bulid rice bran oil production line in lesotho

- Applicable Industries:Machinery Repair Shops

- After-sales Service:24h Service Online

- Dimension (L*W*H):2100*1500*1750cm

- Production capacity:150-300 kg per hour

- Voltage:220v 50hz

- Weight:1315kg

- Power:2.2-18.5kw

- Advantage:Best mnufacturer

- Raw material range:rapeseed,soybean,sunflower seed,peanut,rapeseed,

- Transport Package: Wooden Case

- Machinery Test Report:Provided

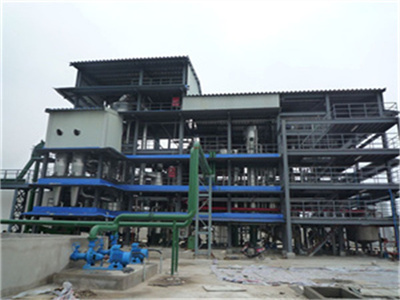

set up a rice bran oil factory oil production line large sacle

this is a small rice bran oil pressing factory build. the capacity of this small oil pressing unit is 5 tones per day (5tpd). prospect of rice bran oil production business. rice bran oil is a material that can be found in the outer layerlskin of a paddy seed, that can be obtained from screw pressing,milling or solvent extraction.

top 9 best rice bran oil refining machine

patanjali rice bran oil. patanjali rice bran oil is also one of the popular and best rice bran oil brands. this is a physically refined oils so, you be assure that it involves chemicals. it is rich in unsaturated fatty acids which are considered healthy for heart.

rice bran oil production line, rice bran oil production

factory offers 1,465 rice bran oil production line products. about 93% of these are oil pressers, 0% are plastic extruders, and 0% are other food processing machinery. a wide variety of rice bran oil production line options are available to you, such as usage, condition, and local service location.

rice bran oil production line cooking oil extraction machine

prosper choice import export offering rice bran oil production line, ss, ss metal, stainless steel metal, rice bran pretreatment is the first step in the rice bran oil extraction process. rice bran is easy to become rancid and difficult to preserve. the oil content is low, about 15-20%. therefore, in order to obtain the maximum oil yield, it is recommended that customers pretreat the rice bran first. the pretreated rice bran is easier to produce oil and can be stored for 10-15 days.

start your own rice bran oil mill project today!

when refers to rice bran oil production, the following three processing steps can not be ignored, they are raw material preparation, rice bran oil extraction and crude oil refining. rice bran raw material preparation : like other oil bearing materials, before making oil from rice husk , these raw materials should have been fully prepared.

rice bran oil ayurvedic ingredients uses benefits

ingredients rice bran oil. rice is made up of several layers, one of them being rice bran extract. this is derived from the brown, oily layer between the outer husk and the rice kernel inside and is referred to as ‘bran’. in ancient, rice bran oil was used to wash the skin and hair.

best sale rice bran oil machine oil processing plant

a wide variety of rice bran oil processing plant options are available to you, there are 963 rice bran oil processing plant suppliers, mainly located in asia. the top supplying countries or regions are china, and, which supply 98%, 1%, and 1% of rice bran oil processing plant respectively.

rice bran oil entrepreneurindia.co

with around 8% of world oilseeds production, over 7% of global protein meal production, around 4% of world oil meal export, total oilseeds production of 23 mn tonne and 5.6 mn tonne of edible oil production, is the fourth largest edible oil economy in the world valued at usd 16.5 bn (rs 660 bn).

rice bran: production, composition, functionality and food

rice bran is 18% to 22%. the fatty acid composition of rice bran oil consists of 41% monounsaturates, 36% polyunsatu rates, and 19% saturates (table 14.2). the composition of unsaponifiable matter (um) in rice bran oil is listed in table 14.3. rice bran oil (rbo) contains over 4% of um, but peanut oil contains only 0.3% to 1% um [6] .

i want to start a small scale rice bran oil refinery

i will give you medium scale refinery idea land requirment-3acres min capital needed- 1.5–1.75 crores.(exclusive of land lease) installation time-6/8months.

rice bran oil press equipment for high quality, dealers

rice bran oil refining includes continuous dephosphorization and degumming process, physical deacidification and deodorization process, continuous dehydration process, decolorization and filtration process, crystallization and crystal growing process, dewaxing process and electrical control system.t/d rice bran oil production line.

9 surprising benefits of rice bran oil extraction machine

rice bran oil is extracted from rice bran, the outer layer of the rice grain. it’s commonly used as a cooking oil in many asian countries, including, and china.

rice bran oil market size industry share report, 2026

india rice bran oil market size was valued over usd 600 million in 2014 and is likely to be worth more than usd 600 million by 2016. has 1.4 million tons of rbo production potential of which only around 900 kilo tons is only produced. sea is working on plants to help existing mill to upgrade their production process.

scope to boost rice bran oil output, demand: sea -

“based on rice bran potential, rice bran oil production potential is over 1.62 million tonnes per annum,” mehta said, adding that the untapped potential is nearly 6,50,000 tonnes.

rice bran oil suppliers and manufacturers

svr oil was established in the year 1979 by venkatrayudu chowdary who diversified into agri commodities trading and further on into rice bran processing. as a result, today svr oil has become one of the most reputed rice bran oil manufacturers and suppliers.

rice bran oil solvent extraction plant_huatai rice bran

application: the extraction workshop of rice bran oil, to get crude rice bran oil . the production line of rice bran oil extraction machine adopts the type of safe and advanced technology oil processing craft on basis of chemical extraction theory. developed countries make processing of 90% oil by oil solvent extraction process.

rice bran oil extraction plant, rice bran oil production line

rice bran oil production line adopts rice bran expander to make the rice bran into porous expanded pellets, which improves solvent permeability and increases extraction efficiency. adopts negative press evaporating system and mineral oil system, having the features of saving energy and good crude oil quality.

find out correct rice bran oil manufacturing process

rice bran oil manufacturing process. rice bran oil manufacturing process is a complicated oil processing process, like other oil bearing materials, before making oil from rice husk, these rawmaterials should have been fully prepared.rice bran is first screened and then heated by steam at temperature higher than 100 degrees celsius to stop lipase hydrolysis in rice bran prior to extraction.

rice bran oil a gentle oil for younger looking skin

rice bran carrier oil, also called rice bran extract, is derived from the “bran” layer of a grain of rice. bran is hard, brown, and high in oil content. rice bran oil is known for its ability to cleanse, soften, moisturize, soothe, nourish, and smooth the skin. it slows the look of aging and brightens the complexion.

rice bran oil purchasing: manufacturer supplier b2b

rice plant rice grain. rice germ oil (rice oil) is obtained from the rice bran, which is rich in fat, protein and vitamins, which is obtained by peeling the rice grain of the rice plant. rice belongs to the sweet grass family and can be traced back over 7,000 years. a rice plant reaches a height between 50 and 160 cm and forms up to 30 stalks.