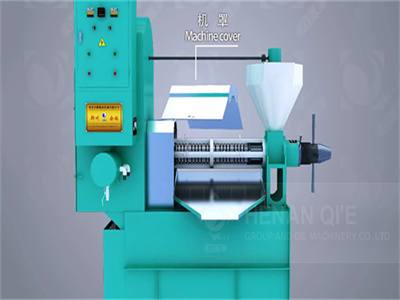

kenya membrane oil filter press membrane oil filter press

- Applicable Industries:Retail

- After-sales Service:Engineer's on-site guidance

- Dimension (L*W*H):1540*510*680mm

- Production capacity:0.8-1t/24h

- Voltage:380V

- Weight:580kg

- Power:90+11+5.5kw

- Advantage:Long Service Life

- Raw material range:palm,peanut,mustard,rice bran,peanut

- Transport Package: Fumigated Wooden Box or as Customer′s Request

- Function:Oil Production

membrane filter press manufacturers exporters suppliers

the traditional yo-tana membrane filter press uses 16 bar squeezing press achieves an average yield of 78 80 % on normal palm oil. because of its simplicity and flexibility, the chamber filter press has been widely applied in clarification and dewatering applications.

membrane filter press for refined palm oil vegetable oil

membrane filter press for refined palm oil vegetable oil filering , find complete details about membrane filter press for refined palm oil vegetable oil filering,oil filter press,hepa filter,membrane press filter from water treatment supplier or manufacturer-henan dazhang filter equipment co., ltd.

palm oil fractionation separation,membrane filter press

the initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. more specially for palm oil refinery, fractionation process is required in which palm olein and palm stearin are separated by scientifically cooling the refined palm oil by chilling plant and then filtering the oil.

china oil industry sludge membrane filter press for oil

china oil industry sludge membrane filter press for oil filter, find details about china filter press, press filter from oil industry sludge membrane filter press for oil filter jiangxi province county mining machinery factory

membrane filter press for oil fractionation

the membrane filter press is designed by swedish company (novatek a.b) whereas our principal has experience with filter press system for more than 20 years in various fields. the products ranged from manual membrane hydraulic presses to semi-auto and fully automated membrane hydraulic presses.

membrane filter press mse filterpressen® (oem)

due to its excellent filtration results, the membrane filter press has proven itself in a number of applications, e.g. in mining, chemical or pharmaceutical industries. in order to meet the different requirements of industry and municipalities, mse membrane filter presses are designed in modular design analogous to chamber filter presses.

membrane filter press

introduction of automatic membrane filter press: on the basis of hydraulic filter press, automatic membrane filter press is equipped with plc control to realize auto plate shifting. it can save labor resource in largest degree. auto membrane filter press is used in printing dyeing industry and papermaking industry. the cake moisture is below 35%.

membrane filter press met-chem what is membrane filter

a standard filter press application for metal hydroxide sludge, for example, with plates that provide a 32mm cake thickness generally takes about 4 hours to fill. the unit is usually 80% full at about the 2-hour mark. due to the high press (100 psi from the diaphragm pump being counteracted by the 4,000 psi of hydraulic press), resistance builds and the diaphragm pump begins to slow down.

membrane filter press machines nmp

the working room of the membrane filter press consists of chambers, limited by two adjacent plates with recesses in the central part. unlike the chamber plates, the drainage draining the filtrate is located on movable membranes serving for pressing and “wringing” of the filtrated cake.

membrane filter plates filtration products micronics, inc

membrane filter plates have a chamber below the drainage surface that may be inflated. the common method used is water press, which is generated by pumping into the squeeze cavity to inflate the face of the plate against the filter cake.air may also be used. membrane plates are used to reduce the cake moisture content or shorten the filtration cycle time.

automatic membrane filter press for squeeze filtration

membrane filter press offers high dewatering efficiency. automatic membrane filter press can provide filtration for effective dewatering and ensure the machine to provide the best solid-liquid separation solution. it can squeeze the filter cakes after the material-feeding process, which improves the dewatering efficiency of the machine, and increases dryness factor of filter cake.

newly membrane filter advantage of twice squeezing

1.program-controlled automatic filter press 2.membrane filter press 3.hydraulic compress filter press 4.mechanical compress filter press 5.jack filter press 6.cast iron plate and frame amber filter press 7.stainless steel plate and frame filter press 8.round plate filter press 9.cotton cake filter press 10.cardboard filter press 11.dy belt.

membrane filter press

andritz separation filter press sidebar sp air over oil (operating video) duration: 5:25.plate and frame membrane systems duration: 1:19. r. paul singh 9,627 views.

filter presses pmi group

our diverse range of filter presses are used worldwide for a variety of applications, including the palm oil industry. plate and frame filter presses recessed plate filter presses membrane filter press pmi filter presses are press filters for solid-liquid separation, and conform to international standards.

filter press

membrane filter press. membrane filter presses have a great influence on the dryness of the solid by using an inflatable membrane in the filter plates to compress remaining liquid from the filter cake before the plates are opened. compared to conventional filtration processes, it achieves the lowest residual moisture values in the filter cake.

membrane filter press manufacturers, suppliers

price : get quote any color : well design well adaptability : low operating cost filtering area : 10 m2- 80 m2 cake thickness : 30-35mm fully automatic : automatic membrane filter press filtering press : 6 bars -12 bars the working room of the membrane filter press consists of chambers, limited by two adjacent plates with recesses in the central part. . unlike the chamber plates, the.

oil gas filtration produced water treatment frac

continuous process flux for oil/water separation is recorded between 200 2000 l/(m²h)! depending on the oil type. removal of oil and tss to below 1 ppm is possible at very high flux rates. this means that our filtration solution has become a viable alternative to hydrocyclones, induced gas flotations units, micro-flotation, and walnut.

micronics, inc. engineered filtration group

micronics is a global manufacturer of cost-effective filtration products and services including filter cloth, filter plates and filter presses. (603) 433-1299 request a quote

filter press manufacturers m.w. watermark

sizes and types of filter presses offered. we offer a broad array of filter press sizes to meet your needs. from our small 250mm/0.2 cuft [5.5l] portable pilot filter press, all the way to 2000mm/600 cuft [17000l], our selection provides the right size filter press for your specific project. (see full capacities chart below).

china membrane filter press operation for polyester wine

filter press machine, oil filter, filter manufacturer / supplier in china, offering membrane filter press operation for polyester wine, high effective program-controlled automatic filter press used in mining, metallurgy, petroleum, chemical, medicine, blood bank universal centrifuge for lab and so on.