ndola soybean oil refining detailed soybean oil refining process

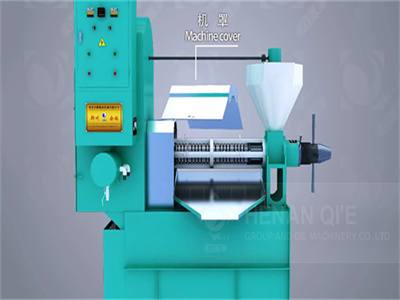

- Applicable Industries:Food and Beverage Shops

- After-sales Service:7*24 Hours Online Service

- Dimension (L*W*H):2250*1700*1700mm

- Production capacity:140 kg per hour

- Voltage:110V/220V/380V

- Weight:950kg

- Power:22kw (4 Poles)

- Advantage:High Output

- Raw material range:sunflower seed,tea seed,olive,peanut,grape pip

- Transport Package: Wooden Case

- Press type:Hot Press Oil Machine

soybean oil refining detailed soybean oil refining process

soybean oil refining. the crude soybean oil still contains many oil-insoluble and oil-soluble impurities that needs to be removed. soybean oil refining including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter and gums) and bleaching (with activated earth or activated carbon to remove colour and other.

step by step soybean oil refining process hope my worlds

soybean oil is the furthermost consumed edible oil in the world. many companies in the world manufacture this edible oil. as we consume tons of soybean oil over the year, we all should know the soybean oil refining process. the demand for soybean oil is so high. it has 20% fat and enriched with a lot of protein.

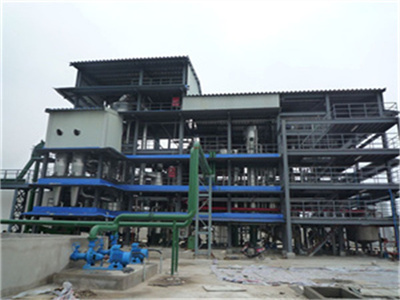

soybean oil refining processing plant soybean oil refinery plant

deodorization section of soybean oil refining process. deodorization of bleached and filtered soybean oil is done to remove the highly volatile compounds, mainly free fatty acids, aldehydes and ketones which causes odor and smell in degummed and bleached soybean oil. deodorization of oil is done under high vacuum and at high temperature (180.

cooking crude oil refining machine refined machine soybean

refining process of soybean edible oil expeller machinery. crude oil generally refers to oils and fats which are extracted from plant oils from leaching or pressing processes,which contain some undesirable (or industrial) impurities.the main component of crude oil is a mixture of triglycerides (commonly known as neutral oil).in addition to neutral oil, the crude oil also contains non.

what is soybean oil refining processch

advanced techniques applied soybean oil refining production line with high efficiency and low residual oil.henan doing comapny is focusing on designing physical and chemical edible oil refining process through de-mixed, degumming, dehydration, deacidification, decoloration, dewax and deodorization, oil pumps, filter system to obtain high purity refined soybean oil.

set up a soybean oil refinery plant with low cost

2. the deacidification (neutralization) process in soybean oil refining process: in batch type soybean oil refinery plant, free fatty acids are neutralized by using alkali, and then are converted into soap stock. at the same time, additional impurities are also removed by soap stock adsorption.

refining process of soybean edible oil expeller machinery

refining process of soybean.1.method of oil refining. according to the operation characteristics and the raw materials selected, the method of oil refining can be roughly divided into three methods: mechanical method, chemical method and physical chemistry method. in general, it is necessary to precipitate the crude oil first.

high efficiency soybean oil refining machine price

soybean oil refinery machine. cold hot oil press machine soybean oil making line sunflower oil extraction plant oil refining process; chat online; get price; 1-10tpd batch type soybean oil refinery machine. henan company is the best soybean oil refinery machine manufacturer and supplier in china, with a wealth of experience in edible seed oil production field.

new-technology crude oil refining plant soybean

provide professional soybean oil refining technology. soybean oil refining methods. soybean oil processing needs a lot of professional techniques, soybean oil extraction, refining are the most important process in the soybean oil plant.crude soybean oil is typically shipped for refining to establishments engaged in the production of edible / vegetable oils, shortening, and margarine.

soyabean oil refinery plant, soyabean oil refinery

soyabean oil refinery by tinytech comes in various capacities ranging from entry level small scale plant of 5-tpd to medium and big scale plants upto 30-tpd. we are leading manufacturers and exporters of soyabean oil refinery plant systems for processing the crude soya oil into the refined soya oil.

5tpd soybean oil refining line crude palm oil from oman

soybean oil refining detailed soybean oil refining process. soybean oil refining. the crude soybean oil still contains many oil-insoluble and oil-soluble impurities that needs to be removed. soybean oil refining including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids.

chapter 7

caustic refining process soybean oil can be refined by either a batch or a con tinuous process. essentially all soybean oil in the united states is now refined by the continuous process. crude soy bean oil is supplied to the caustic refining process from storage or direct from the oil dryer in the solvent extraction plant (chapter 4).

alkali refining oil chemists&039; society

4.1. neutralisation of crude oil. this method has become established mainly in the for refining soybean oil, the so called long mix process. the process is a combination of degumming and neutralization. for the conditioning of the nonhydratable phosphatides, a small quantity of phosphoric or citric acid is added to the crude non-degummed oil.

what is soybean oil refinery processegetable oil

soybean oil is a vegetable oil extracted from the seeds of the soybean (glycine max). it is one of the most widely consumed cooking oils. to produce soybean oil, the soybeans are cracked, adjusted for moisture content, heated to between 60 and 88 °c (140–190 °f), rolled into flakes, and solvent-extracted with hexanes.

soybean and palm oil refining business

soybean and palm oil refining business. refining of crude soya bean and palm oil. opportunities in edible oil industry soybean oil is one of the most important edible oil used.

effect of refining process and use of natural antioxidants

effect of refining process and use of natural antioxidants on soybean oil luis ángel medina-juárez and nohemí gámez-meza departamento de investigaciones ci entíficas y tecnológicas de la universidad de sonora méxico 1. introduction soybean (glycine max l. merril.) is an annual plant of asian origin, adapted to temperate climates.

soybean oil production line, soybean oil extraction plant

1. superfine fragrant soybean oil refining process. this workshop adopts the production technology of batch refining. according to the type and quality of the crude oil, the process parameters are adjusted and different refining methods are selected to produce the first and third-grade oils. the process equipment we provide has the following.

soybean oil refining production line process edible oil

soybean oil refining process: 1. hydration degumming alkali refining deacidification process neutralization: the crude oil is output by the oil feed pump from the oil tank, and enters the crude oil heat exchanger to recover part of heat after metering and then is heated to the required temperature by the heater.

high quality soybean oil processing machine for sale

the three types of soybean oil refinery plant. soybean oil refining process includes degumming, deacidification, decolorization/bleaching and deodorization. through these process, the gums, acid, pigment and bad smell in the crude oil are all removed. the detailed soybean oil processing plant project program and quotation, please contact doing.

degumming, refining and bleaching soybean oil springerlink

refining, as a specific process, deals primarily with free fatty acid removal, with or without simultaneous degumming as a single-step operation. state-of-the-art wet, chemical refining practices are described, and the current limitations and future opportunities for the physical refining of soybean oil are discussed.