bangladesh palm oil press mill process palm oil press mill process

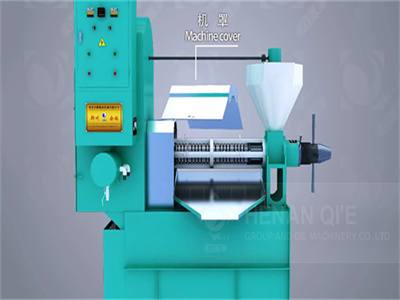

- Applicable Industries:Manufacturing Plant

- After-sales Service:Free spare parts, Video technical support

- Dimension (L*W*H):600*750*1350mm

- Production capacity:10-150 t/24h

- Voltage:440V

- Weight:400kg

- Power:55+11+4kw

- Advantage:High Efficiency

- Raw material range:coconut,mustard,flaxseed

- Transport Package: Fumigated Wooden Box or as Customer′s Request

- Automatic Grade:Semi-automatic

manufacture palm oil mill process,low cost price for sale

digesting and pressing: the purpose of digesting in the palm oil mill process is to separate the pulp and nut and crush the palm pulp. then it is sent to continuous screw press. after pressing of palm oil mill process, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

crude palm oil mill process andythoncianus

a palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. a typical mill has many operational units as shown in figure 2. this comprises of sterilization, stripping, digestion and pressing, clarification, purification, drying and storage.

palm oil mill process palm oil mill machines

palm oil mill processing gathering palm oil pressing, palm oil refining, and palm oil fractionation processing lines, ensures high efficiency and high oil yield of edible palm oil. palm oil pressing machine provides high oil yield crude palm oil making from palm fruit and palm kernel.

cost on setup palm oil processing mill

so, oil palm is the most important crop. setting up a palm oil processing mill would minimize the cost on raw material purchase and transportation. what’s more, has great demand of crude palm oil. it would be very convenient to produce and sell palm oil, which must be a profitable business.

palm oil mill machine palm oil processing machine for edible oil

palm oil mill clarification. 9.palm oil mil process of depericarper (splitter): through floating dry processing the fruit core and fibers separated. fiber and other lighter stuff are blown appearance. 10.palm oil mil process of crushing (crusher): stone cracked open grain separation kernel and shell. in hydrocyclone, the use of kernel and core

automatic palm oil press machine palm oil extraction machine

palm oil press machine details information,we supply best palm oil mill processing plant, palm oil mill plant help customer extract palm oil,offer high technology palm oil extraction machine,palm oil millling machine low investment and hig

palm oil mill screw oil press machine

the quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the ffbs and the process adopted. a palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. the capacity of mill varies between 2.5 150 mt ffb/hr.

3tph palm oil press production line_palm oil mill

this 3tph palm oil press production line was built from february to april, 2024.the whole palm oil press production line includes palm fruit sterilizing machine ,palm fruit threshing machine ,palm fruit digesting pressing machine, crude palm oil clarification machine.now the small palm oil mill plant run well.

3tph palm oil press production line_palm oil mill

this 3tph palm oil press production line was built from february to april, 2024.the whole palm oil press production line includes palm fruit sterilizing machine ,palm fruit threshing machine ,palm fruit digesting pressing machine, crude palm oil clarification machine.now the small palm oil mill plant run well.

crude palm oil mill process -huatai oil machinery

crude palm oil mill process introduction: 1.weighing.palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.loading ramp.ffb after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank. 3.sterilization.

manufacture palm oil mill process machinery,low cost price

palm fruit sterilizing process: palm fruits are very hard and so they have to first be softened before doing anything with them.continuous sterilizer of palm oil mill is major section of palm oil mill process machinery.palm oil mill sterilizer also called palm bunch sterilization machine.we are professional palm oil extraction machine manufacturer.we can product vertical sterilizer or

mill process gopdc

there, the remaining oil is recovered, while palm oil mill effluent (pome) and solid waste are separated. the latter can be used as organic fertilizer in the plantation. palm kernel crushing plant. after digestion of the palm fruit and extraction of the palm oil from the mash, the nuts and fibers are recovered.

palm press process palm oil mill machine leading

small palm oil processing machinery adopts internationally advanced and mature palm oil extraction technology to extract palm oil. it is suitable for small palm oil mill and palm oil production enterprises. more importantly, this palm oil processing machinery has low cost and high productivity.

palm oil mill plant edible oil machinery

the rude palm oil from oil press or solvent extraction plant, which should be refined for better edible oil. palm oil mill capacity: 5-500t/h we are trustable palm oil mill manufacturer in china. we supply complete palm oil mill plants with capacities rages from 5-500t/h. the capacity is normally capacity is less than 30t, directly pressing better.

