professional soybean oil refining process in kenya

- Applicable Industries:Food Shop

- After-sales Service:Free spare parts

- Dimension (L*W*H):8000*2500*1370mm

- Production capacity:80t/d

- Voltage:380V/50HZ

- Weight:330kg

- Power:11-15kw

- Advantage:High Oil Yield

- Raw material range:macadamia nuts,black seed,soybean

- Transport Package: Container

- Condition:New

soybean oil refining processing plant soybean oil refinery plant

deodorization section of soybean oil refining process. deodorization of bleached and filtered soybean oil is done to remove the highly volatile compounds, mainly free fatty acids, aldehydes and ketones which causes odor and smell in degummed and bleached soybean oil. deodorization of oil is done under high vacuum and at high temperature (180.

set up a soybean oil refinery plant with low cost

next, you should learn about the soybean oil refining process. the following picture is the soybean oil refining process flow chart that is made based on our engineers&039; design. soybean oil refining process flow chart. 1. the degumming process in soybean oil refining process: soybean oil has high gums content.

provide professional soybean oil refining technology

soybean oil processing needs a lot of professional techniques, soybean oil extraction, refining are the most important process in the soybean oil plant.crude soybean oil is typically shipped for refining to establishments engaged in the production of edible / vegetable oils, shortening, and margarine. crude soybean oils contain small amounts of.

most advanced crude oil refinery plant peanut palm

high efficiency cooking soybean oil refinery machine phonemania.nl. the oil refinery equipment is a complete set of edible oil refinery,which also apply to various of crude oil like palm oil,rice bran oil,cottonseed oil,flaxseed oil,soybean oil,etc.it adopts the batch-type oil refinery process and advanced edibl . get price

soybean oil refining detailed soybean oil refining process

in the u.s.a. and in europe, for soybean oil refining, the caustic soybean oil refining process is by far the most used. the physical refining of palm oil, lauric oils and other fats and oils that have a low phosphatide content by dry degumming and bleaching followed by distillation, deodorization, is 20 to 25 years old and common practice today.

cooking crude oil refining machine refined machine soybean

refining process of soybean edible oil expeller machinery. crude oil generally refers to oils and fats which are extracted from plant oils from leaching or pressing processes,which contain some undesirable (or industrial) impurities.the main component of crude oil is a mixture of triglycerides (commonly known as neutral oil).in addition to neutral oil, the crude oil also contains non.

edible oil refinery machine technology myande group

the process is suitable for refining soybean oil, rapeseed oil, sunflower oil, palm oil and etc. 1. degumming the purpose of degumming is to remove impurities such as phospholipids, gums, proteins and etc. there are several methods as follows: water degumming, acid degumming, special degumming and etc. 2. neutralizing

soyabean oil refinery plant, soyabean oil refinery

soyabean oil refinery by tinytech comes in various capacities ranging from entry level small scale plant of 5-tpd to medium and big scale plants upto 30-tpd. we are leading manufacturers and exporters of soyabean oil refinery plant systems for processing the crude soya oil into the refined soya oil.

soybean oil refining machinery find oil refinery

application: high efficiency oil refining from soybean oil, cottonseed oil, rapeseed oil, avocado oil, corn germ oil, rice bran oil, sunflower oil etc. we assure the most precise design, high quality soybean oil refining machine, mature project installation, and perfect after sale services.

small stainless steel neutralization systems

global service and support optimize edible oil refining processes. more than 130 years of experience. experts the world over. service centres in nearly 100 countries. to maximize quality, efficiency and yield of your processes, take advantage of the alfa laval global service network with local service centres and partners in worldwide.. no other process system supplier can provide the depth.

supply soybean peanut sunflower palm oil press machine

different edible oil refinery plant has different functions, they can refine different kinds crude oil into refined edible oil. doing company provide different solutions to set up all kinds of edible oil refinery plant, such as palm oil refinery plant, soybean oil refinery plant, sunflower oil refinery plant, peanut oil refinery plant, etc.

what is soybean oil refinery processegetable oil

professional designed soybean oil refinery process line assures high soybean oil capacity. the application of auto welding machine, professional designed thermometer, press gauge, safety valve, and vacuum system ensure the most secured refining of crude soybean oil with low residual oil and low pollution.

professional soybean oil manufacturing process

kmec is the expert of soybean oil processing.we offer state of the art soybean oil manufacturing process to all of our clients,we manufacture and export variety of oil processing equipment and complete soybean oil plant.. the soybean oil manufacturing process is a not a simple process. there are some necessary steps that you should follow.

10-20ton per day vegetable oil processing machine

9.11.1.2 process description6-9 the following process description discusses only soybean oil manufacture, because emission factors are available only for that activity. corn, cottonseed, and peanut oil processing are similar to soybean processing, except for differences in the soybean preparation for oil extraction. the process

processing of soybean oil for food uses usda

refining step to increase the efficiency of phosphatide removal during caustic refining (ii). oil refining is usually a continuous process. a is to 20% sodium hydroxide solution. based on the free fatty acid content of the oil plus 0.10-0.13%excess, is proportioned into the crudeoil, mixed in a high shearin-line mixer. and then held for 3 to is.

edible oil processing technology pdf industry news

vegetable oil refining plant is removing of unwanted substances from the vegetable oil and fat oil and make them valuable for use. it is carried out in four phases: first is degumming process , second is deacidifation process, third is continuous bleaching process and fourth is deodorization process.

soybean oil processing byproducts and their utilization

refining of soybean oil to make a neutral, bland-flavored, and light-colored oil results in several byproducts. fig. 17.1 diagrams the conventional refining process and shows the byproducts that are generated at each stage. download : download full-size image; fig. 17.1. processing diagram for soybean oil.

edible oil refining processing line

we can provide turnkey oil refining solution with capacities from 1-20t/d. our cooking oil refining plant is used to process various kinds of oilseeds such as peanuts, sunflower, soybean, rapeseed, etc. and our cooking oil refining plant capacity can be customized.

edible oil full continuous refining processing equipment

200tpd soybean oil production projectedible oil refining refining process can be divided into chemical refining and physical refining. it can remove phospholipid, ffa, pigment, off-flavor and other impurities. it includes the following sections:degumming, deacidifying, bleaching, deodorization and dewaxing..

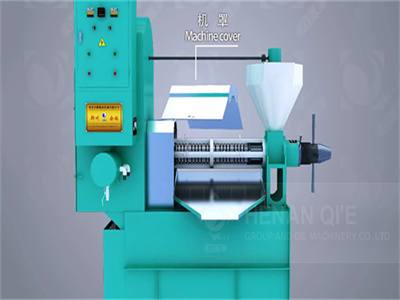

sesame oil press edible oil press oil refinery machine

high quality supplier of oil extractor. we offer top quality edible oil press, oil refining plants, oil filling and packing machine and complete oil production line for soybean, peanut, sesame seeds, sunflowers seeds,palm kernel, coconut, corn germ and so on.