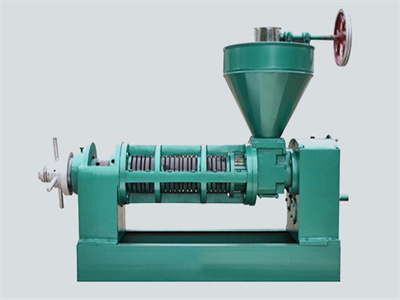

accra the process of pyrolysis oil extraction machine

- Applicable Industries:Retail

- After-sales Service:Video technical support

- Dimension (L*W*H):1320*740*1220mm

- Production capacity:15-25tpd

- Voltage:420V

- Weight:480kg

- Power:90+11+5.5kw

- Advantage:Factory price

- Raw material range:cotton seed,baobab seed,rape seed,soybean

- Transport Package: Export Fumigation-Free Wooden Box

- Function:Making Edible Oil

tyre pyrolysis plant beston group

due to black pollution (waste tyre), a turkish customer ordered a blj-6 tyre pyrolysis plant from beston. this machine has the function of converting tyre to oil. besides, the customer can get some byproducts, like steel wire and carbon black. it was the process of installation. beston engineers possess years of experience and skills.

pyrolysis oil refining plant tyre oil to diesel yangjiang

features of pyrolysis oil refining plant: low cost, recycle one ton used oil need only about 10-20usd; easy to operate, low running cost, it needs only 1-2 workers to operate. can recycle all kinds of used oil. such as black diesel, used engine oil, used machine oil, used rubber oil, almost all industrial oil and waste plastics oil to diesel fuel.

waste tyre pyrolysis plant project report from manufacturer

2.1 tyre pyrolysis process.the steel wires inside of the tyre should be drawn by a wire drawing machine before feeding into the pyrolysis reactor. the steel wire can be recycled in the steelmaking factory and metallurgical plant.waste tyre to oil pyrolysis plant project 3. site layout planning. to do a site layout planning, you need.

what is the process of pyrolysis oil extractionaste

pyrolysis oil extraction machine at present, an oil resource is less and less, but consumption is larger and larger, due to vehicles increases rapidly. otherwise, a large number of waste tire/plastic are discarded every year, it brings heavy environment pollution.

pyrolysis oil turnkey project

it is a professional engineering modern enterprise specializing in various kinds of waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line, essential oil and pigment extraction machine, etc.

waste plastic to fuel oil pyrolysis plant

plastic pyrolysis involves subjecting plastic to high temperature of 400 to 450 degree celsius, in absence of oxygen. in case of oxygen is present plastic will start burning. during pyrolysis plastic breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. pyrolysis is great a way of recycling waste plastics. this plant can also used for waste tire recycling.

pyrolysis oil plant pyrolysis process tyre/plastic to oil

so it could be directly used as asphalt in construction field, like road building. also it could be sold to the asphalt refineries for further refining. another solution is, if you have pyrolysis plant, you could put the distillation residues to the pyrolysis machine for further processing, thus to make fully oil extraction.

advanced pyrolysis plant for sale moregreen

the moregreen pyrolysis plant decomposes waste into oil vapor by high-temperature pyrolysis technology. then the oil vapor enters the cooling system through the oil-gas separator, wherein the oil flows to the oil tank, and the pyrolysis gas passes through water seal to the gas recovery system to become the main furnace fuel.

starting a tyre recycling business with a tyre pyrolysis plant

tyre pyrolysis plants make use of the pyrolysis process to transform waste tyres into useful products which have popular in particular industries. simply speaking, investing in a pyrolysis plant permits you to set up a profitable business that does not only makes good money but will help with tackling a major environmental problem.

tyre2oil tyre to oil machine for extracting oil

we are leading exporters of pyrolysis plant. infogate with its unique renewable technology has come up with a concept of setting new standard in renewable energy that includes using of waste tyres as a raw material and producing green fuel oil, carbon black, steel and gas. infogate limited 1109, 11/f, kowloon centre 33 ashley road, tsimshatsui

plastic pyrolysis oil to diesel distillation plant

the main working process of plastic pyrolysis oil to diesel distillation plant. as can be seen from the main process above, the operation of plastic pyrolysis oil to diesel distillation plant is relatively simple, and there will be no secondary pollution in the process of processing plastic pyrolysis oil.

how to deal with the problems occurred in the pyrolysis

nowadays, with the increasing of people’s awareness in the environmental protection, pyrolysis plants are becoming more and more popular among the industries. as for pyrolysis equipment, it mainly uses some living waste and industrial rubbish as the raw materials, such as waste tire, waste plastic, medical waste, oil sludge and so on.

waste tyre/plastic pyrolysis oil distillation plant

through pyrolysis process, we can effectively convert waste tyre/plastic into useful resources-fuel oil, which has a wide range of applications. but in order to make the fuel oil have wider applications and higher values, we can further process the fuel oil by using the waste oil to diesel plant .

waste tire to fuel oil pyrolysis plant huayin

tire pyrolysis involves subjecting tire to high temperature of 400 to 450 degree celsius, in absence of oxygen. in case of oxygen is present plastic will start burning. during pyrolysis tire breaks down into smaller molecules of pyrolysis oil, pyrolysis gas, steel wire and carbon black. pyrolysis is a great way of recycling large amounts of tires.

waste tire pyrolysis machine

we company is a professional engineering modern enterprise specializing in various kinds of vegetable oil, animal and fish oil production line, waste engine oil regeneration line, biodiesel production line, waste tires, plastics and rubbers pyrolysis line, essential oil and pigment extraction machine, has engineering design, equipment manufacture, technology research.

pyrolysis oil machinery supplier

the waste tyre/plastic pyrolysis plant can convert the waste tyre/plastic waste to energy, such as tyre/plastic pyrolysis oil, carbon black and combustible gas. those products are popular in the market, and they also have a great market value.

tyre pyrolysis oil plant in beston machinery : u

egg carton machine for sale customized molds beston. tyre pyrolysis plant in the beston machinery ... machinery. tire pyrolysis recycling plant beston group. plastic to oil plant in dominica beston machinery. tyre pyrolysis oil plant in beston machinery ... what is tyre pyrolysispyrolysis process of waste.

batch tyre /plastic pyrolysis technology process

batch pyrolysis plant by this type of machine, workers should fill the raw material, for example, the waste tyre, plastic with a batch of raw material and take the process, and then after cooling down and removal of the carbon, the next process will happen.

plastic pyrolysis plant pyrolysis oil making machine

find here plastic pyrolysis plant, pyrolysis oil making machine manufacturers, suppliers exporters. get contact details address of companies manufacturing and supplying plastic pyrolysis plant, pyrolysis oil making machine across.

oil sludge pyrolysis plant crude oil sludge treatment

1. pyrolysis oil (12.5%): with large potential to be a kind of fuel. you can use beston distillation plant for sale to get qualified oil from it or just sell it out at a considerable price. 2. sand (72.5%): can be used to produce bricks. 3. water(15%) how to choose a high-quality oil sludge recycling plant