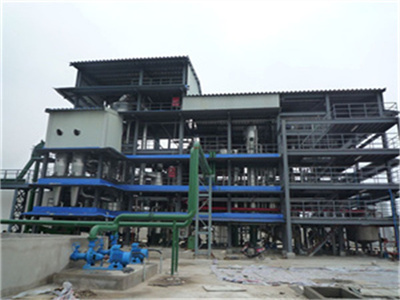

lusaka complete edible oil refining plant cooking oil refinery plant

- Applicable Industries:Food Shop

- After-sales Service:Online support, Spare parts

- Dimension (L*W*H):3740*1920*3843mm

- Production capacity:5-30t/d

- Voltage:380V/220V

- Weight:1042kg

- Power:5kw

- Advantage:Low Residual

- Raw material range:linseed,palm fruit,corn germ,pepper seed,shea nut

- Transport Package: Fumigated Wooden Box or as Customer′s Request

- Appearance:Vertical

complete edible oil plant,cooking oil refinery plant

palm oil refinery plant is different as normal vegetable oil , including palm oil refining and palm oil fractionation. tpd5 flaxseed oil refining and dewaxing line in china dayang installed tpd5 flaxseed oil refining and dewaxing line which is used for making flaxseed oil capsule.

edible oil refinery, edible oil refinery plant, edible oil

edible oil refinery and edible oil refining have been the areas of excellence for tinytech udyog. we are based and since 1990 we have been the basic designers, manufacturers and exporters of complete edible oil refinery plants to convert the crude oils into pure rbd oils.

edible oil refinery plant manufacturers and exporters

process description of edible oil refinery plant. as per the today market research it is being concluded that the market demands the refined edible oil with characteristics such as bland flavour and odour, clear appearance, light colour, long shelf life, suitable for frying since the crude oil obtained does contains many harmful factors like free fatty acids (ffa), sediments, gums, odoriferous.

soya bean oil refinery plant manufacturer

edible oil refinery machine manufacturer supplies vegetable oil refinery plant for refining crude palm oil, soybean oil, sunflower oil, etc, with mature oil refining technology and factory price.soybean oil plant. 2tph palm kernel cracker and separator machine successfully installede.

undertake edible oil refinery plant from 1tpd to 500tpd

edible oil refinery with a growing world population, the demand for edible oil is also increasing year after year. since most crude vegetable oils obtained either from expellers or solvent extraction plant contains impurities and need to be (at partially) refined for edible or technical applications, increased production volumes have resulted in a serious expansion of the edible oil refinery.

widely used hot sale edible oil refinery plant for edible oil

new condition edible oil refining plant / crude oil refinery plant. the edible oil refining plant is widely used for various oil seeds, such as soybean, sesame, sunflower seed, peanut, cocoa bean, rape seed, etc. 2.features of new condition edible oil refining plant / crude oil refinery plant / palm kernel oil processing machine

vegetable oil refinery, vegetable oil refinery plant

the refining capacity of the vegetable oil refinery is generally expressed as tons per day (tpd) in 24 hours. thus, an oil refinery must operate continuously for 24 hours a day to get the output results and to allow the adequate time for process completions.

edible oil refinery, vegetable oil refinery, cooking oil

edible oil refinery consists of soyabean oil refinery plant, coconut oil refinery plant and sunflower oil refinery plant. we also manufacture small scale mini oil refinery and batch type oil refinery plants from.

edible oil refinery, vegetable oil refinery, cooking oil

what we serve is equally important to what we offer. with over 25 years of existence in our field, we have gained incredible expertise in providing services in terms of process development, technical evaluation studies, design of plants, oil refinery equipment, improvement and expansion of existing facilities, studies from the point of view of pollution prevention, energy conservation the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.

edible oil refinery, vegetable oil refinery, cooking oil

edible oil refinery plants and edible oil refining are of vital consideration when it comes to edible oil technology. we manufacture and export cost effective mini oil refinery plants along with customized solutions for cooking oil refinery.

vegetable oil refinery plant manufacturers

we are leading manufacturer and exporter of vegetable oil refinery plant from we are leading manufacturer and exporter of vegetable oil refinery plant such as (batch type refinery, continuos bleaching, physical refining / deodorization, dewaxing / winterization, dry fractionation, solvent extraction plant, oil extraction machinery )

how is edible oil refinedat is edible oil refining

refined edible oil is obtained through further processed by series of machines in edible oil refinery plant, and then after refining, the edible oil you got from edible oil pressing plant or edible oil solvent extraction plant will become standard refined oil. usually edible oil refining process includes degumming, deacidifaction.

cooking oil refinery batch type vegetable oil refinery

we present one of the most developed cooking oil refinery plant for processing of edible oil. there are primarily involved two types of processing- batch type and continuous. through these processes, the oil is separated from impurities and other materials that can make it unfit for edible purpose.

manufacturering cooking oil making machine, edible oil

providing edible oil refinery plant. edible oil refinery plant is to refine the crude oil obtained from pressing and solvent extraction plants. only after refining, the crude oil becomes edible oil. based on the requirements of the clients, the company can provide three types of edible oil refinery batch, semi-continuous and fully continuous.

peanut oil refining plant technology and install/edible

peanut oil refinery plant is a set of machines, with which we can get standard edible peanut oil. in the production process of peanut oil refinery plant, we utilize the physical methods and chemical processes according to the different usage and requirements to get rid of the harmful impurities and needless substance in the crude peanut oil.

how to set up a cooking oil refinery plant with small

of course, the cost of full-continuous cooking oil refinery plant is the most. batch type cooking oil refinery plant 3d picture. so, if you want to set up a cooking oil refinery plant with small budget, the batch type cooking oil refinery plant is your best choice, which can be customized into 1-20 tons per day.

edible oil refinery plant, edible oil refinery, edible oil

our edible oil refinery plants and oil mill machinery plants are unique in its class equipped with latest technological features giving excellent performance satisfaction. get in touch with us if you are looking for batch or continuous vegetable oil refining line. quality: the company beleives that the most important aspect in any field is quality.

how to setup 1~5tpd mini oil refinery plant

oil refining process, the most important section of a complete cooking oil manufacturing plant, can't be ignored. mini oil refinery plant is the no.1 choice for small or medium scale oil mill plant to improve the oil quality and reduce the oil production cost.

vegetable oil refining plant manufacturer edible oil

mectech is a leading vegetable oil refining plant manufacturerin.solvent extraction and distillation process produce crude oil, which contains inherent harmful constituents like free fatty acids (ffa’s), gums, sediments, odoriferous and coloring materials, phosphatides, hydrocarbons, traces of pesticides and heavy metal, that need to be refined for human consumption.

how much does a medium cooking oil refinery plant cost

as the demand for edible oil quantity and quality keep growing, more and more businessman are interested in setting up a medium cooking oil refinery plant. in fact,many factors need to be thinked.the first factor is the cost of a medium cooking oil refinery plant.