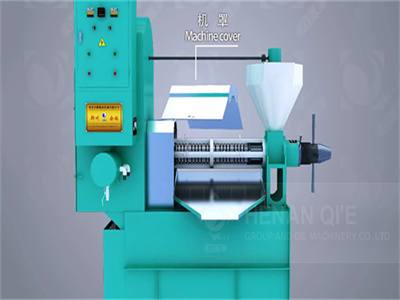

good quality palm kernel oil refining machine in zimbabwe

- Applicable Industries:Food Shop

- After-sales Service:Service Machinery Overseas

- Dimension (L*W*H):8000*2500*1370mm

- Production capacity:10-30 ton/day

- Voltage:440V

- Weight:850kg

- Power:5kw

- Advantage:High Oil Yield Efficiency

- Raw material range:soybean,rapeseed,shea nut,black seed,rice bran

- Transport Package: Container

- CE Certificate:Yes

palm kernel oil refining process/crude oil refining machine

manufacturing palm kernel oil refining process/crude oil refining machine,the purpose of palm kernel oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces.

good quality competitive price peanut oil expeller palm

good quality competitive price peanut oil expeller palm kernel oil refinery machine , find complete details about good quality competitive price peanut oil expeller palm kernel oil refinery machine,peanut oil expeller,palm kernel oil,oil refinery machine from oil pressers supplier or manufacturer.

palm kernel oil refining process

palm oil refining classification is based on different uses and requirements, the use of physical methods and chemical processes, removal of crude palm oil harmful impurities and unnecessary substances, get some standard oil. we are professional manufacturer of palm kernel oil refining machine. zhengzhou qi'e grain oil machinery co., ltd will

palm kernel oil refining processing machinery find edible

palm kernel oil refining processing line adopts advanced and scientific physical refining and totally stainless steel tank refining. palm kernel oil is non-drying oil with low gum content, which is suitable for physical refinery. fatty acid composes of 45%-51% lauric acid and 13%-25% cardamom acid. palm kernel oil contains soap grade and food

factory supply 2tph palm oil processing machine

palm oil processing 3. 1 general processing description. research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

palm oil refining processing plant palm oil refinery plant goyum

palm oil is used widely for cooking due to its heat resistant property as compared to any other vegetable oil. the unique and best quality of palm is that it produces two types of oil: palm oil and palm kernel oil. palm oil is extract from the flesh of the palm fruit and palm kernel oil is extract from the seeds or kernel of the palm fruit

professional palm oil processing machine, palm oil refining

we have three kinds of palm/ palm kernel oil refining machine can be choosed: batch type palm oil refining machine suitable for small capacity like 1-2-3-5-10tpd; semi-continuous palm oil refining machine suitable for medium capacity like 10-30tpd; full-continuous palm oil refining machine suitable for bigger capacity over 30tpd.

palm kernel oil refining process palm oil extraction machine

palm kernel oil refining process is a extremely complicated process.palm kernel oil refining process consists of palm kernel oil degumming process.palm kernel oil deacidification process,palm kernel oil decolorization process and palm kernel oil deodorization process.and our palm kernel oil refining machine is widely used in peanut oil refining ,soybean oil refining,corn germ oil refining

how to refine palm kernel oil leading manufacturer supplier

alkali neutralization; adds the mixture of liquid caustic soda (1.5% of crude palm kernel oil weight and with 160 baume) and the liquid sodium salt (0.5% of the crude palm kernel weight) into the crude palm kernel oil, then stir it rapidly at the speed of 60 r/min for about 10 to 15 minutes, and followed by the stirring slowly at the speed of 27 r/min for 40 minutes.

palm kernel oil refining processing machinery find edible

palm kernel oil refining processing line adopts advanced and scientific physical refining and totally stainless steel tank refining. palm kernel oil is non-drying oil with low gum content, which is suitable for physical refinery. fatty acid composes of 45%-51% lauric acid and 13%-25% cardamom acid. palm kernel oil contains soap grade and food

factory supply 2tph palm oil processing machine

palm oil processing 3. 1 general processing description. research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

palm oil refining processing plant palm oil refinery plant goyum

palm oil is used widely for cooking due to its heat resistant property as compared to any other vegetable oil. the unique and best quality of palm is that it produces two types of oil: palm oil and palm kernel oil. palm oil is extract from the flesh of the palm fruit and palm kernel oil is extract from the seeds or kernel of the palm fruit

good price 1thd 2tpd 5tpd 10tpd palm kernel oil extraction

good price 1thd 2tpd 5tpd 10tpd palm kernel oil extraction machine palm kernel oil pressing machine , find complete details about good price 1thd 2tpd 5tpd 10tpd palm kernel oil extraction machine palm kernel oil pressing machine,palm kernel oil expeller,palm kernel expeller machine,palm kernel oil expeller price from oil pressers supplier or manufacturer-henan doing environmental protection

