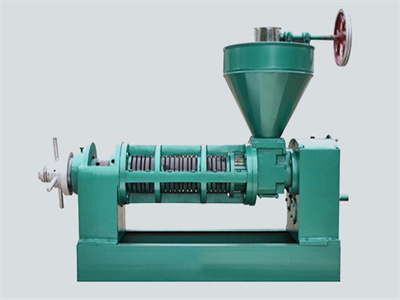

delhi oil mill refinery plant cooking oil refinery plant

- Applicable Industries:Machinery Repair Shops

- After-sales Service:Free spare parts, Field installation

- Dimension (L*W*H):1980*680*1460mm

- Production capacity:10 ton/day

- Voltage:380V/220V

- Weight:278 kg

- Power:2.2-18.5kw

- Advantage:Energy saving

- Raw material range:pumpkin seed,shea nut,black seed

- Transport Package: Wooden Case Packaging

- Color:Customer Required

edible oil refining oil extraction machine oil mill plant

we also provide professional customized edible oil refining and a variety of oilseed processing services. here you can find detailed information on our oil mill plant variations, and about our oil mill machinery, oil extraction machine, seed processing machinery, and oil filtering equipment

cooking oil refinery batch type vegetable oil refinery

in batch type vegetable oil refinery plant, processes are carried out by deodorizing, bleaching and neutralizing of certain quantity of oil. as the batch process is easy to operate and low in cost unfiltered matter and various impurities from seed like coloured, mucilage and gums are present in crude oil which is extracted from the expellers of.

oil extraction machine edible oil refining oil mill plant

established in 1986, we company deals principally in designing, manufacturing and exporting complete oil mill plants, solvent extraction plants and related oil processing equipment.we also provide professional customized edible oil refining and a variety of oilseed processing services.

cooking oil refining, cooking oil refinery, cooking oil

at tinytech udyog, we design and supply cooking oil refining plants which fulfill the above motive of impurity removal. our cooking oil refinery is designed to have series of steps such as degumming (to remove gums), neutralizing (to remove ffa), bleaching (to remove color), deodorizing (to remove odor and taste), and dewaxing (to remove waxes).

cooking oil refinery plant, batch oil refinery plant

in batch oil refinery process or cooking oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching deodorizing. crude oil obtained from expellers or solvent extraction plant contains foreign impurities such as mucilage, gums, coloured unfiltered proteinous matter from the seed.

oil mill machinery vegetable oil refining oil

we are a ce certified company specialized in manufacturing and exporting different types of oil mill machinery for varieties of oil seeds, we also offer customized complete set of oil plants like oil mill plant, oil extraction plant, oil refining plant etc. we company is your trustable manufacturer and supplier in china.

oil mill plant, oil milling, edible oil mill plant, oil

oil mill plant oil milling. with over 30 years of experience, we announce ourselves as leading manufacturers and exporters of oil mill plants and oil mill projects. due to constant rise and innovation in technology, we have come up with state-of-the-art oil mill machines for the efficient and effective extraction of oil.

great cooking oil refining technology oil mill plant

after getting of cooking oil of any oilseeds from the solvent extraction process, it sometimes needs to be refined in the oil refining plant to remove the ffa (free fatty acids), color and odor of the cooking oils.. our proprietary method of physically cooking oil refining uses a carefully balanced mixture of temperature, press, time, and natural clays in order to maximize finished oil.

edible oil refinery, vegetable oil refinery, cooking oil

edible oil refinery consists of soyabean oil refinery plant, coconut oil refinery plant and sunflower oil refinery plant. we also manufacture small scale mini oil refinery and batch type oil refinery plants from.

vegetable oil refinery, vegetable oil refinery plant

vegetable oil refinery plants very essentially convert the crude oils into high quality oil products that are fit for humans and also the oil modification processes that ensure that the physical properties of the fats and oils meet market requirements at minimal cost. this purpose is fulfilled in our vegetable oil refinery plant.

vegetable oil refinery plant vegetable oil refining

find here vegetable oil refinery plant, vegetable oil refining equipment manufacturers, suppliers exporters. get contact details address of companies manufacturing and supplying vegetable oil refinery plant, vegetable oil refining equipment across.

edible / vegetable oil refinery plant manufacturers

oil refinery plant refers to a series of refining processes that can remove phospholipids, ffa, pigment, off-flavor and other impurities in the oil.edible oil refinery or vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (f. f.a.) from the oil. to impart uniform colur by removal of coloring pigments and to get rid of unpleasant smell from.

professional oil refining plant for edible / vegetable oil

less bleaching earth necessary compared with physical refining; oil refining process. with 10 years&039; experience in manufacturing and exporting complete oil mill as well as a variety of oil mill machinery, kmec is an expert in edible oil refining. in the oil refining plant, there are several steps to follow.

edible oil refinery, vegetable oil refinery, cooking oil

soyabean oil refinery plant. the extruded crude soya oil can be sent to our soya oil refinery for making purest rbd soyabean oil. this is further widely consumed for cooking applications and penetrates into the supermarkets to thousands of consumers.

manufacturering cooking oil making machine, edible oil

providing edible oil refinery plant. edible oil refinery plant is to refine the crude oil obtained from pressing and solvent extraction plants. only after refining, the crude oil becomes edible oil. based on the requirements of the clients, the company can provide three types of edible oil refinery batch, semi-continuous and fully continuous.

oil mill machinery, tinytech mini oil

'tinytech plants&039;, established in the year 1983, is the pioneer in oil mill machinery, palm oil mill machinery, refinery plants not only but we have large customer base all over the world in 119 countries. 'tinytech plants&039; began by manufacturing mini oil mill to produce oil from any kind of oil seeds.

vegetable oil refinery plant manufacturers

we are leading manufacturer and exporter of vegetable oil refinery plant from we are leading manufacturer and exporter of vegetable oil refinery plant such as (batch type refinery, continuos bleaching, physical refining / deodorization, dewaxing / winterization, dry fractionation, solvent extraction plant, oil extraction machinery )

oil mill plant machinery supplier,oil expellers, oil mill

the technical teams are ready to help you design and install oil mill plant project based on your oilseed type, yield budget. numbers of oil mill plants for manufacturing soybean oil, peanut oil, coconut oil, sesame oil,cottonseed oil, rapeseed oil, sunflower oil, corn germ oil, palm oil and palm kernel oil, etc. have been exported installed to various countries like,.

professional oil refining plant for edible / vegetable oil

edible/vegetable oil refining. edible/vegetable oil refining is a step by step process. refining oil removes phospholipids, pigments, off-flavors, free fatty acids and other impurities. the entire oil refining plant process comprises degumming/neutralization, bleaching, deoderization, and winterization. chemical refining is performed in order.

chemical batch type vegetable oil refinery plant

mustard oil mill plant mustard oil extraction plant ... batch type vegetable oil refinery plant batch type vegetable oil refinery plant, procedures are carried out in series of neutralizing, bleaching deodorizing for a measured quantity of oils. batch process is recommended for plants capacity as it is low cost and easy to operate.