crude oil refining additives and catalyst in pakistan

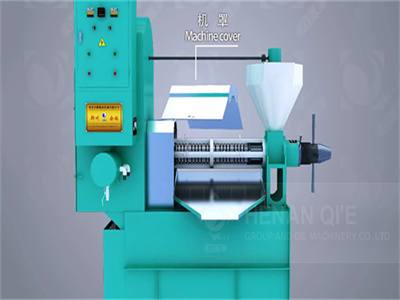

- Applicable Industries:Machinery Repair Shops

- After-sales Service:Free spare parts

- Dimension (L*W*H):1650×1440×1700mm

- Production capacity:10-150 ton/day

- Voltage:440V

- Weight:808kg

- Power:45kw

- Advantage:High Efficiency

- Raw material range:palm,linseed,baobab seed,sunflower seed,shea nut

- Transport Package: Export Fumigation-Free Wooden Box

- Origin:Zhengzhou, China

china sonangol sign an mou for a crude oil refinery project

24-09-2013. china sonangol sign an mou for a crude oil refinery project. on the 24th of september 2013, the supreme energy council of, presided by his highness sheikh ahmed bin saeed al maktoum, and china sonangol international pte ltd represented by ceo mr. alain fanaie signed a memorandum of understanding to build, own and operate a crude oil refinery, the united arab

clariant refinery services opens state-of-the-art crude

28-01-2020. clariant refinery services opens state-of-the-art crude and fuel oil lab in the uk. clariant refinery services, a global leader in developing additives for better fuel transportation, has opened a new state-of-the-art crude and fuel oil laboratory that will focus on applications for transport and storage.

lost in oil’s rally: $2 trillion-a-year refining industry

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin. the cuts that trump brokered lifted crude prices, with benchmark brent crude soaring from $16 to $42 a barrel in the space of a few months.

gazprom neft’s omsk refinery increases efficiency in crude

13-09-2019. gazprom neft’s omsk refinery increases efficiency in crude oil distillation. gazprom neft’s omsk refinery has embarked on a project to modernise its avt-10 crude distillation unit (cdu) — an initiative which will see the complex expand its range of light oil products by five percent, increasing production of aviation kerosene and diesel fuels.

oil refinery cracking crude oil to diesel waste engine oil

oil refinery cracking crude oil to diesel waste engine oil catalyst introduction of vilcon-5 catalyst 1) 1 mt catalyst can pyrolysis about 500-1,000 mt waste plastic/ waste tires/waste engine . 2) recycle 2-3 times.

edison explains

amounts, such as fuel oil, coke, asphalt oil, waxes and lubricants. what is the first stage of crude oil refiningst refining techniques start with crude distillation unit (cdu) refining, whereby crude is heated to separate it into its different component substances. the crude is initially heated to 100–137oc then passed

refinery fuel additives dorf ketal

you need refinery fuel additives that comply with the latest fuel specifications. dorf ketal can help. dorf ketal is the only company that develops, manufactures and services refineries with process chemicals for refining operations and fuel additives for finished fuels.

processing high tan crude: part i refining, gas

article summary. the trend in crude oil supplies after 150 years of petroleum processing is towards heavier, lower quality feedstocks. according to eni group of italy, the ratio of heavy crude oil (api 10–26) in the total crude oil slate rose from 11% in 1995 to 14% in 2005, and the trend in recent years has accelerated.

lost in oil’s rally: $2 trillion-a-year refining industry

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin. the cuts that trump brokered lifted crude prices, with benchmark brent crude soaring from $16 to $42 a barrel in the space of a few months.

edison explains

amounts, such as fuel oil, coke, asphalt oil, waxes and lubricants. what is the first stage of crude oil refiningst refining techniques start with crude distillation unit (cdu) refining, whereby crude is heated to separate it into its different component substances. the crude is initially heated to 100–137oc then passed

oil refinery cracking crude oil to diesel waste engine oil

oil refinery cracking crude oil to diesel waste engine oil catalyst introduction of vilcon-5 catalyst 1) 1 mt catalyst can pyrolysis about 500-1,000 mt waste plastic/ waste tires/waste engine . 2) recycle 2-3 times.

intercat fcc additives and catalyst handling technologies

intercat fcc additives and catalyst handling technologies. most refiners now find it essential to use catalytic additives to supplement the host fcc catalyst in order to achieve the desired unit performance, product quality, and environmental emissions targets that must be met.

lost in oil’s rally: $2 trillion-a-year refining industry

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin. the cuts that trump brokered lifted crude prices, with benchmark brent crude soaring from $16 to $42 a barrel in the space of a few months.

edison explains

amounts, such as fuel oil, coke, asphalt oil, waxes and lubricants. what is the first stage of crude oil refiningst refining techniques start with crude distillation unit (cdu) refining, whereby crude is heated to separate it into its different component substances. the crude is initially heated to 100–137oc then passed

crude oil flow improvers market global industry analysis

crude oil flow improvers are additives that deliver apt solutions in all the stages from reservoir to refinery and maximizes the production. drag reducing agents, one of the crude oil flow improvers reduces the turbulence and assures increased flow rate and throughput inside the pipelines.

refining additives market global industry analysis, size

however, volatile crude oil prices in last 3-4 years moulds major upstream companies to close down its operations in order to reduce their losses will hamper the oil production rate. sudden decline in oil production rate hampers the refinery production and also hampers the refining additive consumption. refining additives market: regional outlook

oil refinery cracking crude oil to diesel waste engine oil

oil refinery cracking crude oil to diesel waste engine oil catalyst introduction of vilcon-5 catalyst 1) 1 mt catalyst can pyrolysis about 500-1,000 mt waste plastic/ waste tires/waste engine . 2) recycle 2-3 times.

introductory chapter: heavy crude oil processing an

an oil industry expert, professor emeritus peter odell, suggested that by 2100, the oil industry will be larger than in 2000 but up to 90% dependent on unconventional crude oils (high-acid crude oils, heavy crude oils, bitumen, and oil sand) .

edison explains

amounts, such as fuel oil, coke, asphalt oil, waxes and lubricants. what is the first stage of crude oil refiningst refining techniques start with crude distillation unit (cdu) refining, whereby crude is heated to separate it into its different component substances. the crude is initially heated to 100–137oc then passed

oil refinery cracking crude oil to diesel waste engine oil

oil refinery cracking crude oil to diesel waste engine oil catalyst introduction of vilcon-5 catalyst 1) 1 mt catalyst can pyrolysis about 500-1,000 mt waste plastic/ waste tires/waste engine . 2) recycle 2-3 times.

crude oil flow improvers market global industry analysis

crude oil flow improvers are additives that deliver apt solutions in all the stages from reservoir to refinery and maximizes the production. drag reducing agents, one of the crude oil flow improvers reduces the turbulence and assures increased flow rate and throughput inside the pipelines.

oil refinery management training seminar glomacs

this gl o macs refinery process yield optimisation training seminar will present a detailed overview of refining process yields, from the crude oil feed to the finished products. it is targeted at personnel directly involved in refining utilization and optimization, including but not limited to refining technologists and operations personnel as

fuel additives multisol

a range of cold flow and speciality additives for the refining and shipping industries, created by infineum to meet the challenges presented by the imo 2020 directive. these include effective solutions for the transportation of crude and fuel components, asphaltene and wax management, lubricity and combustion.

demulsifiers dorf ketal

crude oil desalting crude oil often contains water, inorganic salts, suspended solids, and water-soluble trace metals. as a first step in the refining process, to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning the catalysts in processing units, these contaminants must be removed by desalting (dehydration).