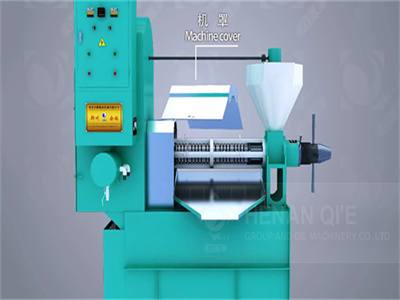

uganda high oil yield groundnut oil extraction process machine

- Applicable Industries:Manufacturing Plant

- After-sales Service:Service Machinery Overseas

- Dimension (L*W*H):1030*900*870mm

- Production capacity:1-10 ton per day

- Voltage:110V/220V/380V

- Weight:830kg

- Power:55+11+4kw

- Advantage:Top brand

- Raw material range:coconut meat,soybean,gape seed,sunflower seed,pepper seed

- Transport Package: Wooden Box

- Origin:Zhengzhou, China

groundnut oil processing mill setup cost in africa

small size groundnut oil processing mill. cleaning: this process adopts cleaning sieve or other cleaning machine to remove the stones, metals, and other impurities from the groundnuts. the less of the impurities in the groundnuts after screening, the better of the groundnut oil extraction process. the impurity rate is less than 0.1%.

how to start a groundnut oil plant with simple machines

groundnut oil press machine: the oil press is the core of the groundnut pressing process. generally speaking, there are two types of groundnut oil pressing machine, a single-screw groundnut oil press machine, and an integrated groundnut oil press machine. the single-screw oil press has a simple structure and is easy to operate.

best groundnut oil mill machinery for small production line

small scale groundnut oil milling process. small groundnut oil mill machinery connects a series small oil processing equipment together to achieve continuous oil extraction. because it is fully mechanical driven, it can accomplish easier operation and high rate of oil yield. by the way, it can deal with almost all kinds of oil seeds.

big capacity groundnut cooking oil making processing

in order to improve oil y ie ld rate and get high quality peanut oil, the groundnut oil machine price should consist following processes: pretreatment, prepressing, solvent extraction and refining. these large oil presses are generally divided into two kinds: oil press for hot pressing, and low temperature oil press for cold pressing.

groundnut oil making process (peanut), business plan

groundnuts solvent extraction process. generally, the groundnut or peanut solvent extraction is a procedure which involves extracting oil from oil-bearing materials by treating it with a low boiler solvent as opposed to extracting the oils by mechanical pressing methods that are expellers, hydraulic presses, etc. the solvent extraction process recovers almost all the oils and leaves behind 0.5.

peanut/groundnut oil extraction process for sale _factory

peanut/groundnut oil extraction process machinery adopts the most advanced peanut/groundnut oil extraction technology to ensure high efficiency, economical and reliable crude peanut/groundnut oil extraction process. cooperated with vacuum evaporation oil extraction design, solvent condensation and tail gas recovery system, the peanut oil extraction process machinery can obtain crude peanut.

peanut oil press machine/peanut oil production line

high quality peanut oil press machine adopt the latest pre-press oil extraction process technology, at present, this technology is the most advanced in the world, and it makes up for lack of traditional oil press and improve the oil yield, ensure the quality of peanut oil ,improve the quality of peanut meal, to provide a guarantee as high protein forage material.

peanut oil production line, automatic production line

the peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. peanuts are high-oil-containing oilseeds. currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical production”.

groundnut varieties with higher oil content empowering

the yadakwari women’s community service centre is now using these improved varieties to produce more groundnut oil (up to 350 liters per week) in addition to kuli-kuli (a popular local groundnut-based snack; see box). the demand for locally pressed groundnut oil and kuli-kuli is so high that they are being immediately sold in the local markets.

best edible oil extraction machine manufacturer supplier

about we company is a large-scale oil mill machinery manufacturing enterprice integrating r d,design, manufacture and installation.we are specialized in peanut oil extraction machine, soybean oil extraction, corn germ oil extraction machine, cottonseed oil extraction machine, rapeseed oil extraction machine, sunflower oil extraction.

groundnut oil production how to start business plan guide

groundnut oil production process technology basically, you can divide the edible oil technology into two groups. these are mechanical pressing and solvent extraction. for oilseeds with high oil content such as groundnut, you will need to apply first mechanical pressing. here, you can extract over 85% of the oil.

(pdf) an overview of groundnut oil extraction technologies

groundnut oil extraction involves removing oil content of the groundnut seed. study conducted in northern revealed that 75% of the rural women engaged in groundnut oil extraction used the.

design and fabrication of a groundnut oil expelling machine

of an automated groundnut oil extractor was aimed to produce pure groundnut oil which would be better than the common vegetable oil (refined,blenched and deodorized palm oil)due to its natural process of extraction this machine this machine designed to the power a by 075kw electric motor with 1400 rpm and 50hz single

groundnut oil manufacturing process-dayang offers

groundnut oil manufacturing process: 1. groundnut oil press process: a. groundnut →magnetic roller→destoner→screening→grading( small group with higher quality and big group with normal quality) -magnetic roller is to remove metallic impurities. -destoner is to remove small stones. -screening is to remove other impurities.

groundnut oil extraction machine 2024 best price

factory supply 100-500kg/h groundnut oil processing machine; this copra small cold press oil machine is made and distributed from china. it is regarded as one of the highest yield machines you can find. it guarantees you 92% of oil yield and does not affect the quality of the oil in any way. auto groundnut oil processing machine by zhengzhou qie.

(pdf) groundnut production constraints, farming systems

groundnut agronomic attributes preferred by farmers were as follows: high yield (reported by 78.4% of respondents), disease resistance (71.2%), early maturity (66%), drought tolerance (63.0%), the oil press machine adopts physical pressing by using spiral extrusion to generate high temperature. it only takes a few minutes from the feeding to the finished product at one time.

groundnut oil extraction machine for sale,groundnut oil

groundnut oil extraction machine for sale,groundnut oil extraction process,this groundnut oil production machine uses an electric pipe to heat the press case, which helps the press case meet.

small scale groundnut oil processing machine set for sale

this small scale groundnut oil processing machine set is fully adopted mechanical driven, it connects each oil production machinery together to extract oil with higher oil yield (including, cooker, conveyor and multifunction oil press with filter). here is the details and features of the small scale oil production machine:

high yield sautomatic soybean oil press machine

1.high yield sautomatic soybean oil press machine have the high quality and high performance.shandong leader machinery co.,ltd. use the stainless steel instead of the carbon steel for high yield sautomatic soybean oil press machine. 2. shandong leader machinery co.,ltd. buy directly from the manufacturer for guaranteeing the quality.

groundnut small cold press oil machine palm kernel oil extraction machine

factory supply 100-500kg/h groundnut oil processing machine; this copra small cold press oil machine is made and distributed from china. it is regarded as one of the highest yield machines you can find. it guarantees you 92% of oil yield and does not affect the quality of the oil in any way. auto groundnut oil processing machine by zhengzhou qie