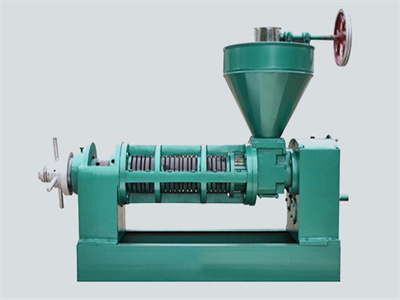

palm oil refining plant 20ton day semi continuous deodorization

- Applicable Industries:Manufacturing Plant

- After-sales Service:Free spare parts, Field installation

- Dimension (L*W*H):1500*1200*1700mm

- Production capacity:150t/d

- Voltage:420V

- Weight:610 kg

- Power:0.85kw

- Advantage:High Oil Yield

- Raw material range:peanut,palm,copra

- Transport Package: Export Wooden Crates

- Automatic:Automatic Grade

turnkey project of palm oil refinery plant physical refining machine

batch refinery plant: 1tpd,2tpd, 3tpd, 5tpd,10tpd,15tpd, 20tpd, 30tpd. (suitable for mini and small palm oil refining factory); semi-continuous refinery plant: 15tpd,20tpd.30tpd (suitable for middle-sized palm oil processing plant)

palm oil refinery plant, manufacturing vegetable oil products

palm oil deodorization is the final process of edible palm oil refinery plant. it is a result of heating-crushing and heating extraction development. odiferous material and other minor undesired particles are removed from the crude palm oil or palm kernel oil in the deodorization process of palm oil.

set up a palm kernel oil refinery plant with low cost, palm

according to the processing capacity and automation degree, palm kernel oil refinery plant can be divided into batch type palm kernel oil refinery plant (less than 20 tons per day), semi-continuous palm kernel oil refinery plant (20-50 tons per day), continuous palm kernel oil refinery plant (more than 50 tons per day).

deodorization oil chemists&039; society

today, deodorizers with a capacity of more than 1500 tonnes per day have become more or less standard, especially for the deodorization of commodity oils (e.g. palm oil, soybean oil, etc.). variable processing costs are determined by the energy consumption for the heating of the oil, generation of the vacuum and production of stripping steam.

manufacture 1-1000tpd palm oil refinery plant,low cost price

as for the semi-continuous palm oil refinery plant, we have the below capacity: 10t/day, 20t/day, 30t/day, and 50t/day. semi-continuous palm oil refinery plant is popular in middle palm oil mill plant

manufacture 50tpd continuous palm oil refinery plant,low cost

manufacturing 50tpd continuous palm oil refinery plant,this 50tpd continuous palm oil refinery plant is designed for continuous operation. continuous palm oil refinery plant is recommended against the batch refining for higher capacity plants above 30 tons per day.

what is continuous palm oil extraction plant2>

batch and semi-continuous palm oil extraction plant the nozzle may be moved by hand or mechanically (using a motor). the mechanical technique is quicker but it costs more money to utilize.diverse designs use different methods; a screw press uses a screw thread, and a hydraulic press uses a lift system to move the nozzle about.

physical and chemical process in palm oil refining plant

according to the degree of automation, the refinery process can also be divided into batch refinery plant, semi-continuous refinery plant and continuous refinery plant. batch type is the ideal choice for mini and small sized production (1-20tpd), while the latter two are normally designed for middle-large size production line (10-50tpd).

physical and chemical process in palm oil refining plant

according to the degree of automation, the refinery process can also be divided into batch refinery plant, semi-continuous refinery plant and continuous refinery plant. batch type is the ideal choice for mini and small sized production (1-20tpd), while the latter two are normally designed for middle-large size production line (10-50tpd).

20ton/day palm kernel oil processing machine / plant

it is a 20ton/day palm kernel oil mill plant including refining and fractionation machinery, and constructed 4pc 300metric tons oil storage tanks,also set up filling line and lab instrument.. the refining plant is based on semi-continuous refining process. degumming and deacidification process is batch and deodorization process is continuous.

set up a palm kernel oil refinery plant with low cost, palm

according to the processing capacity and automation degree, palm kernel oil refinery plant can be divided into batch type palm kernel oil refinery plant (less than 20 tons per day), semi-continuous palm kernel oil refinery plant (20-50 tons per day), continuous palm kernel oil refinery plant (more than 50 tons per day).

5tpd palm oil refinery plant project_projects

the 5tpd palm oil refinery plant project is designed according to our customer's requirement. he want to get higher quality refined palm oil, so the deodorization part uses automatic deodorizing tower. but the cost is higher, too. in a word, 5tpd oil refinery plant can be designed into batch type or semi-continuous type.

batch type palm oil refinery plant and continuous palm oil

our company is specialized in palm oil refinery plant.we can provide the palm oil refinery plant from 1 ton to 1000 tons. in general, batch type palm oil refinery plant is with capacity 1-20tpd; the semi-automatic palm oil refinery plant is suggested with capacity from 20-50tpd; and continuous palm oil refinery plant is used for capacity above 50tpd.

what is continuous palm oil extraction plant2>

batch and semi-continuous palm oil extraction plant the nozzle may be moved by hand or mechanically (using a motor). the mechanical technique is quicker but it costs more money to utilize.diverse designs use different methods; a screw press uses a screw thread, and a hydraulic press uses a lift system to move the nozzle about.

