crude oil refinery technology oil refining plants in ndola

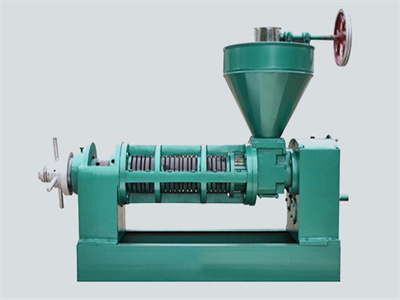

- Applicable Industries:Food & Beverage Factory, Food Shop

- After-sales Service:Technology Supporting

- Dimension (L*W*H):182*57*132cm

- Production capacity:150-200 kg/h

- Voltage:220V/380V

- Weight:580kg

- Power:Y315m-6-45kw

- Advantage:Best price

- Raw material range:black seed,shea nut,pine nut,coconut meat

- Transport Package: Export Fumigation-Free Wooden Box

- Method to press:Screw Squeezed Press

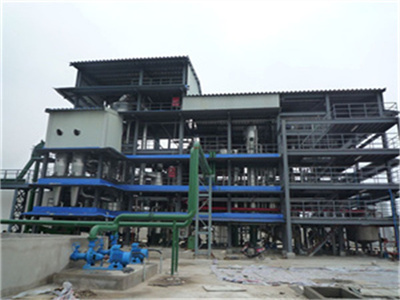

batch type crude cooking oil refining production machine

batch type crude cooking oil refining production machine small scale edible oil refining machine , find complete details about batch type crude cooking oil refining production machine small scale edible oil refining machine,palm oil refinery,refined sunflower oil from,palm oil refinery tanks from oil pressers supplier or manufacturer-henan doing environmental protection

lost in oil rally: $2 trillion-a-year refining industry pain

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin.

crude oil-to-chemicals: future of refinery futurebridge

crude oil-to-chemicals (cotc) technology allows the direct conversion of crude oil to high-value chemical products instead of traditional transportation fuels. it enables the production of chemicals exceeding 70% to 80% of the barrel producing chemical feedstock as opposed to ~10% in a non-integrated refinery complex.

crude oil refining machine/refinery for sale /fish oil

crude oil refining machine/refinery for sale /fish oil refining plant,they are suitable for pressing rapeseed, cottonseed, soybean, peanut, black seed, tung seed, sunflower seed and palm kernel and other vegetable oilseeds.

crude oil: lost in oil’s rally: $2 trillion-a-year refining

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin.

oil refinery types petroleum refining explained tank farm

an oil refinery or petroleum refinery is an industrial process plant purposely built for transformation and refining of crude oil into more useful products such as gasoline, diesel fuel, heating oil, kerosene, liquefied petroleum gas, jet fuel, asphalt base, heating oil, and fuel oils.

lost in oil rally: $2 trillion-a-year refining industry pain

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin.

crude oil: lost in oil’s rally: $2 trillion-a-year refining

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin.

oil refinery types petroleum refining explained tank farm

an oil refinery or petroleum refinery is an industrial process plant purposely built for transformation and refining of crude oil into more useful products such as gasoline, diesel fuel, heating oil, kerosene, liquefied petroleum gas, jet fuel, asphalt base, heating oil, and fuel oils.

crude oil refining machine/refinery for sale /fish oil

crude oil refining machine/refinery for sale /fish oil refining plant,they are suitable for pressing rapeseed, cottonseed, soybean, peanut, black seed, tung seed, sunflower seed and palm kernel and other vegetable oilseeds.

crude oil refining in africa the way forward

most refineries in africa tend to be medium to large-scale refineries, perhaps because of the state of technology at the time they were built. this article is about presenting a cost- effective and timely option, as represented by the modular refining format. review of crude oil refining in africa: there are a total of…

petroleum refining refinery plant and facilities britannica

conversion refineries. the most versatile refinery configuration is known as the conversion refinery. a conversion refinery incorporates all the basic building blocks found in both the topping and hydroskimming refineries, but it also features gas oil conversion plants such as catalytic cracking and hydrocracking units, olefin conversion plants such as alkylation or polymerization units, and

crude oil refining in africa the way forward

most refineries in africa tend to be medium to large-scale refineries, perhaps because of the state of technology at the time they were built. this article is about presenting a cost- effective and timely option, as represented by the modular refining format. review of crude oil refining in africa: there are a total of…

crude oil: lost in oil’s rally: $2 trillion-a-year refining

a refinery’s economics are ultimately simple: it thrives on the price difference between crude oil and fuels like gasoline, earning a profit that’s known in the industry as a cracking margin.

crude oil refining machine/refinery for sale /fish oil

crude oil refining machine/refinery for sale /fish oil refining plant,they are suitable for pressing rapeseed, cottonseed, soybean, peanut, black seed, tung seed, sunflower seed and palm kernel and other vegetable oilseeds.

total inks deal to shed refinery, downstream assets oil

total se has agreed to sell its downstream business—including subsidiary total lindsey oil refinery ltd.’s 109,000-b/d refinery in north killinghome, immingham, lincolnshire, and associated

some of america’s edible oil refinery machine may be on brink of shutting

“it’s complicated to keep the refinery in balance,” said stephen wolfe, head of crude oil at consultant energy aspects ltd. “the rule of thumb for me was always 65% of the cdu. below that

oil_refinery

edible oil refinery machine are large scale plants, processing from about a hundred thousand to several hundred thousand barrels of crude oil per day. because of the high capacity, many of the units are operated continuously (as opposed to processing in batches) at steady state or approximately steady state for long periods of time (months to years).

southern approves plans for 50,000-b/d refinery oil

southern's state-owned nilepet corp. is to form a joint venture with the winner of the bid. the government plans another refinery for the dar blend oil fields in the upper nile region, lsaid.

oil_refinery

edible oil refinery machine are large scale plants, processing from about a hundred thousand to several hundred thousand barrels of crude oil per day. because of the high capacity, many of the units are operated continuously (as opposed to processing in batches) at steady state or approximately steady state for long periods of time (months to years).

crude palm oil refining machine palm oil fractionation plant

doing provide high technology crude palm oil refinery plant . crude palm oil refinery plant is used to refine palm oil to edible oil.doing group offer mini, small scale palm oil refinery palnt,offer turn-key solutions for crude palm oil refinery plant,adopts physical and chemical refining methods to refine palm . get price

the process of crude oil refining eme 801: energy markets

presenter: for crude oil to be used effectively by modern industry, it has to be separated into its component parts and have impurities like sulfur removed. the most common method of refining crude is the process of fractional distillation. this involves heating crude oil to about 350 degrees celsius, to turn it into a mixture of gases.

refining crude oil the refining process u.s. energy

petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks for making chemicals. refining breaks crude oil down into its various components, which are then selectively reconfigured into new products.

new technology waste palm oil refinery plant grain and oil

fractionation technology palm oil refining plant offers 10-20kg/t oil. oil content in waste is a new oil processing technology. using palm oil . send inquiry; china new technology crude palm oil refining equipment . china new technology crude palm oil refining equipment, oil plant, find details about china oil press equipment, oil refinery from new