kampala how does the palm oil bleaching process proceed oil mill

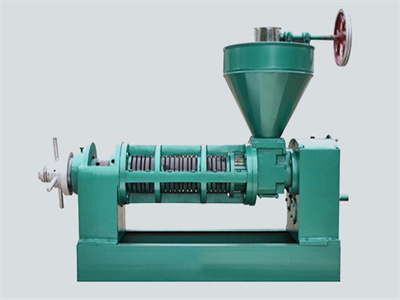

- Applicable Industries:Food and Beverage Factory

- After-sales Service:Free spare parts

- Dimension (L*W*H):1500*1200*1700mm

- Production capacity:200 tpd

- Voltage:220V

- Weight:580kg

- Power:4kw

- Advantage:Multifunctional

- Raw material range:cotton seed,olive,sesame,linseed,rice bran

- Transport Package: Export Wooden Crates

- Machinery Test Report:Provided

oil mill machinery vegetable oil refining oil extraction machinery how does the palm oil bleaching process

how does the palm oil bleaching process proceedme recent posts the palm oil production industry is one of the fastest growing in many oil-producing countries, taking the lead. the production of palm oil is relatively

how does the palm oil bleaching process proceed oil mill palm oil plant supplier

palm oil mill process includes 6 parts: palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery. 1. palm oil mill process of fruits receiving: collecting the ripe fresh cluster from the

palm oil refining processing plant palm oil refinery plant goyum screw press

palm oil refining consists of the following sections: bleaching deodorisation / de-acidification fractionation generally, refining process is necessary steps for the production of edible oils and fats products. the qualities of the finished

palm oil bleaching process oil pressing machine supplier

optimization of bleaching process aocs lipid library optimization of bleaching process introduction. it has also been found that a starting oil moisture content of 0.5 weight % in crude palm oil before the oil is subjected to dry-degumming (15

physical and chemical process in palm oil refining plant

palm oil physical refining process oil physical refining process, also called as oil steam refining. during the degumming section in the palm oil milling plant, the gum will be removed from palm oil by utilizing phosphoric acid or citric acid.

factory supply 2tph palm oil processing machine

source: poku, k. feasibility study on malawi palm oil mill establishment in year 3 there is the potential of processing 198 tonnes of fresh fruit bunches. assuming that the total quantity were to be processed in one location over a 20-day period

palm oil mill screw oil press machine

palm oil is extracted from fresh fruit bunches (ffb) by a mechanical process, where a mill commonly handles 2.5 to 150 mt per hour of ffb. the quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of

edible oil refining processes degumming / neutralization ,bleaching, deodorization,dewaxing (winterisation), dry fractionation, miscella refining

the bleaching process the unique chempro softbleach bleaching system gently removes residual phosphatides, metals, soaps and oxidation products in addition to colouring matters. the feedstock is heated up in the crude/neutral oil eco

palm oil / kernel oil business plan (august 2020) pdf

palm oil / kernel oil production processing mill business plan feasibility studies pdf this palm oil mill business plan is regularly updated and can also be used for bank loans, grants, proposal for competitions etc.

physical and chemical process in palm oil refining plant

palm oil physical refining process oil physical refining process, also called as oil steam refining. during the degumming section in the palm oil milling plant, the gum will be removed from palm oil by utilizing phosphoric acid or citric acid.

factory price small palm kernel oil extraction machine

5. palm kernel oil extraction 5.1 mechanical extraction mechanical extraction processes are suitable for both small- and large- capacity operations. the three basic steps in these processes are (a) kernel pre-treatment, (b) screw-pressing, and

4. traditional techniques and innovations in small-scale palm oil processing machine

traditional techniques and innovations in small-scale palm oil processing during the course of gathering material for this publication the author visited, and. it was observed that a steady evolutionary development

biodiesel production from crude palm oil by transesterification process science alert

an overflow system for batch esterification of crude palm oil (cpo) to obtain palm oil biodiesel (pob) was developed using a batch reactor (shake flask). the alkali catalyst of potassium hydroxide had been used to carry the transestrication proc

oil palm by product: how to compute its cost of production

oil palm by product: how to compute its cost of production,the palm oil processing industry has seen significant growth over the years, and the palm oil expeller has played a significant role in this growth.

palm oil / kernel oil business plan (august 2020) pdf

palm oil / kernel oil production processing mill business plan feasibility studies pdf this palm oil mill business plan is regularly updated and can also be used for bank loans, grants, proposal for competitions etc.

palm oil: processing, utilization and nutrition

palm oil mill effluent (pome) palm kernel 10 degumming bleaching deacidification and deodorization palm fatty acid distillate refining process rbd palm oil crude palm oil 180 260oc oc under vacuum filtration bleached palm oil 80oc 90oc 90

bleaching process technology plays an important role in edible oil refining_palm oil processing machine,edible oil machine plant,palm oil refining

oil bleaching purposes is not intended to remove all colors, but that improved oil color and provide qualified raw material for oil deodorized oil. these are henan huatai machinery brief section on edible oil decolorization, if you need palm oil

response surface optimization of palm oil bleaching using hydrochloric acid activated ukpor clay

the bleaching experiments were carried out in a batch process. 50 g of the refined palm oil were charged into a 250 ml beaker and 2 g of the activated clay samples were also added. the mixture of

palm oil production » european palm oil alliance

where does palm oil come froml palm crops grow in humid tropical conditions, which can be found 8 10 degrees north and south of the equator. originally found in west africa, the oil palm tree is now cultivated across asia, africa and latin

sources of chloride contaminants in palm oil mill

process. meanwhile, the european commis-sion has drafted a regulation to limit ge to below 1 ppm in all kinds of refined oils. then palm oil board is also taking the lead to introduce chloride limitations as one of the specifications in

palm oil mill effluent feedipedia

an industrial oil palm mill produces about 2.5 t of effluent per tonne of palm oil, or 0.5 tonne of effluent per tonne of fresh fruit (ho et al., 1984; pérez, 1997). palm oil mill effluent is a highly polluting material and much research has

edible oil refining processes degumming / neutralization ,bleaching, deodorization,dewaxing (winterisation), dry fractionation, miscella refining

the bleaching process the unique chempro softbleach bleaching system gently removes residual phosphatides, metals, soaps and oxidation products in addition to colouring matters. the feedstock is heated up in the crude/neutral oil eco

palm oil sciencedirect

the oil palm, being the highest yielding oil crop and its versatile oil uses besides food would play an increasingly important role, especially with new countries venturing into planting oil palm. the challenge is to be able to produce more palm