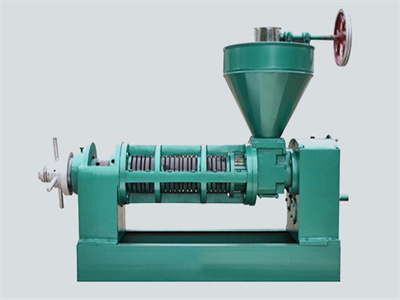

cape town 1-10ton day cottonseed oil extraction machine plant

- Applicable Industries:Manufacturing Plant, Farms

- After-sales Service:Provide Longlife Technical Support

- Dimension (L*W*H):1640*700*1200mm

- Production capacity:1t/d

- Voltage:110V/220V/380V

- Weight:650kg

- Power:52kw

- Advantage:Top brand

- Raw material range:rice bran,peanut,peanut,baobab seed,corn germ

- Transport Package: Wooden Box

- CE Certificate:Yes

1-10 ton crude palm oil refinery plant for oil

for mini palm oil mill plant with 1~10 ton per day production output, the processing flow is relatively simple, including threshing, digesting and sterilizing, oil pressing and oil filtering. one of the reasons why small scale palm oil mill are very common in the global market including and is that they are affordable and they

cottonseed oil mill / oil extraction plant manufacturers

our cotton seed oil extraction plant are well-known for its quality, long-lasting durable.edible oil extraction machine. cotton seed contains 18 20 % oil content. the cottonseed can be processed without delinting in the oil expeller machine. in a single pressing 12 14 % oil will be obtained and in the oilcake is still about 6.0 7.5.

complete equipment and machinery for cottonseed oil mill plant

cottonseed oil pressing / expelling (by using mechanical screw type oil press); cottonseeds can be pre-pressed before they get sent directly to the refinery plant. to handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil. the machine used for the job has a large capacity and its cake leaves less residual, which makes.

cottonseed oil extraction machine/cottonseed oil mill

cottonseed oil extraction machine/cottonseed oil mill machinery. time online:2024-11-02 13:07. product description: cottonseed oil making process usually uses cottonseed oil press machine, cottonseed oil extraction machine and cottonseed oil refining machine.

cottonseed oil extraction process plant equipment

cottonseed oil extraction process plant refining process of cotton processing equipment; degumming and deacidification: the gumming is moved by phosphoric acid and hot water. there are two ways to move the acid in the edible oil. one is chemical way, the other one is physical way. the chemical way is using naoh to react with acid.

edible oil extraction machinery/oil press

best edible oil extraction machine manufacturer supplier. about doing. doing holdings henan glory oil fats engineering co., ltd is a large-scale oil mill machinery manufacturing enterprice integrating r d,design, manufacture and installation.we are specialized in peanut oil extraction machine, soybean oil extraction, corn germ oil extraction machine, cottonseed oil extraction machine.

cottonseed oil extraction plant

for the small cottonseed oil extraction plant, pls confirm the capacity you need, i mean how many tons cottonseeds you want to press per dayr the small capacity, you can choose from 1-3tpd,5-6tpd,8-10tpd,15tpd, etc, then i can recommend you the suitable machines.

oil extraction machine cottonseed oil press expeller

our company was founded in 1992. it is an internationally renowned manufacturer and exporter of edible oil machinery, producing and selling all types of oil extraction machinery and spare parts required for the production of oil extraction plants, oil mill, oil refineries and biodiesel plants.the company delivers the top level solutions to clients for every aspect of machinery.

cottonseed oil extraction machine/cottonseed oil mill

cottonseed oil extraction process: cottonseed oil extraction production line get crude extraction oil from cottonseed cake through processing flows of solvent extracting, mixture oil filtration, wet bran treatment of dephenolizaiton and mechanical desolvent, and low temperature drying, evaporation, gas stripper to obtain crude cottonseed oil.

large capacity coconut oil extraction machine

we manufacture and exporter of coconut oil extraction machinewhich is specially designed to be used for coconut, copra.this coconut oil extraction machine can crush coconut,copra seed.moreover the coconut oil extraction machine can crush ground nut, linseeds, mustard seeds, palm kernels, seeds, castor, neem, sun flower seeds.

cottonseed small capacity oil press machine

cottonseed oil is cooking oil from the seeds of cotton plants of various species, mainly gossypium hirsutum and gossypium herbaceum, that are grown for cotton fiber, animal feed, and oil.. cotton seed has a similar structure to other oilseeds such as sunflower seed, having an oil-bearing kernel surrounded by a hard outer hull; in processing, the oil is extracted from the kernel.

manufacturer sale cottonseed oil extraction plant

cottonseed oil refinery of cottonseed oil extrction plant: after getting crude cottonseed oil from pretreatment section and extraction section, crude cottonseed oil enters refinery section. there are three main parts in cottonseed oil refinery plant. . a. deacidification part: it is used to move the acid in the crude oil. b. decolorization part: the white clay is used to move the color of the.

cottonseed oil extraction plant for sale and high quality

cottonseed pretreatment machines. the cottonseed oil extraction workshop of cottonseed oil extraction plant: the advantage of cottonseed oil solvent extraction is to get as much as oil from cottonseeds. when extracting cottonseed oil by solvent, the oil residues will be less than 1%. there are four main parts in cottonseed oil extraction.

cottonseed oil processing machine edible oil extraction

complete set cottonseed oil processing machine are generally divided into three processes, they are: cottonseed oil pretreatment and pre-pressing machine, cottonseed oil solvent extraction plant and cottonseed oil refinery plant.here we focus on introduction the cottonseed oil processing process, which from cottonseeds to crude cottonseed oil and refined cottonseed oil.

5tpd palm oil physical refinery plant_palm

the palm oil refinery plant project uses a physical refining method to process palm oil, which has low production cost, high efficiency, and simple production process.5tpd palm oil physical refinery plant not only used to refine palm oil and palm kernel oil, but also used to refine soybean oil, peanut oil, sunflower oil, cottonseed oil the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.

cotton seeds oil refinery plants oil refining machine

oil refining machine is used for producing the first or second-grade edible oil. we are able to supply the professional oil refining plant and related oil refining equipment. with the high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in large.

manufacturering cooking oil making machine, edible oil

pretreatment and pressing plant. pretreatment is to adjust oil seeds into best state before pressing or solvent extraction. mainly includes cleaning, crushing, softening, flaking, puffing, cooking, drying, etc. different oil seeds need different pretreatment process, and then use oil press machine to get oil out.

cottonseed oil solvent extraction plant

cottonseed oil solvent extraction plant is the second step in cooking oil making machine .product (cake from cooking oil press section) is carried into solvent extraction palnt.there are still much oil in cake.cottonseed oil solvent extraction plant is the machine to extract oil from oil cake which can ensure the residual oil rate is less than 1%.

buy suitable cooking oil machine for starting your small

cooking oil production plant (1-10ton/d) main equipment : seeds screening and cleaning equipment, screw elevator, cooker, oil expeller, oil filter and electric cabinet. price : the cost is varified according to production output, oil making process design, and selection of each equipment.

steps of cottonseed oil processing process

within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. cottonseed meal is a good source of protein. it is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.