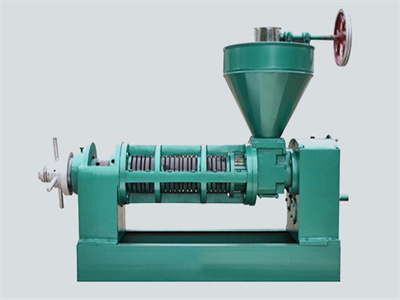

high grade running well cooking oil refining machine

- Applicable Industries:Manufacturing Plant

- After-sales Service:Field installation, commissioning and training

- Dimension (L*W*H):1450*870*1180cm

- Production capacity:50-100 t/24h

- Voltage:220v/110v

- Weight:160kg

- Power:0.85kw

- Advantage:Multifunctional

- Raw material range:rice bran,grape seed,walnut

- Transport Package: Export Wooden Crates

- Press type:Hot Press Oil Machine

loss cost edible oil mill machinery cooking oil refining

loss cost edible oil mill machinery cooking oil refining machine , find complete details about loss cost edible oil mill machinery cooking oil refining machine,vegetable oil mill machinery,cooking oil refining machine,cooking oil mill machinery from oil pressers supplier or manufacturer.

manufacturering cooking oil making machine, edible oil

cooking oil making machine manufacturer supplies high quality low cost price cooking oil processing machine, edible oil refinery machine. offer turn-key service for vegetable oil processing plant projects.

buy suitable cooking oil machine for starting your small

global market of cooking oil manufacturing business. due to the many economic benefits associated with lower overhead and maximum production rates, running small scale cooking oil production business is becoming a hot project to invest in, especially, uganda, etc. smaller cooking oil manufacturing plant can also produce high quality edible oil from various oilseeds.

palm fruit oil mill most effective oil seed press

cooking oil processing machine, cooking oil processing machine. palm fruit hot oil making press machine and palm cooking oil making machine up to 5 years warranty highly automatic us $999.00-$3999 / set 1 set (min. order) 2 yrs henan qi'e grain and oil machinery co., ltd...

highly efficient oil pressing and refinery projects

5tpd mustard oil mill pressing plant 1tpd mustard oil refinery line. this small mustard oil mill plant (5tpd oil pressing and 1tpd refinery) was built, using the most cost effective oil processing machinery to produce high grade edible mustard oil.

build your own small cooking oil refinery plant for making

complete cooking oil refinery process. the process of oil refining in cooking oil refinery plant can be carried out in two different types: continuous refining process and the batch refining process. this mini oil refinery machine belongs to batch refinery. although the two process have more similarities than differences, the one aspect that sets them widely apart is the production output.

cooking oil refining, cooking oil refinery, cooking oil

at tinytech udyog, we design and supply cooking oil refining plants which fulfill the above motive of impurity removal. our cooking oil refinery is designed to have series of steps such as degumming (to remove gums), neutralizing (to remove ffa), bleaching (to remove color), deodorizing (to remove odor and taste), and dewaxing (to remove waxes).

small oil refinery machine

how to use oil refining machineni capacity cooking oil refinery machine mainly applied some small oil workshops or home use. https://goo.gl/rfjqzq.

physical and chemical cooking oil refinery machine

physical and chemical cooking oil refinery machine. the physical refining process is possibly the most important step in cooking oil refinery machine and is aimed at creating a fatty acid free, odourless product with a very light hue and very stable against oxidization.chemical cooking oil refinery machine is performed in order to remove the fatty acids from the crude oil that is extracted.

best quality hemp oil extraction machines on the market

the super c extractor is definitely one of the best hemp oil extraction machines for making high-grade cannabis oil at home. the price. $3,200. the good. this extraction machine will fit on a table top so you won’t have to go crazy finding space for it. you’ll need a tank of co2 to get your solvent into the device. the bad

chapter 5 : processing and refining edible oils

soybean oil, which is high in g-tocopherol and consequently well-protected in vitro, is relatively low in a-tocopherol and cannot reach this ratio. the, b-carotene in palm oil is another valuable component that needs consideration in the refining process. special processes for retention are being designed.

oil gas engineering refineries need machine learning

in the book thinking, fast and slow by daniel kahneman, machine learning is described as “the science of getting computers to learn and act like humans do, and improve their learning over time in autonomous fashion, by feeding them data and information in the form of observations and real-world interactions.” commonalities between the human mind and machine learning technology include:

cooking oil manufacturing machine, cooking oil

the oil after drying and dewatering can be automatic hoisted to decoloring pot, and finished whole refining process. 4.the oil quality outcome standard- cooking sunflower oil refinery machine 1). 5.oil from cooking sunflower oil refinery machine 6.machine pictures-- cooking oil refinery machine/sunflower oil refinery machine

cooking oil refinery batch type vegetable oil refinery

we present one of the most developed cooking oil refinery plant for processing of edible oil. there are primarily involved two types of processing- batch type and continuous. through these processes, the oil is separated from impurities and other materials that can make it unfit for edible purpose.

used cooking oil refinery, used cooking oil refinery

factory offers 114 used cooking oil refinery products. about 1% of these are machine oil purifier, 15% are oil pressers. a wide variety of used cooking oil refinery options are available to you, such as usage, condition, and local service location.

cost accounting and cost management in edible oil refinery machine

this gl o macs finance budgeting training course on cost accounting and cost management in edible oil refinery machine provides the essential knowledge and skills to enable delegates to successfully control costs; prepare, manage and control budgets in the oil refinery sector. it also provides solutions to the strategic issues currently facing major.

oil maker machine for home order shreeja oil extraction

we have gained remarkable success in the global market by producing oil maker machine, oil extraction machine, and mini oil ghani, fiter press,automatic oil press machine is newly developed oil mill machine that is designed with heating system and oil filtering system.

cooking oil refinery machine home facebook

alkali refining in the cooking oil machinery in the cooking oil machinery, when refining the oils. the main function of the process of alkali refining in the deacidfication section is: caustic soda can neutralized most of the ffa in the crude oil, formation of fat sodium salt (sodium soap) is not easy to dissolve in the oil, becoming to floc gelatinous and settle down; the neutralization.

mustard oil refinery machine, mustard oil refinery machine

1,750 mustard oil refinery machine products are offered for sale by suppliers on sale, of which oil pressers accounts for 51%, machine oil purifier accounts for 1%, and machine oil filter accounts for 1%. a wide variety of mustard oil refinery machine options are available to you, such as palm oil, soybean oil, and sunflower oil.

the process of crude oil refining eme 801: energy

the process of crude oil refining. once crude oil is extracted from the ground, it must be transported and refined into petroleum products that have any value. those products must then be transported to end-use consumers or retailers (like gasoline stations or the company that delivers heating oil to your house, if you have an oil furnace).