ethiopia germany 2024 sunflower oil vegetable oil refining process

- Applicable Industries:Farms, Restaurant

- After-sales Service:Free spare parts, Video technical support

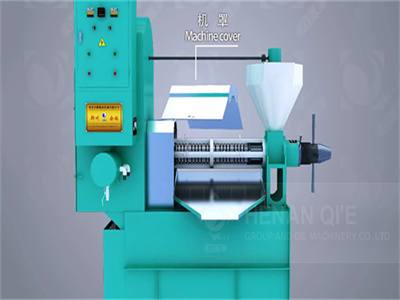

- Dimension (L*W*H):2150*1300*1550mm

- Production capacity:80 ton/day

- Voltage:380V/50HZ/Triple phase

- Weight:570kg

- Power:37~45kw

- Advantage:High Oil Yield

- Raw material range:walnut,soybean,baobab seed,pine nut,grape pip

- Transport Package: Container

- Certification:CE and ISO900

vegetable oil

vegetable oils, or vegetable fats, are oils extracted from seeds, or less often, from other parts of fruits. like animal fats, vegetable fats are mixtures of triglycerides. soybean oil, rapeseed oil, and cocoa butter are examples of fats from seeds. olive oil, palm oil, and rice bran oil are examples of fats from other parts of fruits. in common usage, vegetable oil may refer exclusively to.

batch type crude cooking oil refining production machine

batch type crude cooking oil refining production machine small scale edible oil refining machine , find complete details about batch type crude cooking oil refining production machine small scale edible oil refining machine,palm oil refinery,refined sunflower oil from,palm oil refinery tanks from oil pressers supplier or manufacturer-henan doing environmental protection.

sunflower seeds oil refining machine crude oil

cooking oil production line are mounted units category a few brands pt international brand you will find in our inventory. find sunflower seeds oil refining machine crude oil refining machine to see what's in pt international manufacturer name stock! oil expeller, oil press and oil refinery machine supplier

best price of palm oil press machine for sale

manufacture palm oil processing line,low cost price. palm oil processing line is an important production line of extracting palm oil,the palm oil processing line mainly includes: palm oil press production line and palm oil refinery line.the palm oil processing line can help you get standard edible oil or provide qualified material for deep processing products.the production.

manufacturering cooking oil making machine, edible oil

providing edible oil refinery plant. edible oil refinery plant is to refine the crude oil obtained from pressing and solvent extraction plants. only after refining, the crude oil becomes edible oil. based on the requirements of the clients, the company can provide three types of edible oil refinery batch, semi-continuous and fully continuous.

cotton oil refinery machine manufacturers suppliers

oil refinery machine. china oil refinery machine catalog of hot sale mini corn germ oil refinery groundnut oil refine machine andoil refinery mini plant, almond oil refinery machine for crude edible oil palm kernel oil refining equipment provided by china manufacturer,the oil must go through several stages of purification, including degumming, deacidification, bleaching, dehydration, and dephosphorization. after the oil is refined, it can be sold or consumed directly.

vegetable oil refining de smet engineers contractors

vegetable oil refining. edible oil production is able to process different qualities of products depending on the needs of the market. for some cases the clients may only need the process of vegetable oil extraction, but in order to have the premium quality oil, the vegetable oil refining process will be required.. de smet engineers contractors can assist your company to decide the best.

vegetable oil processing machine

and to review suggested nopa process diagrams for incorporation into the final report. this discussion presents information on the soybean processing industry and a description of the refining of edible soybean oil. the review of nopa diagrams consisted of a discussion of process flow diagrams previously submitted . to . epa by nopa.

dewaxing process, oil dewaxing process, sunflower oil

dewaxing may be the fifth process considered for the edible oil refining. it is not a compulsory process and it is not required for every type of oil. dewaxing is performed only for high wax containing oils such as sunflower oil, rice bran oil, corn oil etc.

vegetable oil refinery, vegetable oil refinery plant

the refining capacity of the vegetable oil refinery is generally expressed as tons per day (tpd) in 24 hours. thus, an oil refinery must operate continuously for 24 hours a day to get the output results and to allow the adequate time for process completions.

vegetable oil processing machine

oil bleaching is a step in the process of crude oil refining. in the bleaching technology, bleaching earth is applied to crude oil, minimizing its content of pigments (e.g., carotenes and chlorophylls), heavy metals, and the phosphorus remaining after degumming. this improves the appearance and taste of the oil.

sunflower oil production line for sunflower oil plant

sunflower oil production process introduction. sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process.sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body, and is.

good performance screw sunflower oil press production line

sunflower oil screw press cooking oil project. henan lingfine machinery co., ltd. is a professional engineering modern enterprise specializing in various kinds of vegetable oil, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line, essential oil and pigment extraction machine, has engineering.

manufacturing vegetable oil press machine, mini oil press

we company is a leading manufacturer specialized in cooking oil making machine with capacity 10-2000tpd.we can offer cooking oil press machine,oil extraction machine,oil refinery fractionation plant.

faq about vegetable oil processing technology oil extraction

oil drying system: the function of the oil drying system is to evaporate the moisture in palm crude oil. this can prevent palm oil from deteriorating and extend the shelf life of palm oil. 3d palm oil producing plant. of course, due to the difference in the final product, you can also use palm oil refining machines and palm oil fractionation.

getting more, using less: how enzymes increase yield

oil processors using our enzyme solutions will reap several sustainability benefits; for example, they will save on energy costs because there’s less need for heat exchanging. we actually conducted a lifecycle assessment to analyze the carbon footprint of a conventional vs. enzymatic refining process using purifine® pla1.

deodorization oil chemists&039; society

1.5% for oils rich in linolenic acid (soybean oil, rapeseed oil, canola, etc.) 1.0% for other vegetable oils (corn oil, sunflower oil, etc.) tocopherols: min. 500 ppm (to guarantee good oxidative stability) polycyclic aromatic hydrocarbons (pah) new eu regulation 835/2011 in force since september 1, 2012 2 ppb bap and 10 ppb pah4 for most.

winterization of oil

winterization of oil is a process that uses a solvent and cold temperatures to separate lipids and other desired oil compounds from waxes.winterization is a type of fractionation (also known as fractionate crystallization), the general process of separating the triglycerides found in fats and oils, using the difference in their melting points, solubility, and volatility.

sunflower oil: worldwide expertscape.com

the dietary treatments consisted of 2.5% added oil or fat from three sources as follows: sfo diet containing sunflower oil; lrd diet containing lard, and evoo diet containing extra-virgin olive oil. dietary oil or fat type improved significantly body weight and gain as well as feed efficiency in birds fed evoo compared to those fed the other.

refining of vegetable oils for biofuels us

refining of vegetable oils for biofuels. view pdf. there is considerable growth in the use of vegetable oils such as palm, rape seed, soybean, sunflower, etc. as an alternative to petroleum based diesels. currently there are two options for this; straight vegetable oil (svo) and biodiesel.