palm kernel oil business

depending on your financial capacity, it can be run in a small, medium and large scale palm kernel oil mill plant. but the first problem coming to your mind may be where i can get palm kernel oil machinery (say palm kernel oil pressing machine, palm kernel oil processing unit, palm kernel oil refinery plant etc.) in good qualityp>

palm oil refining processing plant palm oil refinery plant goyum

palm oil is used widely for cooking due to its heat resistant property as compared to any other vegetable oil. the unique and best quality of palm is that it produces two types of oil: palm oil and palm kernel oil. palm oil is extract from the flesh of the palm fruit and palm kernel oil is extract from the seeds or kernel of the palm fruit

factory supply 2tph palm oil processing machine

palm oil processing 3. 1 general processing description. research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

physical and chemical process in palm oil refining plant

the palm oil and palm kernel oil are steamed at a temperature of 240°c to 260°c to get away the odors and tastes, and then they are cooled into room temperature (about 55°c) for further use. this process have great impact on the quality of the final palm oil and palm kernel oil.

1-20tpd palm kernel oil refining process line for sale

the refined palm kernel oil has high quality and is good for long time storage. the 1-20t/d palm kernel oil refining process line is suitable for rapeseed oil, cotton seed oil, soybean oil, peanut oil, etc. palm kernel oil refining process flow chart. advantages of 1-20t/d palm kernel oil refining process line: 1. customized capacity.

manufacture crude palm oil refining machine,low cost price

next ,we take you through how palm oil refining machine works: palm oil refining refers to conversion from crude palm oil to refined oil removing hydrolysis and oxidation products, color and flavor. we adopts scientific designed small scale crude palm oil refining machine to process crude palm oil to obtain high quality refined palm oil.

palm kernel oil business

depending on your financial capacity, it can be run in a small, medium and large scale palm kernel oil mill plant. but the first problem coming to your mind may be where i can get palm kernel oil machinery (say palm kernel oil pressing machine, palm kernel oil processing unit, palm kernel oil refinery plant etc.) in good qualityp>

batch type palm oil refinery plant and continuous palm oil

in batch palm oil refinery process or palm kernel oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching deodorizing. for palm oil refinery plants capacity from 1 to 20 tons per day, batch type palm oil refinery process is recommended being low cost and easy to operate.

a brief introduction of palm oil plantation_manufacture palm

more and more palm oil plantations are now set up in southern asia and africa countries. it is a trend that palm oil mill will be mostly welcomed in near future. if you are interested in palm oil plantation and want to set up palm oil mill in advance, doing will help you with our advanced technology and best quality machines.

coconut oil refining line sld-topoilsolution.com

full continuous refining equipment. avocado oil, coconut oil, palm oil, etc., because of the different processing methods of raw materials, the hair oil usually has a higher acid value, and it is easy to use molecular distillation deacidification combined with intermittent degumming to carry out refining.

a brief introduction of palm oil plantation_manufacture palm

more and more palm oil plantations are now set up in southern asia and africa countries. it is a trend that palm oil mill will be mostly welcomed in near future. if you are interested in palm oil plantation and want to set up palm oil mill in advance, doing will help you with our advanced technology and best quality machines.

palm oil dry fractionation palm oil extraction machine

manufacturing palm oil dry fractionation,the doing palm oil dry fractionation process is designed to separate palm oil into two fractions, olein and stearin, without the addition of chemicals or solvents.same palm oil fractionation plant can be used for producing super olein and so on.

palm oil mill processing machines palm oil mill machine

8.palm oil mil process of clarification: machinepressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. the oil and the sludge taken out separated (by 90% pure oil) is taken out

1-20tpd palm kernel oil refining process line for sale

the refined palm kernel oil has high quality and is good for long time storage. the 1-20t/d palm kernel oil refining process line is suitable for rapeseed oil, cotton seed oil, soybean oil, peanut oil, etc. palm kernel oil refining process flow chart. advantages of 1-20t/d palm kernel oil refining process line: 1. customized capacity.

physical and chemical process in palm oil refining plant

the palm oil and palm kernel oil are steamed at a temperature of 240°c to 260°c to get away the odors and tastes, and then they are cooled into room temperature (about 55°c) for further use. this process have great impact on the quality of the final palm oil and palm kernel oil.

how to set up a palm kernel oil refinery plantw to refine

if you want to make the vegetable oil clean and pure and improves the overall quality of the oil, the palm kernel oil refining machine will be needed. in order to get high quality refined vegetable oil, we need to through four steps, they are: degumming, deacidification, decolorization/bleaching and deodorization.

palm kernel oil production line, palm kernel oil production plant

for example, either single machine or production line are both for sale. our palm kernel oil production line’s capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil production and refining process design, manufacture, installation, commissioning and after-sales service if it is needed.