lagos palm oil refining sunflower edible oil refining plant

- Applicable Industries:Food & Beverage Factory, Food Shop

- After-sales Service:Field maintenance and repair service

- Dimension (L*W*H):920*480*760mm

- Production capacity:1-30t/d

- Voltage:380V/50HZ/3 phase

- Weight:590kg

- Power:Y315m-6-45kw

- Advantage:Factory price

- Raw material range:baobab seed,rice bran,soybean,rice bran,mustard

- Transport Package: Fumigated Wooden Box or as Customer′s Request

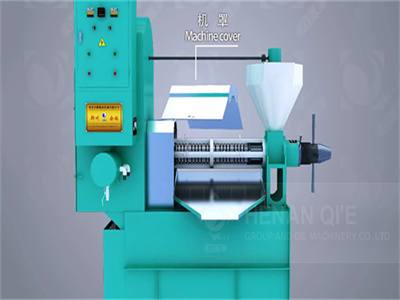

- Type:Industrial cold oil press

edible oil refinery, vegetable oil refinery, cooking oil

edible oil refinery. edible oil refinery from tinytech is a masterpiece for oils fats. we develop uniquely designed economical refinery systems which are suitable and adaptable to majority of the masses as compared to those giant complex ones.

edible oil refinery, vegetable oil refinery, cooking oil

what we serve is equally important to what we offer. with over 25 years of existence in our field, we have gained incredible expertise in providing services in terms of process development, technical evaluation studies, design of plants, oil refinery equipment, improvement and expansion of existing facilities, studies from the point of view of pollution prevention, energy conservation the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.

edible oil refinery machine technology myande group

edible oil refinery technology. the objective of refining is to remove objectionable co-constituents in edible oil with the least possible damage to glycerides and minimal loss of desirable constituents. methods of refining depend on nature and quantity of impurities contained in crude oil, application of rbd oil.

edible oil refinery plant and edible oil refining process

our company's product range includes a wide range of edible oil refining equipment and vegetable oil refining equipment, which can be divided into 1-20tpd intermittent edible oil refining equipment, 10-50tpd semi-continuous edible oil refining equipment and 30-1000tpd fully continuous edible oil refining equipment by type.

vegetable oil refinery plant palm oil refining plant oem

the palm oil physical or palm oil refining plant processing plant has the advantage of eliminating the caustic refining and soap stock acidulation process. the pre-fatty acid content of crude palm oil can easily be removed in a steam refining deodorizer in the physical refining plant, however, any phosphates present in the feedstock will char at the high temperature used for steam refining.

palm oil refining processing plant palm oil refinery plant

if you are planning to set up a palm oil refining plant or oil refinery equipments, you are in the right place! we take the opportunity to introduce goyum screw press, an iso 9001 company, a leading oil mill engineering firm, specialist in vegetable oil extraction and refinery field.

edible oil refinery plant manufacturer supplies oil

edible oil refinery plant and edible oil refining process. edible oil refining technology used in edible oil refinery plant is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

sunflower oil refining processing plant sunflower oil refinery

sunflower oil is very important edible oil these days. sunflower seeds are produced in many countries including, china, romania, united republic of, hungry, france, and etc. goyum is a leading turnkey project manufacturer, supplier and exporter of sunflower oil refining plant from.

high quality edible oil refinery plant manufacturers exporters

edible oil refinery plant manufacturers exporters. muez-hest is a technology development and epc with a large part of our expertise pertaining to edible oil refinery plant manufacturers exporters.. edible oil refinery plant requires precision of machinery while ensuring minimum addition of contaminants and odour producing agents.. muez-hest has worked tirelessly with many customers in.

chemical refining and physical refining of vegetable oil

edible/vegetable oil refining is a step by step process. refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. the entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

supply vegetable oil refinery plant for refining crude

edible oil refinery machine manufacturer supplies vegetable oil refinery plant for refining crude palm oil, soybean oil, sunflower oil, etc, with mature oil refining technology and factory price. vegetable oil extraction machine manufacturer; email:oil machine@doingoil machine.com.

turnkey project of palm oil refinery plant physical refining machine

crude palm oil (cpo) is mainly further processed into edible oil for food purpose. to meet the international industry’s standards for edible oil, the crude palm oil produced by oil mill should be refined in palm oil refinery plant.palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

cooking oil refinery batch type vegetable oil refinery

in batch type vegetable oil refinery plant, processes are carried out by deodorizing, bleaching and neutralizing of certain quantity of oil. as the batch process is easy to operate and low in cost unfiltered matter and various impurities from seed like coloured, mucilage and gums are present in crude oil which is extracted from the expellers of.

tirumalla oil refinery pvt ltd edible oil processing machine

edible/vegetable/cooking oil degumming ... 1-10tpd batch type edible oil refinery plant ,edible oil refinery/ soybean oil refinery/sunflower oil /palm oil refining machine.

what's the application of edible oil refining plant

after oil pressing process or oil solvent extraction process, we get crude oil. but the crude oil can’t flow to supermarket. the crude oil must need processing with edible oil refining plant, especially soybean, cottonseed, rapeseed, palm kernel, etc.

cooking oil refinery plant, vegetable oil refinery plant

cooking oil refinery, vegetable oil refinery, edible oil refinery, edible oil refinery plant, vegetable oil refinery plant, edible oil refining, vegetable oil.

vegetable oil refining plant and machinery, edible oil

peanuts i.e. ground nuts, copra, sunflower seed, palm kernal, canola seed i.e. rape seed or mustards seed yields major oil through screw presses and in majority of the cases the oil obtained can be and is being used directly as edible oil.

basics of alkali refining of vegetable oils

alkali refining: plant design crude oil dosation the capacity of the plant is adjusted by a speed controlled crude oil pump in combination with a massflowmeter. a pre-strainer is installed to protect the pump and following equipment . the oil temperature is adjusted with a heat exchanger by means of steam. dual pre-strainer massflow meter crude.

vegetable oil refining plant,edible oil refinery plant,oil

qie machinery manufacture vegetable oil refining plant,edible oil refinery plant,oil refining machine,cooking oil refining machine,palm oil refinery machine with 60 years experience,any oil refining process information need,please leave us a message

physical and chemical process in palm oil refining plant

palm oil physical refining process. oil physical refining process, also called as oil steam refining. during the degumming section in the palm oil milling plant, the gum will be removed from palm oil by utilizing phosphoric acid or citric acid. next to bleaching section, the coloring matter and other metal ions will be absorbed or removed.