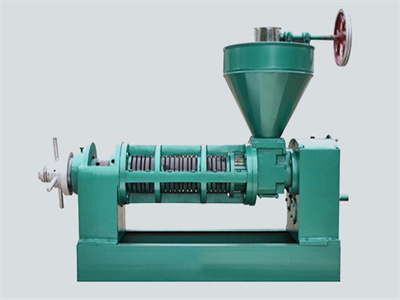

1-10ton day best selling coconut meat oil refinery plant machine

- Applicable Industries:Food and Beverage Factory

- After-sales Service:Provide Longlife Technical Support

- Dimension (L*W*H):1400*1300*1650mm

- Production capacity:6 ton per day

- Voltage:420V

- Weight:220kg

- Power:22-30kw

- Advantage:Low cost

- Raw material range:olive,pine nut,cotton seed,rape seed,linseed

- Transport Package: Export Wooden Crates

- Oil rate:45%-60%

set up a coconut oil refinery plant with low cost, coconut

but whichever way you use, the crude coconut oil you got should be refined by coconut oil refinery plant, and then sell in the supermarket. coconut oil refining process: crude coconut oil -- deacidification -- dehydration -- decolorization -- deodorization -- filteration -- refined coconut oil. coconut oil is a typical lauric acid oil.

coconut oil refinery plant, coconut oil refining, coconut

coconut oil is light yellow color oil obtained by mechanical screw pressing of dried coconuts. coconut oil refining plant has the input as raw coconut oil and gives output as rbd coconut oil. we are leading manufacturers and suppliers of coconut oil refining plants to process the crude coconut oil into refined coconut oil.

coconut oil processing machine offered by best oil mahcine

undertake 1-100tpd coconut oil processing project. offer turnkey coconut oil mill project plant (customized business plan, process design, equipment manufacturing, factory construction, and operation training ). coconut oil press machine / units for sale. capacity: 1-20ton/day (oil pressing), 1-5ton/d (oil refining); suitable raw material: copra (dired coconut)

scale business coconut oil extracting machine

coconut oil pressing machine for sale low cost premium quality. hi i'm from mindanao part of and i would like to ask the price of coconut oil pressing machine and coconut oil refining machine. how much it would cost me to start a small scale coconut oil refinery. we have actually a land of almost 100 hectares full of coconut trees and plan to maximize our business.

coconut oil fractionation machineoil seed pretreatment

fractionated coconut oil is coconut oil that has been processed or “fractioned” to create a very shelf-stable oil. the fraction of the oil that is used is very high in saturated fat, and this product can be used in a wide variety of ways.

coconut oil plant, coconut oil production line for making

coconut oil plant adopts twice pressing technology to produce coconut oil from the dried copra. the coconut oil production line mainly includes copra pretreatment and oil pressing process, oil refining process. copra cake produced after pressing can be used as animal feed. we provide 30-1000 tpd coconut oil processing machine and 1-600 tpd.

china coconut oil refinery machine, coconut oil refinery

china coconut oil refinery machine manufacturers,factory supply high quality coconut oil refinery machine products in best price from certified chinese machine for plastic manufacturers, machine for metal suppliers,automatic oil press machines are not only versatile, but also highly convenient to use.

coconut oil pressing machine 20-30ton per day for sale price

hongde machinery is a popular equipment manufacturer and supplier among vegetable oil production sector, well known for quality and services, distributing coconut oil pressing machine including screw oil pressing machine, integrated oil expeller with filter and refining machine at competitive price. besides, we also distributes turnkey project solutions for complete coconut oil production plant.

coconut oil machine, coconut oil machine suppliers

a wide variety of coconut oil machine options are available to you, there are 885 suppliers who sells coconut oil machine on sale, mainly located in asia. the top countries of supplier is china, from which the percentage of coconut oil machine supply is 100% respectively.

3 main steps to set up rbd coconut oil mill

coconut oil exists in two different types, the virgin coconut oil (vco) and deodorized oil (rbd).both vco and rbd vary in their mode of production, deodorized oil is made from dried copra while vco is made from fresh coconut meat. vco and rbd oil have different processing and production methods which affect their quality, flavor and appearance.

coconut oil extraction production line/copra oil

coconut oil extraction production line/copra oil extraction machine. oil expeller has the function of automatic temperature control, high oil yield, vacuum filtration, producing clean and hygienic oil. product description: 1. copra oil extraction machine coconut is palm tropical woody oil material,coconut pulp after drying is copra, the moisture content down to 6% -10% ,copra fat is 57% -75%, copra meal after extracting coconut oil can be used as animal feed.

manufacturering cooking oil making machine, edible oil

pretreatment and pressing plant. pretreatment is to adjust oil seeds into best state before pressing or solvent extraction. mainly includes cleaning, crushing, softening, flaking, puffing, cooking, drying, etc. different oil seeds need different pretreatment process, and then use oil press machine to get oil out.

small edible coconut oil refinery plant exported

we made a new deal on a small scale edible oil refinery plant with clients. this small oil refinery plant design is based on semi-continuous oil refining process. the clients want to set up the refinery plant for processing rbd coconut oil from dried copra for cooking purpose. before delivery, our inspectors checked the equipments of the coconut oil refinery plant carefully to.

coconut oil mill refining process oil mill machinery

coconut oil mill refining process consists of a series of refining procetures. the coconuts are at first cracked into pieces while the coconut meat is allowed to be dried. when it is dried, the coconut's meat or flesh is hydraulically pressed at 100 130 degrees in order to extract the oil.

find professional coconut oil processing at oil mill plant

kmec is the leading company in the field of coconut oil processing.we design complete coconut oil plant, we offer quality coconut oil processing equipment, most importantly, we support state of art coconut oil processing technologies.. coconut oil processing. coconut oil processing process. well dried copra with a moisture content not exceeding 6 per cent is cleaned well from any foreign matter.

20tpd coconut oil extracting and refining plant

coconut oil extracting and refining plant. we have helped set up a coconut oil extracting and refining plant. this plant is start building in november. below are the pictures of the coconut oil extracting and refining plant under building. vedio of the coconut oil extracting and refining installation site

refined coconut oil and detailed refing process

coconut oil refining process. the refined organic coconut oil is processed using the organically approved methods of physical extraction and refining. for the extraction step, the coconuts are broken into pieces and the coconut meat is allowed to dry, and once it is dried, the meat or flesh of the coconut is hydraulically pressed at 100 130.

oil expeller screw press on namibia and hot sale

oil mill machinery, oil machinery manufacturer. oil expeller vk-20-3to4tpd. model : vk-20. shreeji expeller industries is the top mostn manufacturer and supplier of oil extraction machinery and components to oil extraction plants, oil mill, oil refinery plants and bio-diesel plant production houses.

press qualified coconut oil with our best coconut oil machine

buy your coconut oil machine and make big money for your own.generally speaking coconut oil can be extracted by chemical solvents, or pressed directly from coconut or copra. hot pressing coconut oil which uses an coconut oil machine under high-temperature conditions is a preferred method for those seeking an extraction process that doesn't involve chemical solvents.

cooking oil refinery batch type vegetable oil refinery

we present one of the most developed cooking oil refinery plant for processing of edible oil. there are primarily involved two types of processing- batch type and continuous. through these processes, the oil is separated from impurities and other materials that can make it unfit for edible purpose.