best selling vegetable oil extraction process in sri lanka

- Applicable Industries:Food and Beverage Factory

- After-sales Service:Engineer's on-site guidance

- Dimension (L*W*H):1150*1200*1550mm

- Production capacity:100t/d

- Voltage:380V/50HZ/Triple phase

- Weight:1380kg

- Power:4kw

- Advantage:Multifunctional

- Raw material range:cottonseed,pepper seed,sunflower

- Transport Package: Container

- Machine Material:stainless Steel

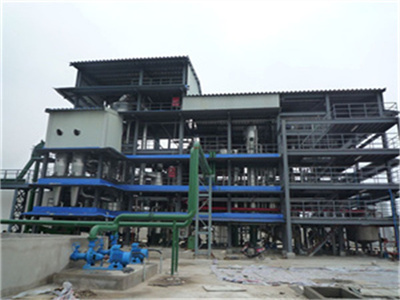

palm kernel rice bran oil extraction plant oil processing machine

an overview of palm oil and palm kernel oil production process vegetable oil processing technology (3)10-1000tpd palm kernel oil processing plant after palm kernel oil extraction process, you can get crude palm kernel oil. it can eat directly or be pumped to palm kernel oil refinery plant for further processing. after palm kernel oil refining

1tph palm oil press production line hottest

warmly welcome clients come to our. 2019-12-31 · 60tpd palm kernel oil extraction plant in ondo,. palm nut cracking and separating machine successfully installed in abidjan,ivory coast. 100tpd palm oil refinery and fractionation plant successfully installed and run. 3tph palm oil press production line.

vegetable oil processing machine

vegetable oil obtained through pressing or extraction contains naturally occurring undesirable impurities that prevent direct use of the oil for food and technical purposes. these impurities can be categorized according to their solubility in oil. the particles insoluble in oil can be pieces of seeds that enter the oil during its processing.

palm oil mill plant edible oil press production line

edible vegetable oil after drying conveying would be sent to crude oil storage tanks. waste oil is recovered by the sand removing system and centrifugal separation. 11.palm kernel oil extraction: palm kernel oil extraction process includes crushing, flaking, steaming and frying, pressing. the production process and equipment is similar to that.

project topic on process for refining vegetable oil and

proect topic: process for refining vegetable oil and its food value includes abstract and chapter one, complete project material available process for refining vegetable oil and its food valuetable of contentschapter oneintroductionchapter two2.1 the oil palm 2.2 extraction and refining of vegetable oil2.3 types and sources of vegetable oil2.4 physical properties and chemical reactions of.

faq edible oil press production line manufacturer

a: we produce oilseeds pretreatment, oil extraction, oil refinery equipment, milling machine and other related grain and oil processing equipment. q:what kind of oilseeds can your equipments process based on our strength r amp d support, we can handle all kinds of the oilseeds, palm fruit, coconut, soybean, rapeseed, cotton seed, sunflower seed.

commercial automatic vegetable oil processing machine oil

commercial automatic vegetable oil processing machine oil extraction machine,sunflower oil extraction machine extracts oil by the pressing of screw shaft. when the sunflower oil press is running, the processed sunflower seeds enter the press chamber from the hopper.

vegetable oil production: industry profile

vegetable oil industry, producing about 75 percent of the domestic supply of vegetable oil. vegetable oils are used almost entirely for human consumption, although small quantities are used for industrial purposes such as in paints, resins, and animal feeds. according to the 1992 census of manufactures, the most

small stainless steel degumming systems

how degumming works water degumming. this relatively simple, cost-effective process removes as much gum as possible in the pre-treatment stage. gums removed here are generally dried to form lecithin, a valuable by-product; however, if preferred, the gums may instead be returned to the meal in the extraction plant.

methods of extraction for vegetable (carrier) oils

methods of extraction for vegetable (carrier) oils. cold pressed or cold expeller pressed: cold pressed oils, also known as cold expeller pressed oils, have been mechanically pressed from the fatty portions of the botanical while ensuring that the maximum temperature (caused by friction) does not exceed 120 degrees.. expeller pressed: expeller pressed oils are mechanically pressed from the.

small stainless steel bleaching systems

the oil bleaching process. typically bleaching is a process which contains oil mixing with bleaching agent followed by separation using filters. upon saturation, the filters shift to regeneration while fresh filters take on the filtration duty. saturated filters contain clay (a bleaching agent) which still has some bleaching power.

how to start a cooking oil mill plant edible oil press

the cooking oil mill plant design contains two parts, process design and non-process design (civil engineering, utility design). as the process design is based on oil mill plant products and production capacity, to select the production processes and production methods, balance materials, configure equipments, and estimate water, electricity and steam consumptions, so the process design is.

ch10 oil press machine

rural vegetable oil production. rural oil extraction usually occurs near the areas of raw material production. this provides the smallscale processor with access to raw materials, helps to ensure that perishable oil crops are processed quickly, and reduces transport costs.deodorisation is essentially a steam distillation process carried.

soybean oil mill plant edible oil press production line

soyabean oil extraction machinery plant soybean oil. 27.08.2016· this complete set of soyabean oil extraction plant which is ordered by one of our client, including equipment for seeds cleaner, cooking, oil expeller, oil filtering. it is turnkey. 3000tpd soybean oil production line/soybean oil mill. 26.07.2017· oil mill plant.

list of vegetable oils

vegetable oils are triglycerides extracted from plants.some of these oils have been part of human culture for millennia. edible vegetable oils are used in food, both in cooking and as supplements.many oils, edible and otherwise, are burned as fuel, such as in oil lamps and as a substitute for petroleum-based fuels.some of the many other uses include wood finishing, oil painting, and skin care

rapeseed oil solvent extraction, rapeseed oil solvent

you can also choose from rapeseed oil solvent extraction, as well as from manufacturing plant, hotels, and farms rapeseed oil solvent extraction, and whether rapeseed oil solvent extraction is 1 year, 2 years, or more than 5 years. there are 395 suppliers who sells rapeseed oil solvent extraction on sale, mainly located in asia.

vegetable oil refining

oil bleaching is a step in the process of crude oil refining. in the bleaching technology, bleaching earth is applied to crude oil, minimizing its content of pigments (e.g., carotenes and chlorophylls), heavy metals, and the phosphorus remaining after degumming. this improves the appearance and taste of the oil.

cooking oil press machine manufacturers

you can also choose from refined, crude, and blended. as well as from cooking, season. and whether cooking oil is glass bottle, bulk, or plastic bottle. there are 8,682 cooking oil suppliers, mainly located in asia. the top supplying country or region is, which supply 100% of cooking oil respectively.

setup small oil mill plant, how to do cost estimation2>

vegetable oil from plants is specifically extracted through mechnical oil pressing or solvent extraction process. in screw oil pressing process, the oil-bearing materials undergo pressing with precision to get the needed oil. with the demand for food grade oil steadily showing significant increase over the years, there are more and more people.

cold pressing rapeseed oil extraction processing plant edible oil

cold pressing oil extraction can keep the physiological active substances contained in rapeseed and avoid harmful substances caused by degeneration of oil, protein, carbohydrate and lipoid in the process of high temperature pressing. rapeseed, especially double-low rapeseed, contains abundant α tocopherol and phytosterol.