kampala complete line mt per hr palm kernel oil processing mill

- Applicable Industries:Building Material Shops

- After-sales Service:Service Machinery Overseas

- Dimension (L*W*H):1010*850*870mm

- Production capacity:1t/d

- Voltage:220V/380V

- Weight:5500kg

- Power:75+11+5.5kw

- Advantage:Low Residual

- Raw material range:pumpkin seed,flaxseed,avocado

- Transport Package: Export Fumigation-Free Wooden Box

- Specification:CE, ISO

complete farm processing palm kernel oil extraction

cost on setup palm oil processing mill. a complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around. note: the exact cost of starting a palm oil milling . get price

set up a palm kernel oil processing unit for ... oil mill

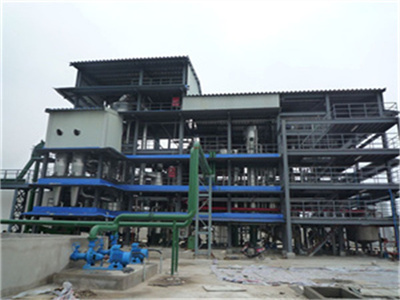

the oil then requires clarification in a filter press or by sedimentation. extraction is a well-established industry, with large numbers of international manufacturers able to offer equipment that can process from 10 kg to several tonnes per hour. the picture on the right shows the palm kernel oil processing unit. palm kernel and palm kernel oil

palm oil mill screw oil press machine

palm oil is extracted from fresh fruit bunches (ffb) by a mechanical process, where a mill commonly handles 2.5 to 150 mt per hour of ffb. the quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the ffbs and the process adopted. a palm oil mill produces crude palm oil and kernels as primary.

cost on setup palm oil processing mill

a complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around. note: the exact cost of starting a palm oil milling business depends on the capacity requirments, process design and equipment configuration.

commissioning of palm oil mill company announcement ft.com

palm oil mill (&034;pom&034;) the pom at palm bay estate has now been commissioned and is producing crude palm oil (&034;cpo&034;) and palm kernels, which are being stored on site awaiting shipment to customers. as announced on 6 march 2024, the pom is being constructed in a modular fashion, with two lines of 30 metric tonnes per hour (&034;mt/hr&034;).

palm oil mill process_manufacture palm oil extraction

palm oil mill process includes 6 parts: palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery. 1. palm oil mill process of fruits receiving: collecting the ripe fresh cluster from the orchard and convey by trucks, then pour the fluster into the discharge door after weighed by ground.

manufacture palm oil mill process,low cost price for sale

palm oil mill process is quite different from other oil seeds processing. palm oil mill process includes 6 parts: palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery.our palm oil mill process is low cost and energe-saving.

palm kernel oil production line, palm kernel oil extraction machine

for example, either single machine or production line are both for sale. our palm kernel oil production line’s capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil production and refining process design, manufacture, installation, commissioning and after-sales service if it is needed.

ffb (fresh fruit bunch) of oil palm into cpo (crude palm

palm oil is extracted from fresh fruit bunches (ffb) by a mechanical process, where a mill commonly handles 2.5 to 150 mt per hour of ffb. the quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the ffbs and the process adopted. a palm oil mill produces crude palm oil and kernels as primary.

small-scale build of palm oil processing plant

palm oil 101 production processing milling refining fractionation blending products propertiesedible oil palm mill . oil extraction at the mill ffbs enter the mill for processing ... hydrogenated palm kernel oil hydrogenated palm kernel olien

process flowchart for palm kernel oil production with good price

palm kernel processing flow chart shows how the seed is processed to make oil from palm kernel seed. leading manufacturer of palm kernel oil press machine.

factory price small palm kernel oil extraction machine

the kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying. the nut processing and oil extraction is undertaken in the dry season when the press to obtain raw materials has subsided. the traditional palm oil processing starts with the shelling of the palm nuts.

small capacity palm oil extraction machine for palm fruit ( kernel)

palm oil production line includes three main sections, palm oil pressing plant, palm oil refinery plant and palm oil fractionation plant. as the manufacturer of the palm oil production line, huatai oil machinery can offer the whole line or part of the palm oil production line for different capacities with turnkey services.

palm oil extraction process, methods, steps agri farming

palm oil types: red palm oil: red palm oil has been cold-pressed from the fruit of the oil palm and bottled for use as cooking oil, in addition to other uses such as being blended into mayonnaise and vegetable oil. white palm oil: white palm oil is the product of processing and refining. when refined, the palm oil loses its red color.

palm kernel oil extraction production process and profit

the above profit is for processing 1tone of palm kernel. now, if you process 2 tone per day, you get n20,000 x 2 = n40,000 per day as profit, which by extension implies a monthly profit of n1,120,000 (24days). profit increases as production increases.

palm and palm kernel oil production and processing

introduction. the oil palm industry has proven to be one of the most important industries and. as of 2009, a total of 4.69 million hectares were planted with oil palm, with 2.4 million hectares in peninsular, 1.36 million hectares in sabah, and 0.71 million hectares in sarawak ().due to the scarcity of new land for plantation development in peninsular.

modern palm oil processing method

generally, processing units handling up to 2 tones of fresh fruit bunches (ffb) per hour are considered to be small-scale. installations that process between 2 and 8 tones ffb per hour are termed medium-scale, while large-scale redres to mill that process more that 10 tones per hour. palm oil processing flow chart:

methods of palm oil processing in ogun state,: a

the oil palm is one of the important economic crops in the tropics (anyawu et al., 1982). it is the most important source of oil and produces more oil per hectare than any of the oil producing crops. the primary products of the oil palm are palm oil (from the mesocarp) and palm kernel oil obtained from the kernels (seeds). palm oil contains

financial model for palm oil mill and kernel nut mill

2. operating a medium-scale oil mill of 5tons/hour starting in year 2 but fully operational by year 3 with ffb from our current 1,500-hectare plantation while growing our plantation (remember we will probably start at 70% capacity in 1 st year of operation, then increase to 80% then 90%, also note production operation shifts in projected output table below).

what machines are used in palm kernel oil extraction process2>

we company is a professional manufacturer of palm kernel oil processing machine, we can supply different palm kernel oil processing equipment to meet different customer's needs. during palm kernel oil extraction process, not all the palm kernel oil machines are necessary, some equipments can be replaced by manual labour.