coconut oil refining line sld-topoilsolution.com

full continuous refining equipment. avocado oil, coconut oil, palm oil, etc., because of the different processing methods of raw materials, the hair oil usually has a higher acid value, and it is easy to use molecular distillation deacidification combined with intermittent degumming to carry out refining.

turnkey edible oil refinery line all capacities

semi-continuous oil refinery 10-50tpd. semi-continuous oil refinery process design is more efficient and needs less investment. it’s suitable for middle scale oil refinery plant from 10tpd to 50tpd.... read more

set up a palm kernel oil refinery plant with low cost, palm

according to the processing capacity and automation degree, palm kernel oil refinery plant can be divided into batch type palm kernel oil refinery plant (less than 20 tons per day), semi-continuous palm kernel oil refinery plant (20-50 tons per day), continuous palm kernel oil refinery plant (more than 50 tons per day).

semi-continuous oil refinery 10-50tpd build oil mill plant

the semi-continuous oil refinery capacity can be designed according to customer requirement. it’s suitable for the middle type oil refinery plant from 10tpd to 50tpd. so it is also called middle scale oil refinery unit. raw material the semi-continuous oil refinery plant has widely scope of raw materials. it can deal with different kinds of oil.

20tpd palm kernel oil refinery and fractionation plant

20tpd semi-continuous palm kernel oil refinery and fractionation plant was sucessfully setup in 2019 by abc machinery.all the palm kernel oil refining machine was manufactured, installed, commissioned by us to ensure high oil yeild.

semi-continuous edible oil refinery

5. whole of the deodorization is going under the vacuum. the vacuum can avoid the oxidation of oil and improve the quality of oil. 6. the stripping and distillation are used to keep the taste and stabilize of the final oil. main equipments of semi-continuous edible oil refinery plant: refining pot: it also be called degumming and

edible oil refining palm oil refining plant exporter

exporter of edible oil refining palm oil refining plant, fractional distillation plant, vegetable oil refining plant and alkali refining plant offered by muez hest private limited, mumbai, maharashtra.

palm oil refinery plant and palm oil refinery method_palm oil

semi-continuous refinery (10-50tpd)15tpd,20tpd.30tpd (suitable for middle-sized palm oil refinery factory) large scale palm oil refinery plant for industrial business plan. continuous palm oil refinery (50-600tpd) 30tpd ,50tpd,100tpd,200tpd,400tpd (suitable for industrial scale palm oil mill plant) small scale palm oil refineyr plant

palm oil refinery at best price

automatic grade: automatic, semi-automatic. design: customized, standard. we supply palm oil refinery plant. application: turnkey refining plants for vegetable oils such as soya oil, sunflower oil, palm oil , corn oil, and rice bran

how to start a coconut oil refining factory in the2>

as his business growing, now, he want to reconstruct the oil extraction production from 20tpd to 50tpd, transform the deodorization section of the refinery from batch process to semi-continuous process, and expand the deodorization production to 20 ton/day.

semi-continuous edible oil refinery

5. whole of the deodorization is going under the vacuum. the vacuum can avoid the oxidation of oil and improve the quality of oil. 6. the stripping and distillation are used to keep the taste and stabilize of the final oil. main equipments of semi-continuous edible oil refinery plant: refining pot: it also be called degumming and

30tpd palm oil refinery plant project_projects palm

this is a palm oil refinery plant project of henan doing company in 2013. it contains not only palm oil refining line, but also soap production line. with 30 tons per day input capacity, it is semi-continuous type palm oil refinery plant. actually, semi-continous type has better deacidification and deodorization effect.

edible oil refining palm oil refining plant exporter

exporter of edible oil refining palm oil refining plant, fractional distillation plant, vegetable oil refining plant and alkali refining plant offered by muez hest private limited, mumbai, maharashtra.

batch type edible oil refinery machine for sale batch oil

features of doing batch type edible oil refinery machine: 1. easy to operate, less workers, low cost, small footprint. 2. widely used: batch type edible oil refinery machine can be used to refine various edible oil. 3. customized capacity: doing batch type edible oil refinery machine capacity has 1/2/3/5/10/20 ton per day you can choose. 4.

palm oil refinery at best price

automatic grade: automatic, semi-automatic. design: customized, standard. we supply palm oil refinery plant. application: turnkey refining plants for vegetable oils such as soya oil, sunflower oil, palm oil , corn oil, and rice bran

edible oil refining edible oil refinery plants manufacturer

highly modern process plants with automation ranging between 100 to 700 mt per day feed capacity. we are the basic designers, manufacturers, and exporters of complete edible oil refinery plants to refine the crude oil and make it pure edible.

5 ton edable oil refinary plant oil pressing machine supplier

oil refining plant is 20ton/day semi-continuous deodorization. oct 14, 2015· the oil refining plant is 20ton/day semi-continuous deodorization. customer oil extraction plant is 50ton/day coconut oil pressing line, refining equipment is 20ton/day semi-continuous deodorization. get price

palm oil refinery plant and palm oil refinery method_palm oil

semi-continuous refinery (10-50tpd)15tpd,20tpd.30tpd (suitable for middle-sized palm oil refinery factory) large scale palm oil refinery plant for industrial business plan. continuous palm oil refinery (50-600tpd) 30tpd ,50tpd,100tpd,200tpd,400tpd (suitable for industrial scale palm oil mill plant) small scale palm oil refineyr plant