namibia animal fats for biodiesel production edible oil expeller

- Applicable Industries:Manufacturing Plant

- After-sales Service:Service Machinery Overseas

- Dimension (L*W*H):730*810*1200mm

- Production capacity:120 tpd

- Voltage:440V

- Weight:1980kg

- Power:55+11+4kw

- Advantage:Low price

- Raw material range:grape pip,grape pip,corn germ,rape seed,grape pip

- Transport Package: Export Fumigation-Free Wooden Box

- Oil rate:45%-60%

animal fats for biodiesel production edible oil expeller

b100 (pure biodiesel) made from animal fat should only be used in a very warm climate. however, animal fat biodiesel can be blended with petro-diesel. at lower blends such as b5 (a blend of 5% biodiesel with 95% petro-diesel), the high cloud point of the animal fat biodiesel does not have much effect on the cloud point of the blend.

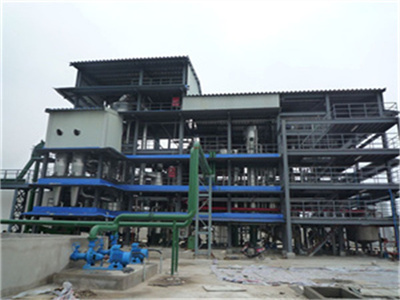

biodiesel production edible oil expeller machinery

commonly used feedstocks for the production of biodiesel include soybean, rapeseed/canola, used (waste) vegetable oils, and tallow/lard (animal fat). mustard biodiesel is being studied at the university of idaho, and montana state university is conducting research on camelina for biodiesel production.safflower, sunflowers, corn, and even

biodiesel technology from waste oil edible oil expeller

waste oil mentions to oil during production of edible oil and meat processing. it includes acid oil, food oil, cooking oil, vegetable oil and animal store expired fat. the biodiesel technology can perfectly convert vegetable or animal waste oil into biodiesel through a series of processing flows. acidification oil

biodiesel process edible oil expeller machinery

biodiesel is an alternative diesel fuel consisting of fatty acid alkyl monoesters from vegetable oils or animal fats. at present, most biodiesel is produced from soybean oil, methanol and an alkaline catalyst (cholinesterase). however, most of the cheap oils that are not easily digested by human body can be converted into biodiesel.

animal fats for biodiesel production farm energy

animal fats are attractive feedstocks for biodiesel because their cost is substantially lower than the cost of vegetable oil. this is partly because the market for animal fat is much more limited than the market for vegetable oil, since much of the animal fat produced in the u.s. is not considered edible by humans.

advantages of biodiesel technology edible oil expeller

biodiesel, also known as fatty acid methyl esters (fatty acid ester) uses the fruit of plants, seeds, vegetable oils or animal fat milk ducts, waste cooking oil and others as materials. it is obtained by lactide reaction (transesterification reaction) with alcohols (methanol, ethanol). german engineer dr. rudolf diesel (1858-1913) first mentioned the concept of biodiesel. […]

biodiesel process edible oil expeller machinery

biodiesel is an alternative diesel fuel consisting of fatty acid alkyl monoesters from vegetable oils or animal fats. at present, most biodiesel is produced from soybean oil, methanol and an alkaline catalyst (cholinesterase). however, most of the cheap oils that are not easily digested by human body can be converted into biodiesel.

biodiesel production line palm oil expeller

biodiesel production from waste oil press equipment manufacturers and suppliers htoil machine. biodiesel is an alternative fuel for diesel engines. patent invention production of biodiesel production is focusing on chemically processing and recovery technology from waste vegetal oil or animal oil or fat in urban catering pigwash.

animal fats oil chemists&039; society

compared to the production of biodiesel from vegetable oil, production from animal fat is more challenging and expensive. this is linked to typical constituents like salts, phosphorus, sulphur, and plastics, which cannot be totally removed in a prior step [18].

production of biodiesel flax seed oil press extraction test

comparison of oil extraction methods, energy analysis. jul 01, 2013· in recent years, the commercial potential of oil extraction and biodiesel production derived from vegetable seed is being realized. the process energy input requirements are important factors in oil extraction and biodiesel production.

