mumbai cooking grape seed sunflower oil refining process

- Applicable Industries:Food and Beverage Shops

- After-sales Service:Online Service

- Dimension (L*W*H):400*500*850mm

- Production capacity:10-15tpd

- Voltage:440V

- Weight:950kg

- Power:22kw (4 Poles)

- Advantage:High quality

- Raw material range:pine nut,camellia seed,corn germ,linseed,rice bran

- Transport Package: Wood

- Color:Customer's Request

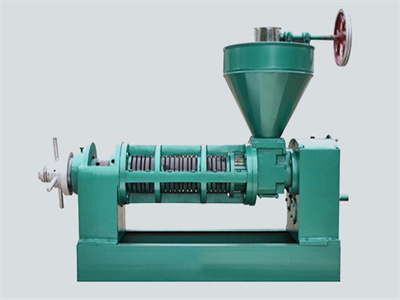

batch type crude cooking oil refining production machine

batch type crude cooking oil refining production machine small scale edible oil refining machine , find complete details about batch type crude cooking oil refining production machine small scale edible oil refining machine,palm oil refinery,refined sunflower oil from,palm oil refinery tanks from oil pressers supplier or manufacturer-henan doing environmental protection.

sunflower seeds oil refining machine crude oil

cooking oil production line are mounted units category a few brands pt international brand you will find in our inventory. find sunflower seeds oil refining machine crude oil refining machine to see what's in pt international manufacturer name stock! oil expeller, oil press and oil refinery machine supplier

automatic mini deodorizer oil press equipment cooking crude palm

cooking oil refinery batch type vegetable oil refinery in batch type vegetable oil refinery plant, processes are carried out by deodorizing, bleaching and neutralizing of certain quantity of oil. as the batch process is easy to operate and low in cost unfiltered matter and various impurities from seed like coloured, mucilage and gums are.

automatic sunflower oil machine for extraction

automatic sunflower oil machine for extraction and refinery . automatic sunflower oil machine is used to process sunflower seeds to edible oil. we have two methods to process sunflower to oil, one is mechanical press method , the other is solvent extraction method. we have three kinds production line:

sunflower oil cooking oil and edible oil manufacturers

this is the refined, cooking oil that reaches you, loaded with nutrition. the perception today is that refining can make food products and oils lose vital nutrients. this however does not hold true for sunflower oil. one of the defining characteristic of sunflower oil is its high smoking point. this basically means that vilina.

extraction of grape seed oil and refining process

grape seed oil contains a large number of fat-soluble vitamins a, d, e and k, content reach ve35.95, vk29.41, va8.06, vd4.03, vp0.94 mg / 100 grams of oil, a tablespoon of grape seed oil is equivalent to all the vitamin e a person need one day. characteristics of grape seed oil

oil seeds pressing process of cooking oil production line

let us suppose the oil raw material is sunflower seeds, you can see the whole production line,the small scale oil pressing line is easy to operate, install and commission. the small scale oil pressing line requires little initial investment and a minimal workspace, but performs all functions necessary for edible oil production.share this post

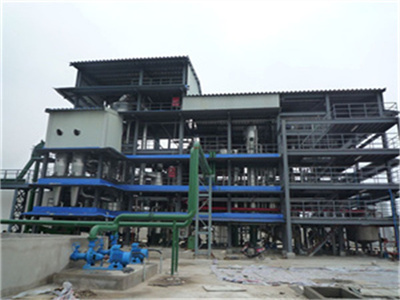

sunflower oil processing plant cooking oil mill machinery

the processing flow chart of sunflower oil solvent extraction plant. 3. sunflower oil refining section: sunflower oil refinery plant is to remove harmful impuries and useless substance, such as protein, phospholipid, pigment, moisture, wax and other impurities. and then the refined sunflower oil can reach the standard of food and storage.

sunflower oil production line seed oil press

currently, the sunflower oil sold on the market is mostly produced by de-shelled pre-squeezing and leaching process. de-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved.

deodorization process, oil deodorization ... oil refinery

each crude oil responds differently to the deodorization parameters. soyabean oil will differ from cottonseed oil. sunflower oil will differ from palm oil. so is with groundnut oil or rapeseed oil or coconut oil. the thermal effect of the deodorizer will destroy the oil flavor and the heat sensitive color pigments.

processes involved in sunflower oil production

sunflower seed oil production does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. a volatile hydrocarbon like hexane is used as a solvent to extract the oil. 6 processes of sunflower oil production

sunflower oil refining process vegetable oil refining

the kernel makes up about 70 percent of the seed with an content of oil about 55 percent. in order to obtain high-quality sunflower oil, the crude oil pressed by kmec oil pressing plant must have the waxes as well as gums removed by using our sunflower oil refining process. in the finished product, these waxes would crystallize at low.

sunflower oil extraction process, methods with low cost

sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. de-hulling is completed when the seed has a moisture content of 5% after cleaning.

25kg batch vegetable oil deodorizer ready for shipment

25kg batch vegetable oil deodorizer stainless steel. below is some pictures we take during the equipment manufacturing process. stainless steel mini oil deodorizer. customized digital display cabinet for oil deodorization equipment . 25kg oil deodorizer packed for shipment to america. oil deodorization process

grape seed oil — is it a healthy cooking oil

grape seed oil is processed from grape seeds, which are an abundant byproduct of winemaking. it’s relatively high in vitamin e and phenolic antioxidants, as well as a rich source of omega-6 fatty.

basics oil refining

seed oil milling desolventizer/ toaster day bin de-hulling for sunflower oil filter crude oil truck scale oil seed vessel batch scale quality control impurities oil content moisture press 15 20 % oil meal storage steam hexane extractor distillation condensation electro magnet cooker 80 –100 ˚c seed preparation warehouse or silo’s pressed.

sunflower oil refinery plant edible oil extraction machine

sunflower oil refinery plant for sale, sunflower oil refinery plant is one of the most popular sunflower oil processing machine. sunflower oil refinery plant mainly used to refine crude sunflower oil to standrd cooking oil. to achieve this goal, sunflower oil refinery plant usually needs t

cooking oils with low smell our everyday life

the refining process peanut oil undergoes removes the proteins that act as allergens in peanut-sensitive people, so they can consume it without the threat of a reaction. corn oil refined corn oil has little to no smell or taste, and it starts smoking at 450 f. corn oil tolerates all forms of cooking and works well in baked goods in which you.

sunflower processing, processing of oil seed and none-oil seed

sunflower seed oil is cold-pressed. the cold-press entails minimal processing to produce a light, flavorful oil suitable for some cooking needs. sunflower oil manufacture involves seeds cleaning, seed de-hulling, seeds grinding, seeds pressing and extracting crude oil, crude oil refining. 1. cleaning

sunflower processing crown iron works

the first step in processing sunflower is to properly prepare the seed for oil removal. the seed is cleaned using magnets to remove metal and screening to remove impurities that can interfere with the process. the seed can be dehulled by cracking and removing the shell or can be sent to pressing with the shell still intact.