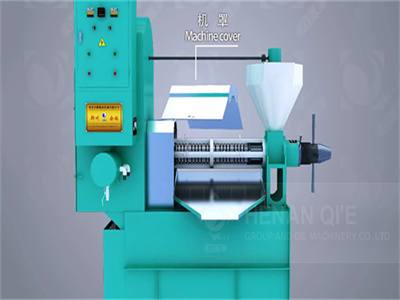

kampala edible oil continuous extraction unit products from artisan

- Applicable Industries:Manufacturing Plant, Farms

- After-sales Service:Video technical support, Online support

- Dimension (L*W*H):1700*1600*1750mm

- Production capacity:9-11t/d

- Voltage:380V/220V

- Weight:610 kg

- Power:30+5.5+3kw

- Advantage:Multifunctional

- Raw material range:rice bran,black seed,walnut

- Transport Package: Wooden Case

- Machine Material:stainless Steel

edible oils process solutions artisan industries

artisan’s edible oil process solutions optimize the distillation and purification stages of your process without adding significant operational costs. with our solvent recovery solution, this helps customers save money by recycling waste and transferring heat more efficiently.

edible oils oil seed processing continuous solvent

manufacturer of edible oils oil seed processing continuous solvent extraction plants, continuous vegetable oil bleaching section, edible oils oil seed processing plant and oil expeller machines for cotton seeds and shea nuts and sunflower.

edible oil mill machinery, oil extraction machinery

company profile having experience of years, we are an iso 9001-2008 approved company with ce and atex certifications providing complete project management services to il seed processing, solvent extraction edible oil refining, fractionation related product industries.

mustard oil extraction process is important price list

factory offers 477 coconut oil machine price products. about 14% of these are oil pressers, 15% are separation equipment, and 1% are filling machines.cottonseed edible cooking oil making process from.gemco provides a series of cooking oil making machine line that is neccessary for any oil mill or oil extraction.

extraction process edible oil production

extraction process. oil extraction process is related to extraction of the liquid element in a matter and connected with hard-liquid extraction. at this process, oil is separated of seed with using the hexane. after this operation, oil is transferring from oil- solvent mixture with the distillation of solvent under the vacuum.

preparation process edible oil production

the covers of the oiled-seed cracked in the previous stage are separated from the seed by cover separator. separating the covers from the seed helps for an easier pressing and also shortens the washing-time of oiled-cake in extraction unit. besides that, the protein availability in the oiled-cake is increased by means of this cover separation.

best edible oil extraction machine manufacturer supplier

about we company is a large-scale oil mill machinery manufacturing enterprice integrating r d,design, manufacture and installation.we are specialized in peanut oil extraction machine, soybean oil extraction, corn germ oil extraction machine, cottonseed oil extraction machine, rapeseed oil extraction machine, sunflower oil extraction.

edible oil fat refining ips engineering

concerning yield, the oil retention, depends on type of oil, bleaching agent and can be up to 50 wt % on bleaching earths and nearly 100 wt % on activated carbon. the spent cake can be deoiled in solvent extraction unit to reduce the above values below 5%. bleaching . pretreated oil silica bleaching agent a bleaching agent b

shree ganesh edibles pvt. ltd

shree ganesh group is a leading group in food grian and edible oil processing company in the northern region of with a group turn over of 500 crores. the group started its beginning in 1975 as “varinder kumar company” in food grain business.

edible oils and fats refining gianazza

the oil, it is actually a refining step that removes many impurities, mainly soaps remained in the oil after alkali refining and phosphatides. fully continuous plants are available for capacities of 25 t/d upwards: the operation is rigorously continuous in the bleaching step proper, while filtration is semi-continuous in the sense that there

complete oil mill business plan top 10 steps

start successful edible oil mill business. here is a brief project report of 5ton/day edible oil mill setup in manipur,. this project is a small scale complete oil production including oil pressing and oil refining process, designed and built for processing mustard seeds.

mittaloils.in mittal agro oil industries

their oil cake brand mcf is one of the leading oil cake brand in haryana. continuing with this spirit and zeal his sons added flavor to the expanding business. their continued vision to rise brought to the fore “mittal agro oil industries” the 150 mt tpd state of art continuous processing edible oil refining and vanaspati plant.

continuous dewaxing filtration plant manufacturers mumbai

continuous solvent extraction plant cap 250 tons per day processing cake 200 tpd for soyabean 200 tpd mesh gum. and refinery for 50 tons per day of crude cottonseed. 49: global refinery pvt ltd. rajkot continuous vegetable oil refinery plant of capacity 50 tpd soybean oil. .

manufacturer, supplier of continuous peanut oil refining

continuous peanut oil refining machine 3d diagram. henan doing company is a leading designer, manufacturer and exporter of edible oil refinery plant in both continuous type vegetable oil refinery plant and batch type vegetable oil refinery plant. next you will see the continuous peanut oil refining process.

sundex continuous refining line sundex continuous

the refining process has been explained under the heading vegetable oil refining. sundex process engineers pvt. ltd offers chemicalâ continuous refining plants.the word chemical refining appears since caustic soda a chemical is used in refining of vegetable oils.

find natural cold oil press,double screw expeller oil

product categories of oil press, we are specialized manufacturers from china, natural cold oil press, double screw expeller oil press suppliers/factory, wholesale high-quality products of screw oil press r d and manufacturing, we have the perfect after-sales service and technical support. look forward to your cooperation!

oilseed processing anderson international corp

anderson international corp has been supporting complete oilseed milling systems for over a century. in 1900, our founder, valerius d. anderson, invented the first continuous mechanical screw press the expeller®. it was a revolutionary new method for the continuous recovery of edible oil from oilseeds. since then, anderson international corp has designed, manufactured,…

turnkey edible oil extraction machine myande group

the continuous solvent extraction is the most modern way of recovering oil from oil seeds, beans and other oil, grease containing products. in comparison with the rest of oil extraction processes, the continuous solvent extraction provides such advantages (economy in labor, higher oil yield, reduced maintenance) that it becomes a “must” for.

edible oil processing, 2nd edition wiley

7.2 enzyme applications before oil refining 199. 7.2.1 enzyme-assisted pressing 199. 7.2.2 enzymatic degumming 200. 7.2.3 enzymatic degumming process (phospholipase a1) 202. 7.2.4 other phospholipases 205. 7.2.5 oil recovery from gums 205. 7.2.6 oil remediation 206. 7.3 applications within edible oil modification 208

continuous bleacher manufacturer,continuous bleacher

product description. we hold expertise in manufacturing, exporting and supplying highly efficient continuous bleacher.it is manufactured with high precision using high grade components and innovative technology by our dexterous professionals and is available in different technical specifications to meet the diverse requirements of the clients.