palm oil milling process linkedin slideshare

a palm oil mill produces crude palm oil and kernels, as primary products and biomass as secondary product. the capacity of mill varies between 60- 100 tons f… slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

palm oil and palm kernel oil extraction process palm oil

5.pressing (extracting the palm oil) palm fruit by stirring and squeeze broken by mashed tank, and then put into the screw press machine to press oil. then, containing sand, water, and oil liquid part put into the purifier separation to get crude palm oil. the press cake (including fiber and nuclear) into the next process.

crude palm oil mill process -huatai oil machinery

crude palm oil mill process introduction: 1.weighing.palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.loading ramp.ffb after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank. 3.sterilization.

palm oil milling process linkedin slideshare

a palm oil mill produces crude palm oil and kernels, as primary products and biomass as secondary product. the capacity of mill varies between 60- 100 tons f… slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

palm oil mill plant edible oil machinery

the rude palm oil from oil press or solvent extraction plant, which should be refined for better edible oil. palm oil mill capacity: 5-500t/h we are trustable palm oil mill manufacturer in china. we supply complete palm oil mill plants with capacities rages from 5-500t/h. the capacity is normally capacity is less than 30t, directly pressing better.

what’s the differences between general oil press and palm

the difference between general oil press and palm press overall little, press main fermentation process should be carried out to kill the cooking stage, palm oil once after precipitation, and filtered to give crude oil, conventional oil after pressing need for secondary crushing, squeezing fully out of oil.

biochar production from palm oil mill residues

biomass (palm oil mill residues) including palm kernel shells (obtained from the crushing of palm nuts in palm oil mill), empty palm fruit bunches (obtained after separating the fruits from sterilized fresh fruit bunches), and oil palm fibers (obtained after the crude palm oil was separated from the sterilized fruit through a screw-press) were

palm oil extraction process, methods, steps agri farming

sterilizer, thresher, palm oil expeller, clarification equipment, palm nut polishing machine. palm oil extraction process: palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. palm oil extracting plant generally begins with the harvesting of the fruit. this is the

palm oil mill processing machine/expeller pressed palm oil

due to the planting structure influence, many africa customer requires small capacity palm oil mill processing machine/expeller pressed palm oil machine, while, in the international market, few

best palm oil processing plant design and construction

supply best palm oil processing plant oil palm is now the most important supplier of vegetable oil in the world. abc machinery can offer you the best customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut.

palm oil milling process linkedin slideshare

a palm oil mill produces crude palm oil and kernels, as primary products and biomass as secondary product. the capacity of mill varies between 60- 100 tons f… slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

palm oil mill plant edible oil machinery

the rude palm oil from oil press or solvent extraction plant, which should be refined for better edible oil. palm oil mill capacity: 5-500t/h we are trustable palm oil mill manufacturer in china. we supply complete palm oil mill plants with capacities rages from 5-500t/h. the capacity is normally capacity is less than 30t, directly pressing better.

what’s the differences between general oil press and palm

the difference between general oil press and palm press overall little, press main fermentation process should be carried out to kill the cooking stage, palm oil once after precipitation, and filtered to give crude oil, conventional oil after pressing need for secondary crushing, squeezing fully out of oil.

palm oil mill processing machine/expeller pressed palm oil

due to the planting structure influence, many africa customer requires small capacity palm oil mill processing machine/expeller pressed palm oil machine, while, in the international market, few

biochar production from palm oil mill residues

biomass (palm oil mill residues) including palm kernel shells (obtained from the crushing of palm nuts in palm oil mill), empty palm fruit bunches (obtained after separating the fruits from sterilized fresh fruit bunches), and oil palm fibers (obtained after the crude palm oil was separated from the sterilized fruit through a screw-press) were

palm oil pressing station palm oil mill machine leading

process flow of palm oil pressing processing line: palm fruits through elevator and conveyors, enters into upper steaming boiler of oil press machine. stirring and heating with steam to destroy the emulsified state forming from oil and water, wherein the coagulation protein denaturation and to reduce the viscosity of the oil for further

double screw palm oil press machine /palm oil mill plant

double screw palm oil press machine is the main equipment to press palm fruit and get palm oil.double screw palm oil press machine is very popular in many countries.double screw palm oil press

best palm oil processing plant design and construction

supply best palm oil processing plant oil palm is now the most important supplier of vegetable oil in the world. abc machinery can offer you the best customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut.