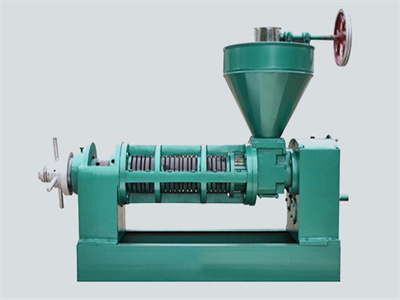

india palm kernel castor oil mill oil press hydraulic palm kernel

- Applicable Industries:Machinery Repair Shops

- After-sales Service:Free spare parts

- Dimension (L*W*H):1900*1750*1540mm

- Production capacity:7-9 T/24hrs

- Voltage:380V/50HZ/Triple phase

- Weight:560kg

- Power:2.2-18.5kw

- Advantage:Best mnufacturer

- Raw material range:linseed,sesame,peanut,rice bran,coconut meat

- Transport Package: Container

- Function:Oil Production

palm kernel oil expeller for cold pressing of palm kernel oil extraction machine

palm kernel oil press machine applications. our palm kernel oil press is suitable for pressing high-oil-content oilseeds such as shelled peanuts, tea seed kernels, sunflower kernels, cottonseed kernels, rapeseed kernels, walnuts, rubber seeds and peeled soybeans at room temperature or at low temperature.

palm kernel palm kernel coconut hydraulic oil press

palm kernel crushing machine,palm kernel crusher for palm kernel oil seed oil press. palm kernel crushing machine is to separate palm kernels from palms automatically and efficiently. low noise and energy consumption. high in saturated fats. palm kernel oil contains 48.2% lauric acid, 16.2% myristic acid, 8.4% palmitic, 3.4% . know more

palm kernel oil pressing machine palm oil mill machine

the pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing. palm kernel filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.

palm kernel oil production line, palm kernel oil extraction machine

our palm kernel oil production line’s capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil production and refining process design, manufacture, installation, commissioning and after-sales service if it is needed.

palm kernel oil extraction machine

palm kernel oil is an edible plant oil derived from the kernel of the oil palm elaeis guineensis. it should not be confused with the other two edible oils derived from palm fruits: palm oil, extracted from the pulp of the oil palm fruit, and coconut oil, extracted from the kernel of the coconut. palm kernel oil, palm oil, and coconut oil are three of the few highly saturated vegetable fats.

process flowchart for palm kernel oil production with good price

palm kernel processing flow chart shows how the seed is processed to make oil from palm kernel seed. leading manufacturer of palm kernel oil press machine.

how to produce refined vegetable oil from palm kernel oil extraction machine

palm kernel oil is the main output of any palm kernel oil expelling process. palm kernel oil consist mainly of glycerides and, like other oils in their crude form may consist of small and variable portions of non-glyceride components as well. ln order to render the oils to an edible form, some of these non-glycerides need to be either removed.

refining of palm kernel oil project topics

palm kernel oil is not usually extracted on the plantations, though occasionally mill contain press designed for this purpose. the conditions for the release of palm kernel oil, which is liquid at tropical day temperatures, are different from those of palm oil, but similar to those of copra and hand oil bearing seeds.

palm oil and palm kernel oil extraction process palm oil

9.palm kernel press oil. palm kernel oil extraction process, including crushing, rolling billet, steaming and pressing. its production process and equipment similar to the general oil. 10.steam boilers. the fibers and core shells are transported to the boiler for use as fuel.

palm oil mill processing machines palm oil mill machine

palm oil mill plant flow chart introduction: 1.palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. 2.palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of.

palm oil mill process_manufacture palm oil extraction

6.palm oil mill process of palm kernel recovery: press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating.the separated fiber material is sent to the boiler room as fuel; the separated stone is transported to stone warehouse by pneumatic conveying system for temporary storage.

palm kernel oil press machine automatic cold pressed oil machine

s. sefa-dedeh, in encyclopedia of food sciences and nutrition (second edition), 2003. oil seed processing. oil processing is an important activity in many rural areas in africa. the major oils processed are palm oil (elaeis guineensis), palm kernel oil (elaeis guineensis), coconut oil (cocos nucifera), groundnut oil (arachis hypogaea), and shea butter (butyrospermum parkii).

palm kernel oil press plant palm oil mill machine

palm kernel oil pressing machine. type: palm kernel oil pressing processing material: palm kernel capacity: 200-3000t/d palm kernel oil pressing equipment: crusher, dryer, oil expeller application: high efficiency crude oil pressing from palm kernel with low oil residual palm kernel oil pressing plant flow chart: main process in palm kernel press line: palm kernel cleaning : it is

palm kernel oil press machine automatic cold pressed oil machine

palm oil and palm kernel oil, obtained from the pulp and seed, respectively, of the oil palm (elaeis guineensis), accounted for ~ 30% of global fats and oil production in 2008. palm oil was the leading edible oil produced, overtaking soybean oil which accounted for ~ 23% of global production.

how to refine palm kernel oil leading manufacturer

alkali neutralization; adds the mixture of liquid caustic soda (1.5% of crude palm kernel oil weight and with 160 baume) and the liquid sodium salt (0.5% of the crude palm kernel weight) into the crude palm kernel oil, then stir it rapidly at the speed of 60 r/min for about 10 to 15 minutes, and followed by the stirring slowly at the speed of 27 r/min for 40 minutes.

palm kernel oil extraction machine, palm kernel oil extraction machine

crude corn oil processing machine palm kernel oil extraction machine product name mini oil press machine capacity 5-10tpd motor power 300-700w rated power 700w dimension 448*180*295mm packing dimension 570*290*355mm net weight 10.5kg gross weight 13.5kg detailed images

about us palm oil mill machine leading manufacturers

who we are leading manufacturer of edible oil mechanical equipment. factory with more than 30 years manufacturing experience. school-enterprise partner of henan technology university. what we do 10-500t/h oil material first cleaning,drying and storage section turn-key project. 100-3000t/d oil pretreatment,shelling and pre-press workshop turnkey project (soybean hot peeling.

palm kernel oil extraction production process and profit

the article tells us the viability of the business. we see that the demand for crude palm kernel oil (cpko), palm-kernel cake (pkc) and palm kernel sludge (pks) in the market is very huge, and as a matter of fact, the demand for it is all year round plus the profit in this business is amazingly good.

palm kernel oil machineoil press machinery,oil

palm kernel pre-treatment is indispensable to get pure palm kernel oil; more important,the clean palm kernel is favor to protect oil press and extend its working life. a.vibrating screen is used here to sieve sand, stones and other debris; at the same time, magnetic separators are adopted to separate metal debris.

palm kernel

the palm kernel is the edible seed of the oil palm fruit. the fruit yields two distinct oils: palm oil derived from the outer parts of the fruit, and palm kernel oil derived from the kernel. the pulp left after oil is rendered from the kernel is formed into &034;palm kernel cake&034;, used either as high-protein feed for dairy cattle or burned in boilers to generate electricity for palm oil mill the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.