biodiesel production from different non-edible oils

biodiesel production from different non-edible oils containing high free fatty acid . m.k. mohanty amp s. mishra . abstract: demand of fuels is increasing gradually. it is likely to increase the import dependence for oil which is about 70 per cent. it is also well known that the petroleum resources are limited which are non-renewable in

biodiesel technologies

non edible oils were mostly wildly grown or cultivated in very nominal quantities for other purposes. with the beginning of the biodiesel era, there is a tremendous thrust all over the globe in cultivating non edible oil seeds particularly jatropha curcas which has been identified as the most commercially viable oil seed for biodiesel industry.

animal fats oil chemists&039; society

compared to the production of biodiesel from vegetable oil, production from animal fat is more challenging and expensive. this is linked to typical constituents like salts, phosphorus, sulphur, and plastics, which cannot be totally removed in a prior step [18].

biodiesel production line palm oil expeller

biodiesel production from waste oil press equipment manufacturers and suppliers htoil machine. biodiesel is an alternative fuel for diesel engines. patent invention production of biodiesel production is focusing on chemically processing and recovery technology from waste vegetal oil or animal oil or fat in urban catering pigwash.

production of biodiesel flax seed oil press extraction test

comparison of oil extraction methods, energy analysis. jul 01, 2013· in recent years, the commercial potential of oil extraction and biodiesel production derived from vegetable seed is being realized. the process energy input requirements are important factors in oil extraction and biodiesel production.

biodiesel technologies

non edible oils were mostly wildly grown or cultivated in very nominal quantities for other purposes. with the beginning of the biodiesel era, there is a tremendous thrust all over the globe in cultivating non edible oil seeds particularly jatropha curcas which has been identified as the most commercially viable oil seed for biodiesel industry.

chapter 2 introduction to biodiesel production

etable oils, and also animal fats. methanol is the most frequently used alcohol although ethanol can also be used. since cost is the main concern in biodiesel production and trading (mainly due to oil prices), the use of non-edible vegetable oils has been studied for several years with good results. 8 2 introduction to biodiesel production

biodiesel production from different non-edible oils

biodiesel production from different non-edible oils containing high free fatty acid . m.k. mohanty amp s. mishra . abstract: demand of fuels is increasing gradually. it is likely to increase the import dependence for oil which is about 70 per cent. it is also well known that the petroleum resources are limited which are non-renewable in

biodiesel technologies

non edible oils were mostly wildly grown or cultivated in very nominal quantities for other purposes. with the beginning of the biodiesel era, there is a tremendous thrust all over the globe in cultivating non edible oil seeds particularly jatropha curcas which has been identified as the most commercially viable oil seed for biodiesel industry.

chapter 2 introduction to biodiesel production

etable oils, and also animal fats. methanol is the most frequently used alcohol although ethanol can also be used. since cost is the main concern in biodiesel production and trading (mainly due to oil prices), the use of non-edible vegetable oils has been studied for several years with good results. 8 2 introduction to biodiesel production

biodiesel production from different non-edible oils

biodiesel production from different non-edible oils containing high free fatty acid . m.k. mohanty amp s. mishra . abstract: demand of fuels is increasing gradually. it is likely to increase the import dependence for oil which is about 70 per cent. it is also well known that the petroleum resources are limited which are non-renewable in

biodiesel production plant, biodiesel production equipment

biodiesel is typically produced through the reaction of a vegetable oil or animal fat with methanol in the presence of a catalyst to yield glycerine and biodiesel (chemically called methyl esters). biodiesel is an alternative fuel, which can be used in neat form, or blended with petroleum diesel for use in compression ignition (diesel) engines.

biodiesel production from karanja oil and its use in diesel

however, biodiesel production from edible oils and animal fats may affect the food material., edible oil is very dear then non-edible oil. produces 9.3% of world's total oilseeds even though, it has to import edible oil . consumes 16.6 mt of edible oil every year.

a systematic evaluation of the mechanical extraction

among the different alternative raw materials for biodiesel production, animal rendering fats, non-edible vegetable oils, and waste oils (e.g. used cooking oil, trap greases) have been extensively investigated because they are widely available, cannot be used for food or feed production, and in some cases their nutritional value has been