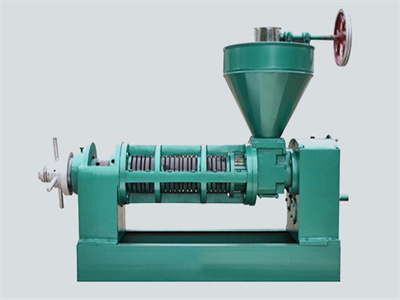

canola oil extractor canola oil extractor in joburg

- Applicable Industries:Food & Beverage Factory, Food Shop

- After-sales Service:24h Service Online

- Dimension (L*W*H):2500*14000*1800mm

- Production capacity:150-200 kg/h

- Voltage:110V/220V/380V

- Weight:140kg

- Power:18.5-22kw

- Advantage:Top brand

- Raw material range:baobab seed,avocado,peanut,flaxseed,hemp seed

- Transport Package: Wooden Case Packaging

- Color:Customer Required

characterization of canola oil extracted by different

introduction. canola oil is extracted from rapeseed and consumed all over the world due to its valuable ingredients [].it has a low amount of saturated and a substantial amount of monounsaturated fats with roughly 2:1 mono to polyunsaturated fatty acids [].in general, it contains 61% oleic acid which is classified as a monounsaturated omega-9 fatty acid, 11% α-linolenic acid and 21% linoleic.

cotton seed canola palm made small oil extraction machine

china canola oil press mustard peanut oil mill palm seed . oil mill, oil press, oil extraction machine manufacturer / supplier in china, offering canola oil press mustard peanut oil mill palm seed expeller, wholesale disposable folding dust facial masks n95 face mask, custom your own fda approved anti virus high alcohol sanitizing spray hand sanitizer in liquid gel and so on.

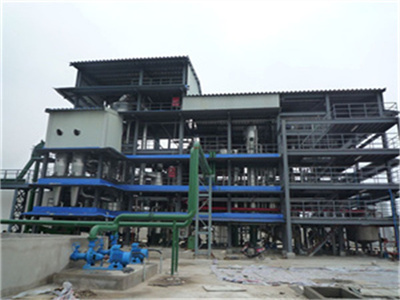

solvent extraction plant canola solvent extraction plant

canola solvent extraction plant are (canola) seeds contains more than 45% oil. the major oil is recovered by mechanical pressing in screw presses. the seeds are subjected either to pre-pressing in screw presses leaving left over residual oil in the cake in the range of 16 to 20% or the seeds are subjected to full pressing in which case oil left over has residual oil in the cake ranging between.

canola oil extraction machine manufacturer supplier

goyum screw press is a well-known manufacturer exporter supplier of canola oil extraction machine in ludhiana, canola oil extraction machine exporter punjab, canola oil extraction machine supplier ludhiana, canola oil extraction machine manufacturing export company.

influence of canola seed dehulling on the oil recovery

dehulling canola seeds provides an enriched cake in oil and proteins leading to an improved meal quality after oil extraction. the aim of this work was therefore to explore the impact of dehulling pre-treatment on both oil recovery and quality, using cold pressing followed by supercritical co 2 extraction. for this purpose, whole canola seeds, dehulled seeds, and reconstituted mixtures of 5%.

healthful oils: the canola controversy today's dietitian

however, only one gene in the plant has been modified, and genes are proteins. processing removes all proteins from canola oil, so canola oil made from gm seed is considered equivalent to canola oil from non-gm canola plants.8. once harvested, canola seeds are rolled or flaked to rupture the seed's cells and make the oil easier to extract.

quality of canola oil obtained by conventional

canola seeds were cleaned manually to remove husks and foreign matter, homogenously ground using a coffee grinder, sieved through 60 mesh (250 µm) screen, and stored at 4˚c in polyethylene bags until used for the ex- traction. 2.2.2. oil extraction . 2.2.2.1. soxtec extraction . oil was extracted from the ground canola seeds using the

canola / rapeseed processing crown iron works

the solvent extraction process uses hexane or other solvents to wash the canola or rapeseed oil from the prepared flakes. the design of the equipment varies so that crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run.

extraction of phospholipids from canola with supercritical

the potential use of supercritical (sc)-co2/ethanol mixture for the extraction and fractionation of phospholipids (pl) from flaked canola seeds, canola meal, and acetone insolubles (ai) was investigated. pl extraction was possible when ethanol was used as a cosolvent in sc-co2. pl recovery of 20.8% was achieved when canola flakes were extracted at 70°c and 55.2 mpa with sc-co2/10%etoh after.

canada to explore canola oil export opportunities to

according to the canola council of, canola generates one quarter of all farm cash receipts. exports more than 90% of its canola as seed, oil or meal to 50 markets around the world, bringing billions of dollars into. the biggest buyer of canola oil and meal is the united states.

soybean seed oil extraction processing oil mill

soybean seed oil extraction process,doing group is serving customers for soybean seed oil extraction process plant, this oil extraction plant can process 30,000 to 34,500 ton of soybean seeds every year, this plant is adopted (n-hexane) solvent extraction tech.

canola oil processing plant

for processing canola oil, we need canola oil seed, suction vibrating screen, magnetic separator, demineralizer, flaking machine, steam cooking machine, filtering machine, extractor, evapo-separated machine, steam drying machine, stripping tower, etc. there are mainly 2 methods for canola oil production: pressing method and extracting method.

effects of some plant extracts on the oxidative stability

dative stability of canola oil and its purified triacylglycerols (tags) were studied. the effects of extraction solvents (methanol, ethanol and acetone) on the extrac-tion yields, phenolic contents and antioxidant activities of these plant extracts were also determined. methanol extracts had the highest total phenolics (78.4–

improving oil extraction from canola seeds by conventional

canola seeds are one of the most important sources of edible vegetable oils globally. crude canola oil is industrially extracted from canola seeds by expeller-pressing of heat-preconditioned flaked seeds. the residual oil in the pressed “canola cake” is recovered by solvent extraction using hexane. however, hexane extraction may pose adverse safety and environmental impacts compared to.

factory direct supply canola fruit sesame/ginger garlic

feathers of factory direct supply canola fruit sesame/ginger garlic essential seed oil extraction machine. 1).the supercritical fluid extraction device has a wide scope of operation, extracting high purity, less solvent residue,etc 2).good selectivity, and can control the press and temperature, targeted to extract the required ingredients.

experimental research of oil extraction from canola by

the solvent is from 0.008 to 0.015 m 3, the mass of the canola seeds and soybean seeds is from 2 to 5 kg. the frequency of microwaves is 2450 mhz. in order to study the kinetics of the extraction process, the solution concentration was determined. the extraction of oil from the micelle to determine the concentrations was carried out arbitrarily by

custom screw press for canola oil extraction

french screw press for canola oil extraction french partners with customers to design and supply full press extraction and preparation systems that best meet their processing needs. before ordering french equipment, customers can conduct performance trials’s innovation center.

effects of some plant extracts on the oxidative stability

according to the rancimat and dsc results, rosemary extract was the most effective extract in stabilization of canola oil at 110c and 150c. tags containing rosemary and thyme extracts had longer induction periods than those of bht or bha‐amended tags at 200 μg/g concentration. however, bay solvent extract was the least effective in canola oil.

canola seed oil extraction plant oem manufacturer from mumbai

canola seed oil extraction plants available for edible and non edible oilseeds, soybean oil extractions in different small to large capacities. oil seeds preprocessing plants i.e decorticators, dehullers, delinters, copra cutters , seeds cleaners, destoners etc.