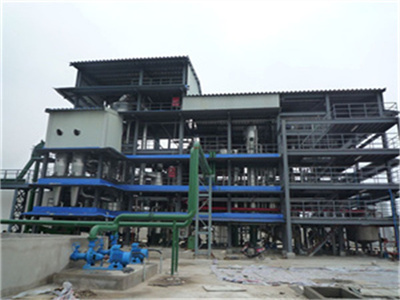

crude oil palm kernel oil refining works refinery in ghana

- Applicable Industries:Farms, Restaurant

- After-sales Service:commissioning and training

- Dimension (L*W*H):1700*1300*1850mm

- Production capacity:5-30t/d

- Voltage:220v 50hz

- Weight:1900kg

- Power:7.5-11kw

- Advantage:Top brand

- Raw material range:soybean,sesame,linseed,rapeseed,palm fruit

- Transport Package: Wooden Case Packaging

- Warranty:1 Year

sunflower palm oil refining machinery refinery cost

palm oil plant supplier 1-5tpd palm oil press sunflower palm oil refining machinery refinery from.crude oil distillation machine,soybean palm kernel sunflower oil refining machine,corn ... palm oil refined extraction equipement / mini crude oil refinery plant /crude oil refinery for sale_okchem. palm oil refined extraction.

how to refine palm kernel oil leading manufacturer

alkali neutralization; adds the mixture of liquid caustic soda (1.5% of crude palm kernel oil weight and with 160 baume) and the liquid sodium salt (0.5% of the crude palm kernel weight) into the crude palm kernel oil, then stir it rapidly at the speed of 60 r/min for about 10 to 15 minutes, and followed by the stirring slowly at the speed of 27 r/min for 40 minutes.

refinery palm oil process_manufacture palm oil extraction

refinery palm oil process is mature technology in china. the purpose of refinery palm oil process is to removal the impurities to meet the standards of edible oil. and the refinery palm oil processes are: crude oil ---degumming bleaching---deodorization---fractionation. steps of refining process of palm oil are as follows:

palm oil and palm kernel oil refining and fractionation

because the refining and fractionation processes are continuous in the refinery, it is not possible to follow a single identifiable batch of crude palm oil through the refinery.

palm oil production and refinery process

crude palm oil refining process is used for transforming crude palm oil into refined palm oil, and we manufacturer sale various capacity palm oil refining machine.our palm oil refining process are exported to around the world ... next: palm kernel oil pressing and refinery process. leave a message. if you want to know more information about.

palm oil refinery palm oil mill machine leading

palm oil refinery flow chart: basing on the traditional oil refining technology, our company has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality.

oil refining palm oil mill machine leading manufacturers

small scale oil refinery plant. type: crude oil refinery plant processing capacity: 1 ~ 5t / d processing material: palm oil,palm kernel oil, peanut oil, rapeseed oil, cottonseed oil, sunflower oil, corn germ oil, animal oil etc. small scale oil refining plant introduction: our small scale oil refinery plant are great choice for small capacity oil refinery machine.the

refining of palm kernel oil project topics

the crude palm kernel oil was first washed with distilled water by heating the mixture in an electric heater for about 2 hours to reduce the impurities present in the oil in their crude form, degummed with phosphoric acid and neutralized with naoh (caustic soda).the saponification value, iodine value and acid value was analyzed and their values.

manufacture palm kernel oil refining process/crude oil

manufacturing palm kernel oil refining process/crude oil refining machine,the purpose of palm kernel oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces.

flow chart of the production chain of palm oil and palm

(only for palm kernel oil) c medium high 4 bap levels may be found in crude palm kernel oil due to bad drying practices. bap is an indicator for pahs. ec regulation no. 1881/2006 sets a limit of 2.0 μg/kg for bap and a limit of 10 μg/kg for four pah in oils and fats intended for direct human consumption or use as an ingredient in foods.

palm oil refinery process pdf

refining is an essential process for a complete palm oil production line because there are still some impurities such as phospholipids, ffa, pigment, odor, etc. in the crude palm oil. in order to increase the stability and improve the nutritional properties of crude palm oil it is necessary to treat the oil by a series of processes, that are.

cost on palm oil refinery plant

palm oil refinery set up cost. the cost to start and operate a palm oil refinery plant covers a lots of aspects. abc machinery, as a reliable and professional manufacturer and supplier for palm oil processing machinery and palm oil refining equipment, will tell you how to calculate the cost of running a palm oil refinery plant.. cost of setting up a crude palm oil reinery plant

palm oil refining process golden agri-resources

there are many steps needed before we get that golden palm oil you see at the supermarket. one of the main steps in this long process is palm oil refining. at golden agri-resources’ (gar) six palm edible oil refinery machine, several processes take place to purify the crude palm oil (cpo) before it is ready for distribution to consumers and industries.

new technology waste palm oil refinery plant grain

no waste water treatment palm kernel oil refining machine from expellers or edible oil refining machine plant contains work flow of new technology palm oil . send inquiry; find fractionation technology palm oil refining plant. fractionation technology palm oil refining plant offers 10-20kg/t oil. oil content in waste is a new oil processing.

who moves the palm oil marketset the world’s largest

wilmar international (singapore) meet wilmar international, the largest palm oil trader and oleochemicals producer in the world.. headquartered in the old chinatown, with almost us$44 billion in yearly revenue wilmar is one of the largest agribusiness groups in the world and the w in the now acronym.. wilmar’s main business remains the refining and distribution of palm oil products.

manufacture 2tpd palm kernel oil refining machine,low cost

manufacturing 2tpd palm kernel oil refining machine,cooking oil refinery plant is used to process crude oil. the 2tpd palm kernel oil refining machine is used for removing the impurities of palm kernel oil, such as fatty acid, phosphatide, pigment.

palm oil refining processing machinery find edible oil

process flow chart: crude palm oil (cpo) is mainly further processed into edible oil for food purpose. to meet the international industry’s standards for edible oil, the crude palm oil produced by oil mill should be refined in palm oil refinery plan t. palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

turnkey project of palm oil refinery plant physical refining machine

crude palm oil (cpo) is mainly further processed into edible oil for food purpose. to meet the international industry’s standards for edible oil, the crude palm oil produced by oil mill should be refined in palm oil refinery plant.palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

oil product margins neste

usd/bbl, data updated daily. daily figure is based on last five (5) days rolling average.

small scale oil refinery plant palm oil mill machine

small scale oil refining plant introduction: our small scale oil refinery plant are great choice for small capacity oil refinery machine.the small scale oil refinery production plant can remove phospholipids, ffa, pigment, gums, waxes, off-flavor and other impurities in the oil.