get the oil residual content below 1%. extraction is a chemistry way to extract oil from soybean .

oil extractor- edible oil extraction machine

edible oil extraction is using solvent to extract oil inside oil extractor. here we talk about rotocel oil extractor. rotocel oil extractor is one of most important edible oil extraction machine , is comprised by cylinder-shaped case , rotor with several lattices , and drive device etc.rotocel oil extractor has three types : movable (false.

rotocel extractor for solvent extraction oil plant

loose bottom rotocel extractor is widely used in domestic oil processing plant in the 1980s. after the 1990s, fixed bottom rotocel extractor became popular, while the loose bottom rotocel extractor was gradually being phased out. fixed bottom rotocel extractor has the features of simple structure, easy manufacture, low power consumption, smooth.

china rotocel extractor for solvent extraction oil plant

solvent extraction oil plant: rotocel extractor 1. general description rotocel extractor is the extractor with a cylindrical shell, a rotor and a drive device inside, with simple structure, advanced technology, high safety, automatic control, smooth operation, less failure, low power consumption.

rotocel sld-topoilsolution.com

rotocel. solvent extraction and stripping is the core step of the entire process. generally, rotocel is widely used in the extraction plant with less than 600tpd capacity. according to different raw materials,solvent extraction generally includes the following sections: (1) feeding scraper (2)rotocel (3) d.t.d.c (4) evaporation condensation. 1.

solvent extraction method for edible oil processing machine

solvent extraction is a chemical oil extraction method to process oil out from vegetables, oilseeds and nuts by solvent, and hexane is the preferred choice. industrial oil processing for the edible oil generally involves the solvent extraction step which may or may not be preceded by pressing.

edible oil extractor manufacturer, rotocel extractor for sale

rotocel extractor is the most widely used edible oil extraction equipment, suitable for small and medium oil extraction plant. rotocel extractor is suitable for the oil extraction of peanut, rapeseed, cottonseed, sunflower seed, sesame, corn germ, avocado, flax seed, castor seed, soybean, rice bran, safflower seed, palm fruit cake, palm.

buy solvent extraction oil plant: rotocel extractor

solvent extraction oil plant: rotocel extractor. rotocel extractor is the extractor with a cylindrical shell, a rotor and a drive device inside, with simple structure, advanced technology, high safety, automatic control, smooth operation, less failure, low power consumption.

rotocel extractor oil-press-machine.org

features of our rotocel extractor: 1.adopt stainless fixed plate grid,add the crosswise plate grid,prevent thicken miscella oil flow back to material place,keep the solvent extraction effect; 2.the rotocel extractor adopts rack driven,special rotor balance design,low rotating speed,lower power,working stably without noise,low maintenance cost;

vegetable oil extraction machine for sale

there are three types of machines used in vegetable oil solvent extraction plants; leaching tanks used for processing 10-20 tons of oil bearing material; rotocel extractor used in processing 30-300 tons of material; loop type extractor used for processing oil bearing materials of 500 tons and above

rotocel extractor

solvent extraction machine, rice bran extraction machine, soybean extraction machine.

cottonseed oil extraction plant edible oil expeller

oil extraction is using the organic solvent to extract oil from the pre-pressed cake inside the oil extractor. multiple oil extractors such as loop type extractor, rotocel extractor and towline extractor can be used for the cottonseed oil extraction plant. after oil extraction, miscella and the solvent containing wet meal are obtained.

extractors an overview sciencedirect topics

extractors are either single-stage or multistage batch tanks or continuous extractors. a summary of the requirements for batch and continuous solvent extraction of oil is shown in table 3.4 and details of solvent extraction of cooking oil are given by anderson (2011).in batch extractors, closed tanks are fitted with a mesh base to support the solid particles of food.

oil solvent extraction plant buleoil.com

1) solvent pumps: continuously spray solvent to the rotocel extractor. 2) rotocel extractor: spray and soak the pre-pressed cake with solvent so that oil can be dissolved in solvent (form miscella). after processing,you can get wet meal and miscella (mixed oil). 3) dtdc: used to separate the solvent from the wet meal.

desmet ballestra reflex

contact time is the single most important factor for the efficient solvent extraction of vegetable oils. to maximize contact time, the reflex’s sealed divider design enables the oilseed material to be completely surrounded with miscella from the time it enters the extractor until the extraction cycle is complete.